Ultrathin connector combination structure

A connector combination, ultra-thin technology, applied in the direction of connection, connecting device parts, contact parts, etc., can solve the problems of thick thickness and complex connector structure, and achieve simple production and storage, simple structure, and small size. effects of miniaturization and miniaturization of device use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

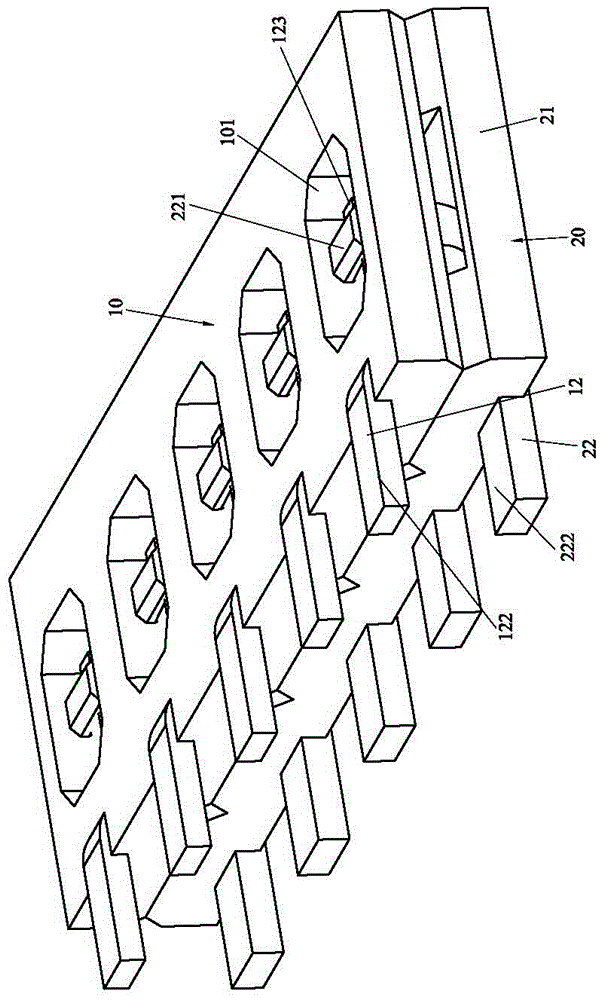

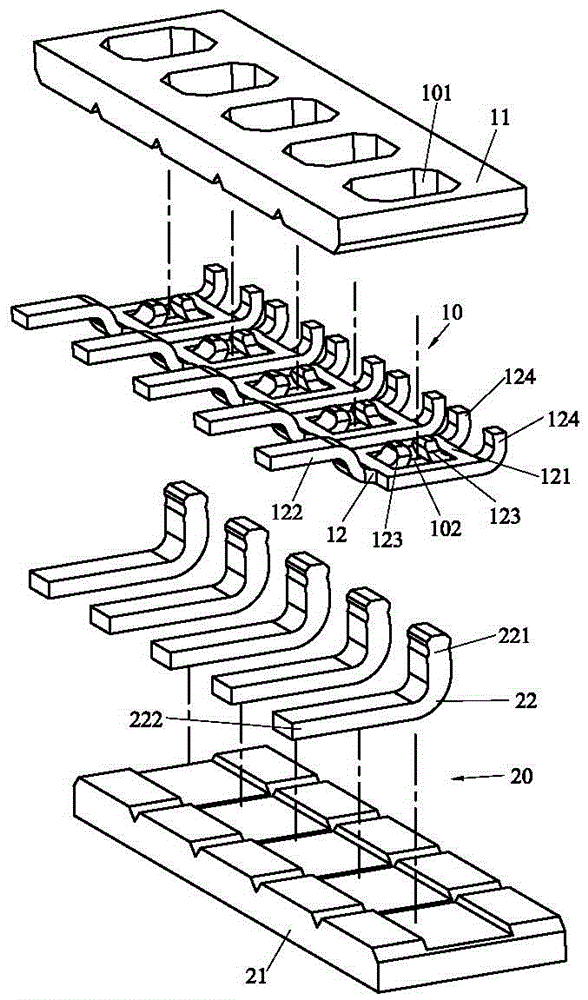

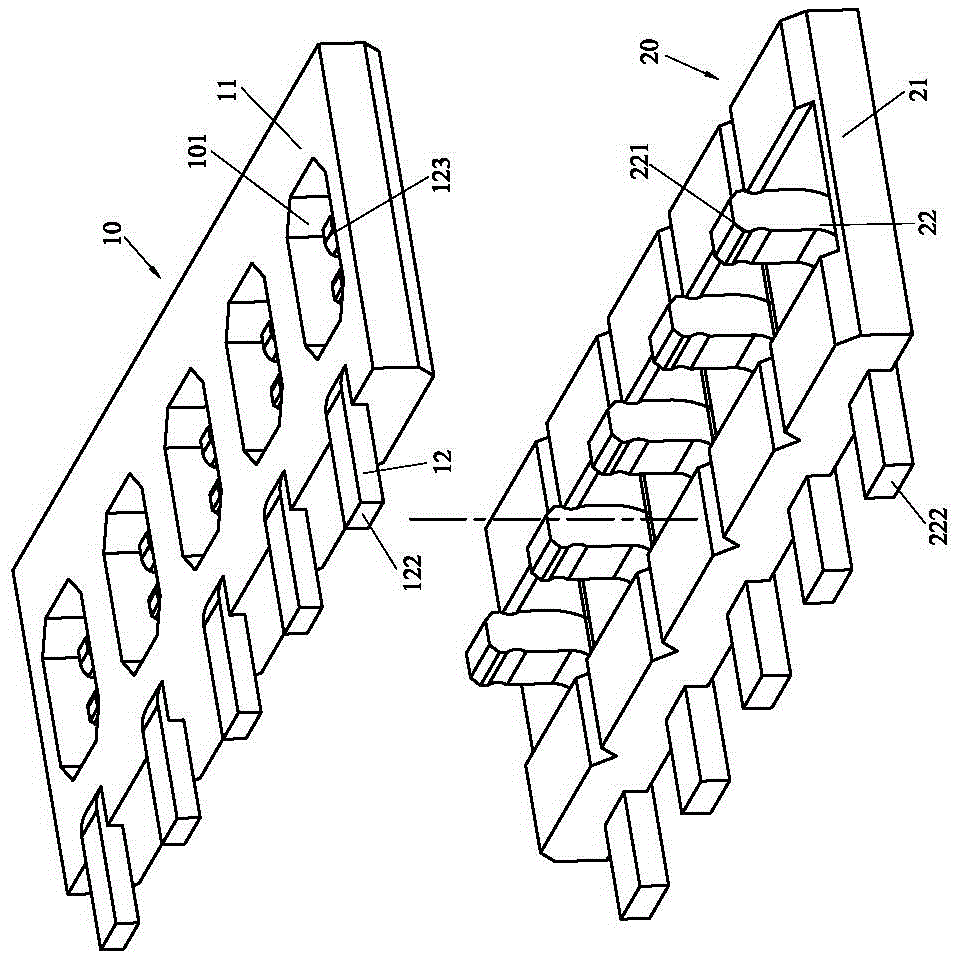

[0029] Please refer to Figure 1 to Figure 5 As shown, it shows the specific structure of the first preferred embodiment of the present invention, including a receptacle connector 10 and a plug connector 20 .

[0030] The receptacle connector 10 includes a first insulating plate 11 and at least one first terminal 12, the upper and lower surfaces of the first insulating plate 11 are penetrated with slots 101, and the first terminal 12 is embedded and fixed with the first insulating plate 11. Together, the first terminal 12 includes a frame part 121 and a first welding part 122 that are integrally formed and connected. The hole 102 is located in the aforementioned slot hole 101 , the edge of the insertion hole 102 is bent to protrude from the elastic contact portion 123 , and the first welding portion 122 protrudes out of the first insulating board 11 .

[0031] The plug connector 20 includes a second insulating plate 21 and at least one second terminal 22, the second insulatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com