Bus terminal accessory of ethylene-propylene insulation copper pipe

A technology of ethylene-propylene insulation and insulating tubes, which is applied in the direction of cable terminals, busbar installation, electrical components, etc., to achieve uniform insulation shielding, prolong creepage distance, and save subsequent processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

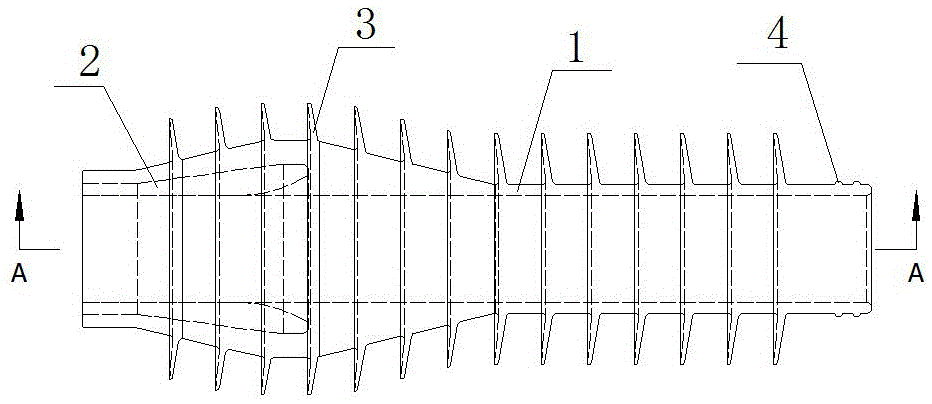

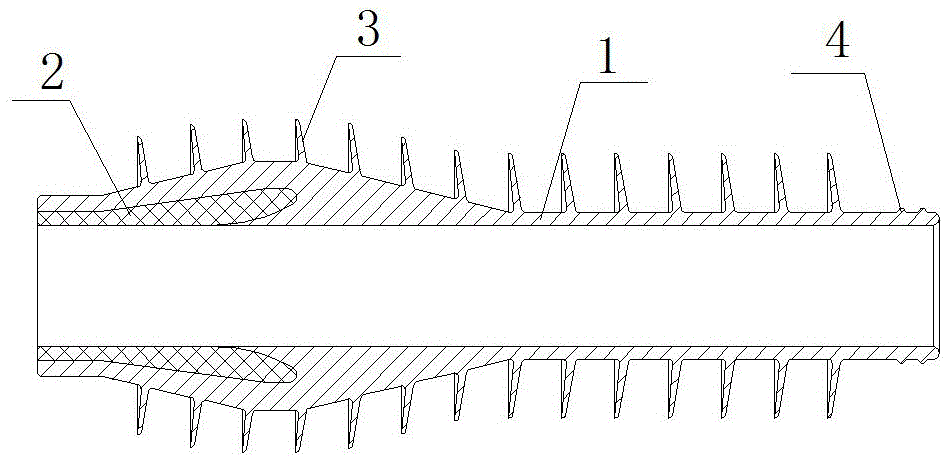

[0014] The ethylene-propylene insulated copper tube busbar terminal accessories of the present embodiment, such as figure 1 with figure 2 As shown, it includes: a hollow insulating tube 1 and a semiconductive stress cone 2 located at one end of the insulating tube 1; the semiconductive stress cone 2 is hollow in the shape of a truncated cone, and the end with a large radius faces the insulating tube 1; the semiconductive stress cone 2 is The insulating tube 3 is wrapped; the outer surface of the insulating tube 3 has a plurality of sheds 3 . The middle of the insulating tube 1 has a protrusion that copes with the stress generated by the shape change. The other end of the insulating tube 1 has a ring 4 of increased surface area.

[0015] The insulating tube 1 is made of liquid silicone rubber, which is formed by molding at high temperature and cured. The final semi-conductive stress cone adopts the shape of a bell mouth and overlaps with the insulating shield of the insulati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com