Multihead multidirectional conjunction box

A junction box, multi-head technology, applied in the direction of connection, conductive connection, electrical components, etc., can solve the problems of untidy and beautiful appearance, poor conduction, poor contact, etc., to achieve strong ability of conductive lines to be smooth, easy to manufacture, easy to assemble and disassemble Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

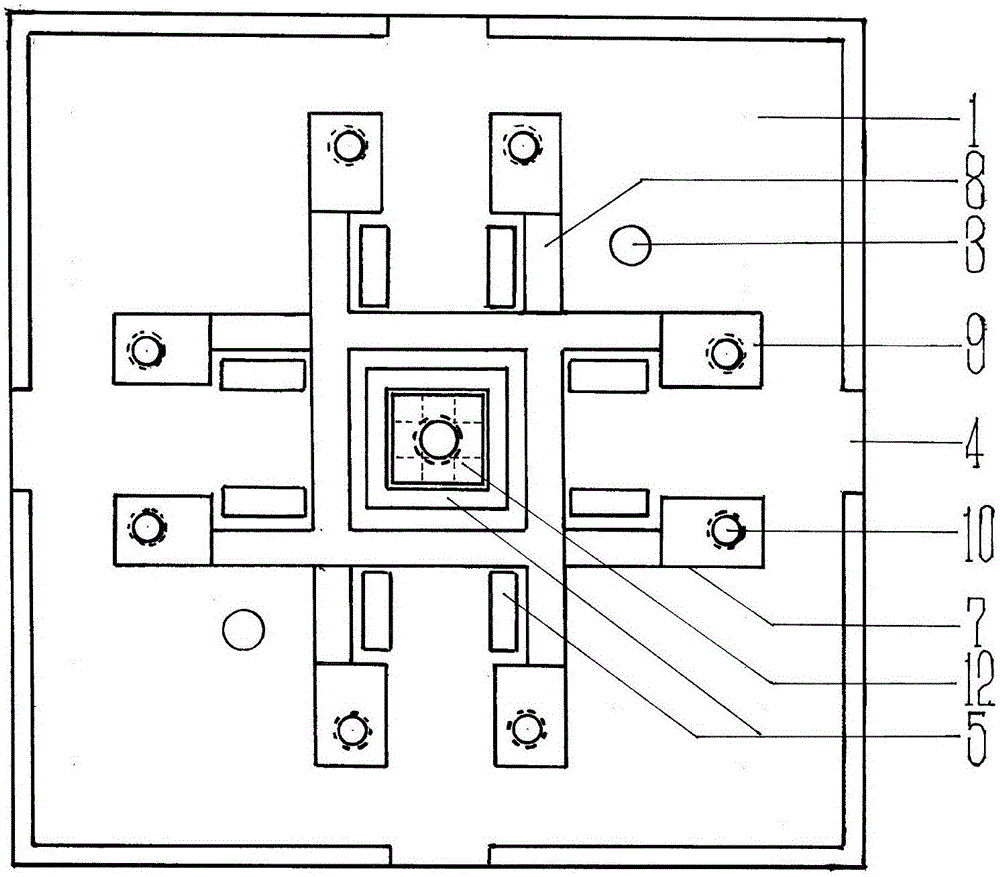

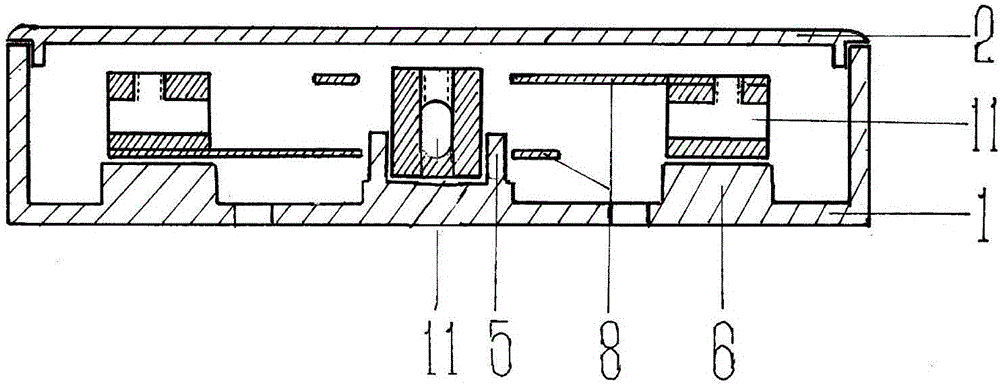

[0020] Below in conjunction with accompanying drawing, the present invention will be described in further detail:

[0021] Such as figure 1 , figure 2 As shown, the box seat 1 of the multi-head multi-directional junction box is a four-sided vertical wall, and the center of each vertical wall is provided with an incoming hole 4, and the inner bottom surface is provided with a solid hole 3 that penetrates outward, and the positioning connection module 7 and the ground wire terminal The pallet 6 of 12 and the groove box of the positioning stall post 5 are incarcerated with the flat box cover 2 to form a junction box shell. The connection module 7 is two well-shaped hollow copper plates with single ends, and the terminals are welded with a terminal 9 having a wire insertion hole 11 and a wire crimping hole 10 . The crimping wire holes 10 on the two connecting modules 7 are respectively arranged from the front and the back. The ground wire terminal 12 is a square shape, and fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com