High-power semiconductor laser chip conductive heat dissipation package heat sink

A semiconductor and laser technology, applied in the field of high-power semiconductor laser chip conduction heat dissipation package heat sink structure, can solve the problems of shortened device life, long heat dissipation path, decreased output efficiency, etc., to reduce thermal resistance and internal temperature rise, increase The effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

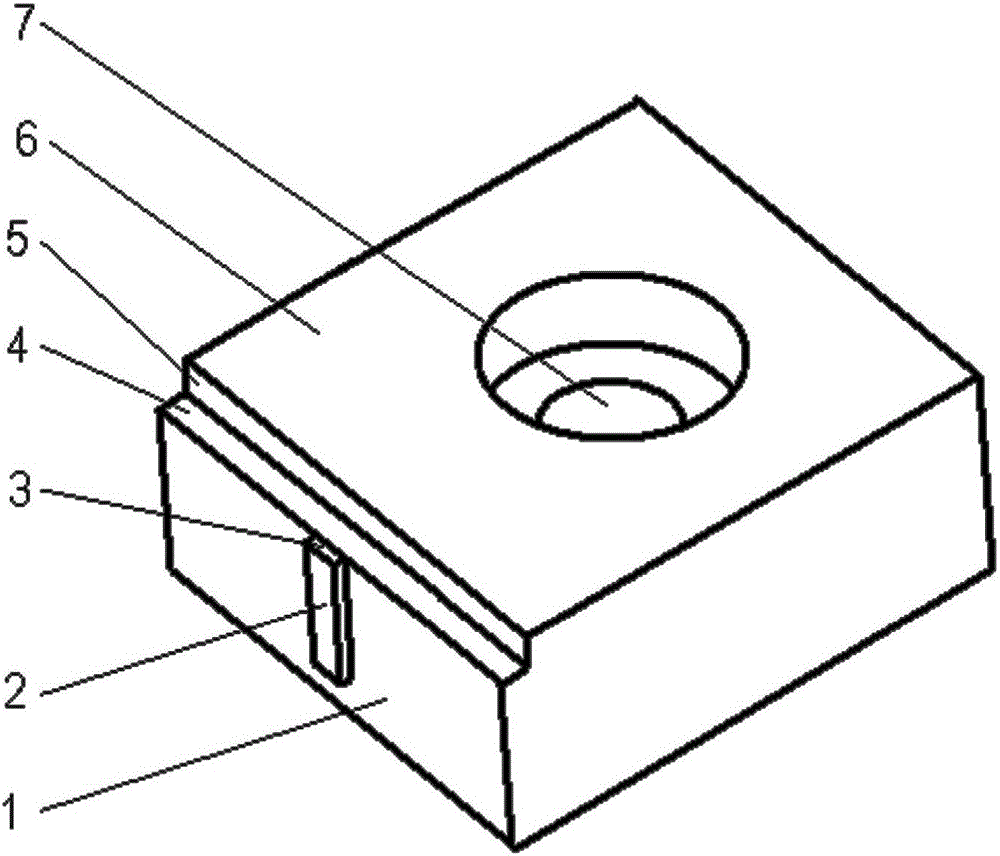

[0007] As shown in the accompanying drawings, the semiconductor laser chip conduction heat dissipation packaging heat sink has a chip welding surface (1), a stepped plane (4), a stepped elevation (5), and a fixing hole (7). The semiconductor laser chip (2) is welded on the chip welding surface (1), the light emitting end surface (3) of the chip is aligned with the step plane (4), and the fixing holes (7) are used to fix the heat sink to other heat dissipation surfaces. The steps composed of the step plane (4) and the step elevation (5) effectively increase the heat dissipation capacity of the semiconductor laser chip (2), and the smaller step plane (4) width and the larger step elevation (5) height have It is beneficial to obtain a smaller thermal resistance of the chip package.

[0008] The present invention is described below in conjunction with an example. The semiconductor laser chip (2) with a cavity length of 4mm and an output power of 10W is soldered to the chip welding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com