Terminal and connector for photovoltaic module connector

A technology of photovoltaic modules and connectors, which is applied in the direction of two-component connection devices, connections, photovoltaic power generation, etc., and can solve problems such as lack of detailed considerations, affecting the safe use of photovoltaic modules and photovoltaic arrays, and burnout of connectors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The structural features and advantages of the present invention are described in detail below in conjunction with the accompanying drawings.

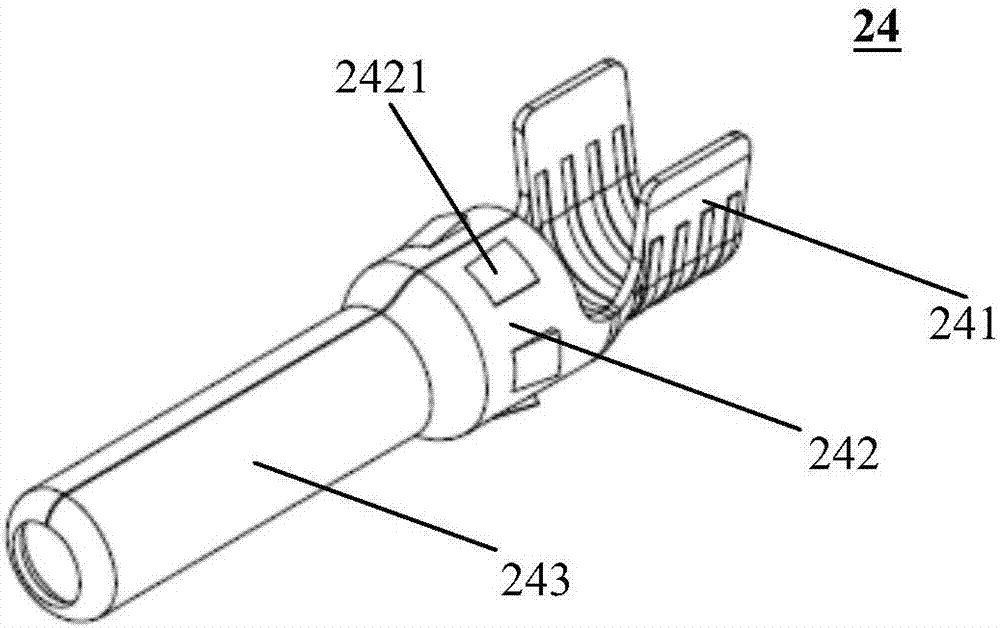

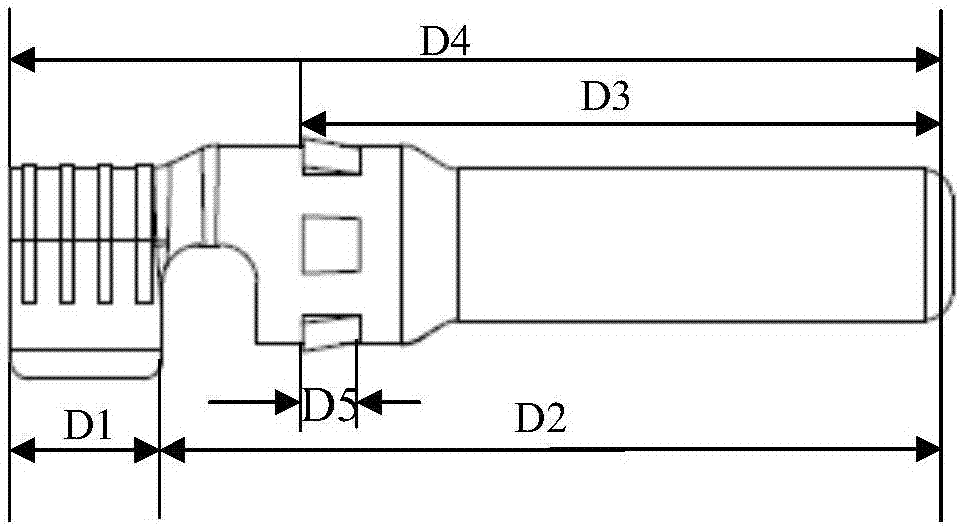

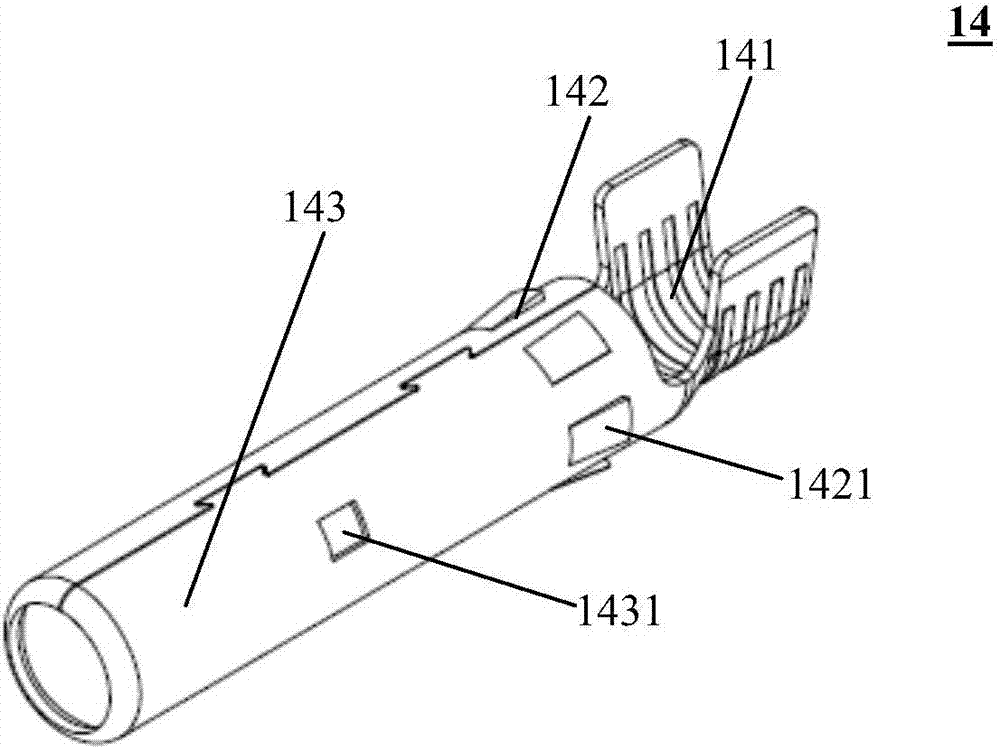

[0018] The photovoltaic module connector includes a male plug and a female plug. Therefore, the terminal for the photovoltaic module connector of the present invention also includes a male plug terminal, which is a pin, and a female plug terminal, which is a plug sleeve. Refer to Figure 1A Shown is a schematic structural diagram of a pin 24 (male terminal) of a photovoltaic module connector terminal according to an embodiment of the present invention. The pin 24 includes a first riveting portion 241, a first connection fixing portion 242 and a first plug The connecting part 243, the first riveting part 241 is fixedly connected with the plastic shell of the connector, and the first connection fixing part 242 is provided with a plurality of first wedge-shaped protrusion structures 2421, which are locked with the pins inside the conn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com