Automotive Lumbar Motor

A waist support, automobile technology, applied in the direction of electromechanical devices, electrical components, electric components, etc., can solve the problems of easy failure of Hall circuit, easy material leakage, no support, etc., to save materials and assembly costs, and prolong service life. , the effect of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

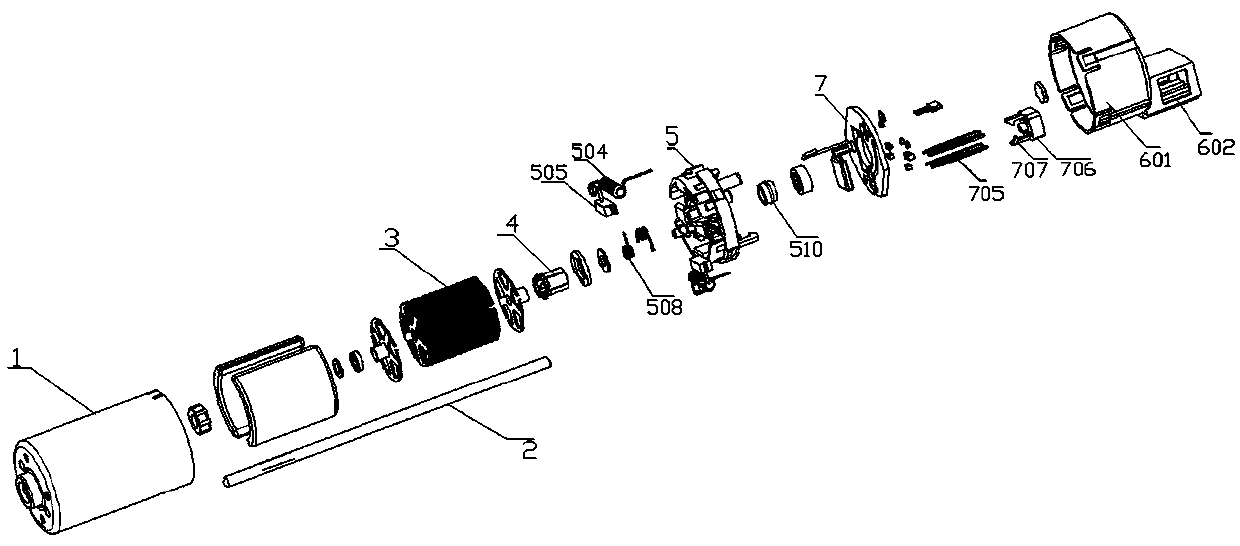

[0021] Accompanying drawing has shown structure of the present invention, further illustrates its relevant details below again in conjunction with accompanying drawing. See attached figure 1 , the automobile lumbar support motor includes a stator 1, a rotor, a PCB assembly 7, a plug connector 6 and a rubber cover 5, the rotor includes a rotating shaft 2, a rotor core 3 fixed on the rotating shaft 2 and a commutator 4, The windings wound on the rotor core 3.

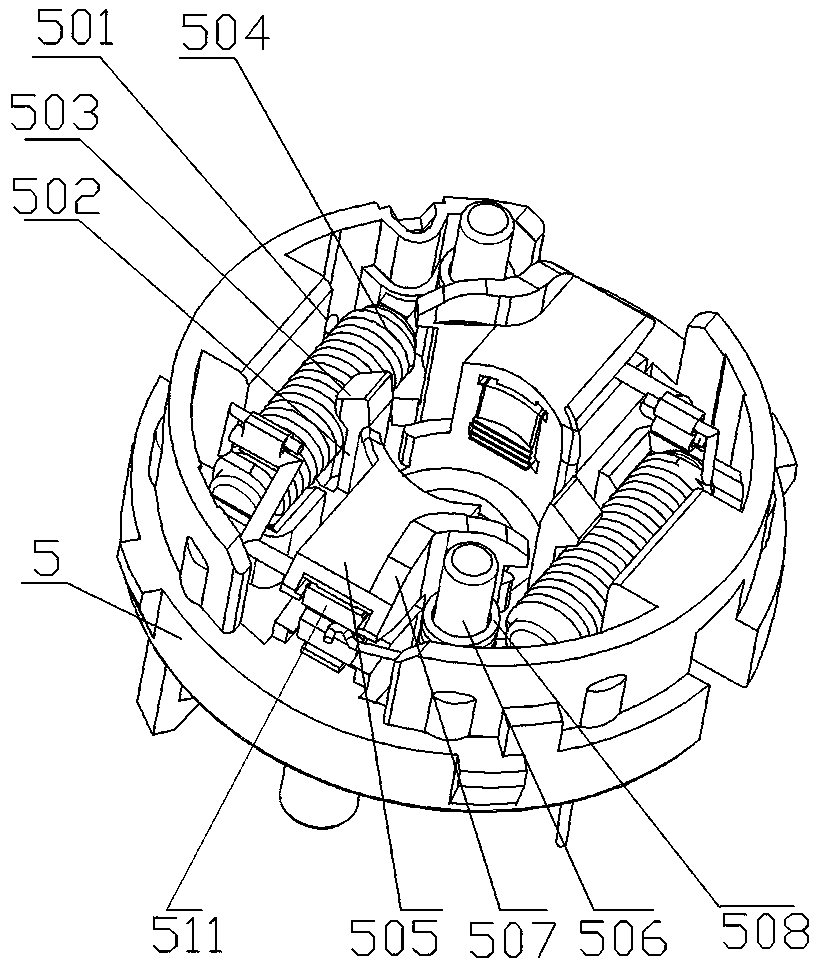

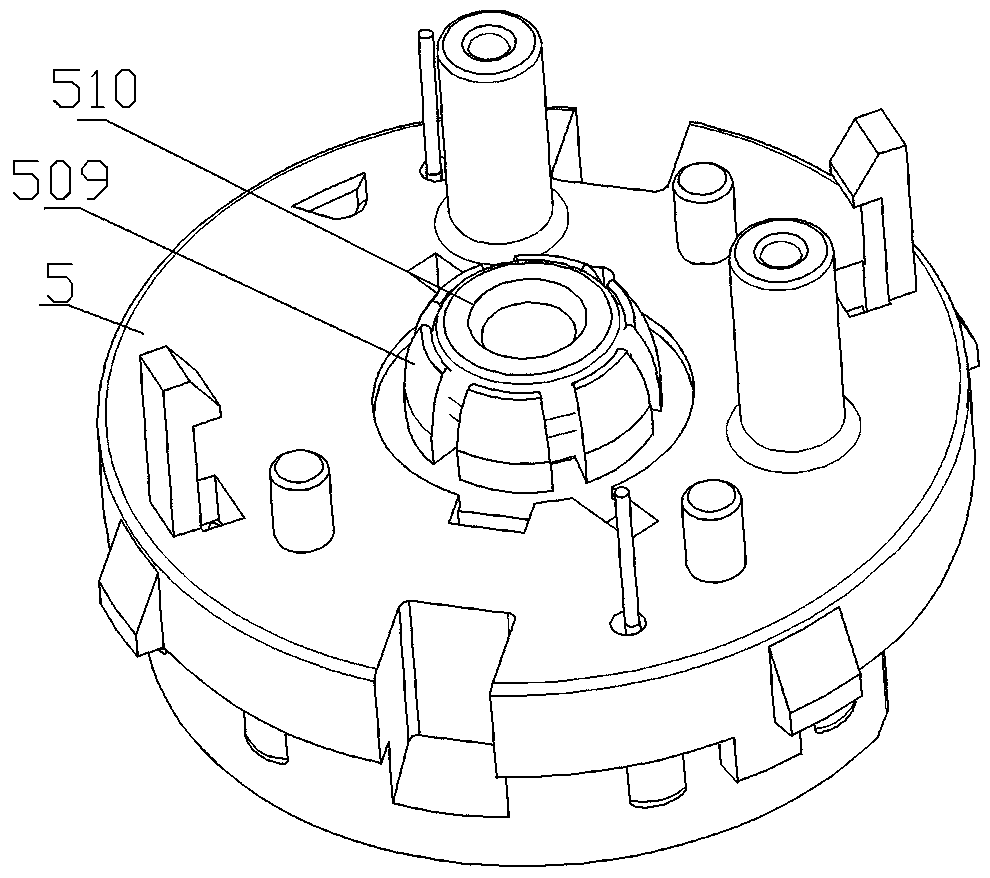

[0022] See attached figure 2 , the rubber cover 5 is provided with an inductance card slot 501, one side of the inductance card slot 501 is an elastic buckle 502, and the upper end of the elastic buckle 502 is provided with a barb 503, the inductor 504 is assembled in the inductance card slot 501, and It is limited and fixed by the barb 503; when installing, press the inductor, stretch the elastic buckle 502, so that the inductor is placed in the inductor slot 501, and then the inductor is squeezed and fixed by the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com