Resistance repair construction for current sensing component and manufacturing method thereof

A technology of current sensing, manufacturing method, applied in the direction of resistors, electrical components, non-adjustable metal resistors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

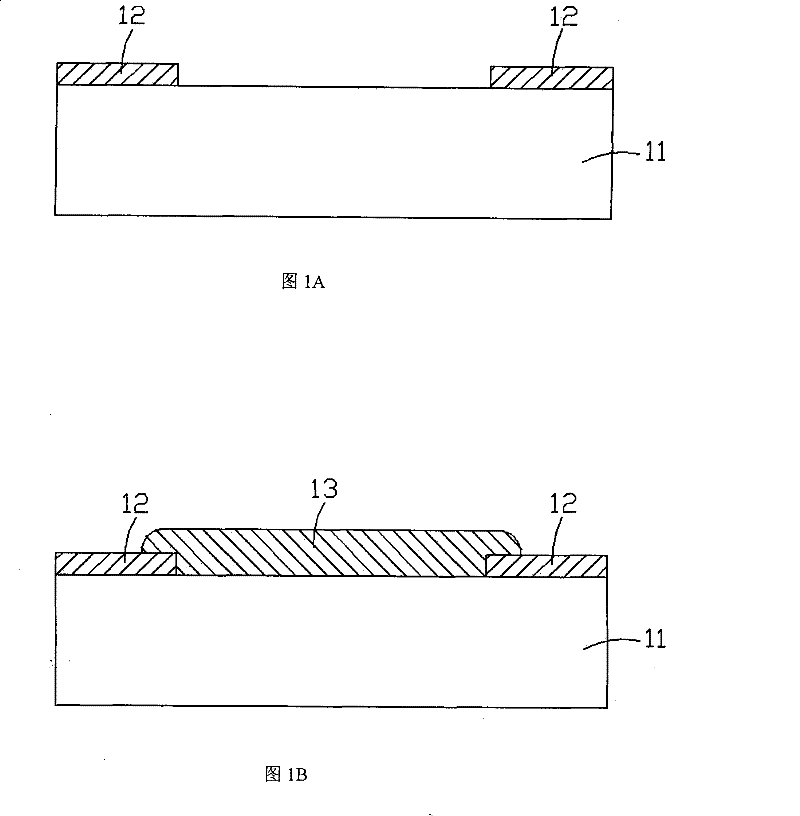

[0024] The features of the present invention can be clearly understood by referring to the drawings and the detailed description of the embodiments.

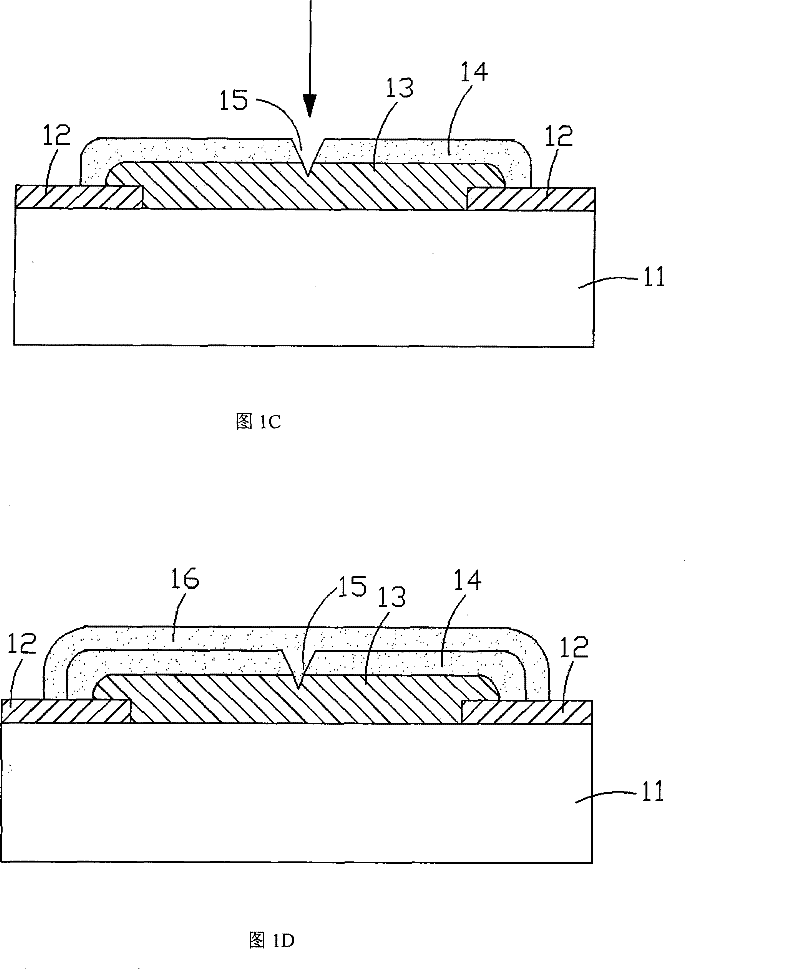

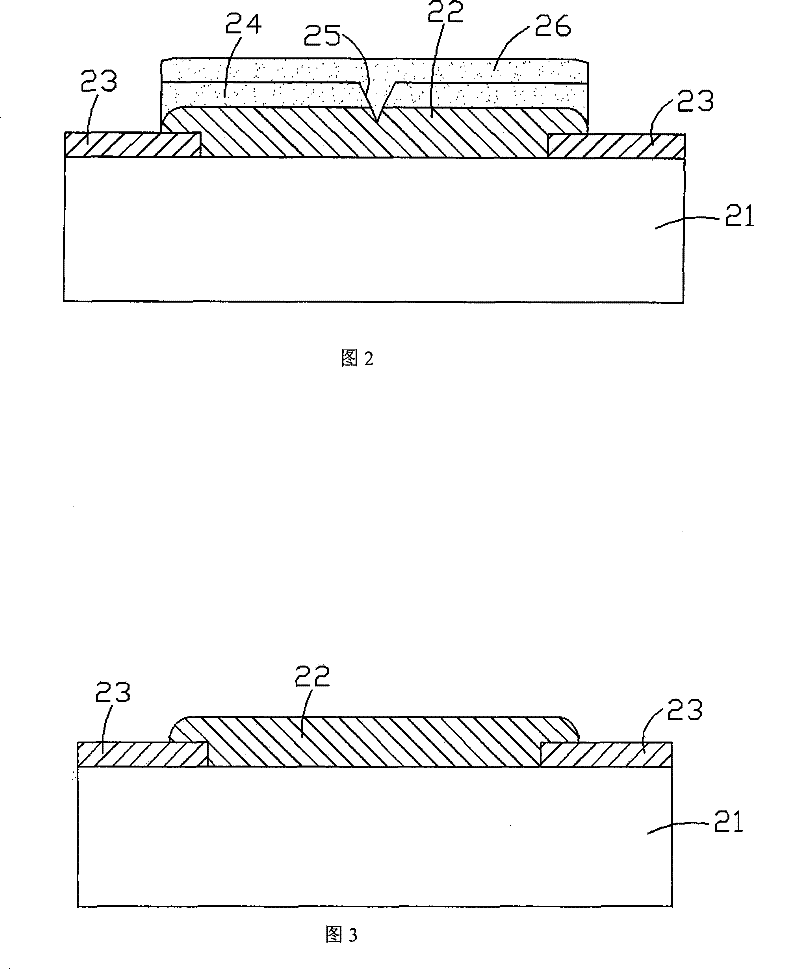

[0025] The resistance repairing structure of the current sensing component of the present invention and its manufacturing method, wherein, the current sensing component 2, such as figure 2 As shown, at least one resistance layer 22 is mainly provided on the surface of a substrate 21, and separate electrode layers 23 are provided on both ends of the surface of the substrate 21, and the resistance layer 22 is also provided with circuit patterns (not shown in the figure). ), the two electrode layers 23 are arranged on both sides of the resistance layer 22, and are electrically connected with the resistance layer 22 to establish a current path.

[0026] The key points of the present invention are: the resistance layer 22 is provided with a first protective layer 24, the surface of the resistance layer 22 and the first protection la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com