A horizontal feeding device for a sticking and inserting machine

A feeding device, horizontal technology, applied in the direction of electrical components, electrical components, etc., can solve the problems of no bending and cutting leads, improve market competitiveness, large temporary space, etc., achieve compact structure, improve market Competitiveness and small temporary space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be further described below with reference to specific embodiments and accompanying drawings.

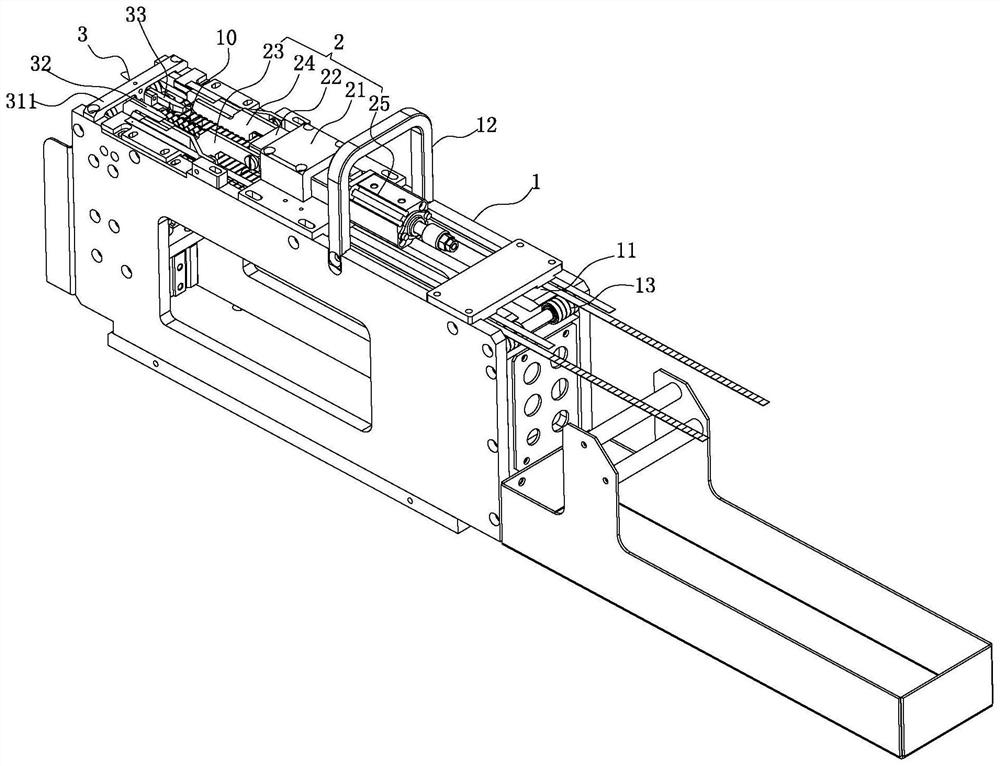

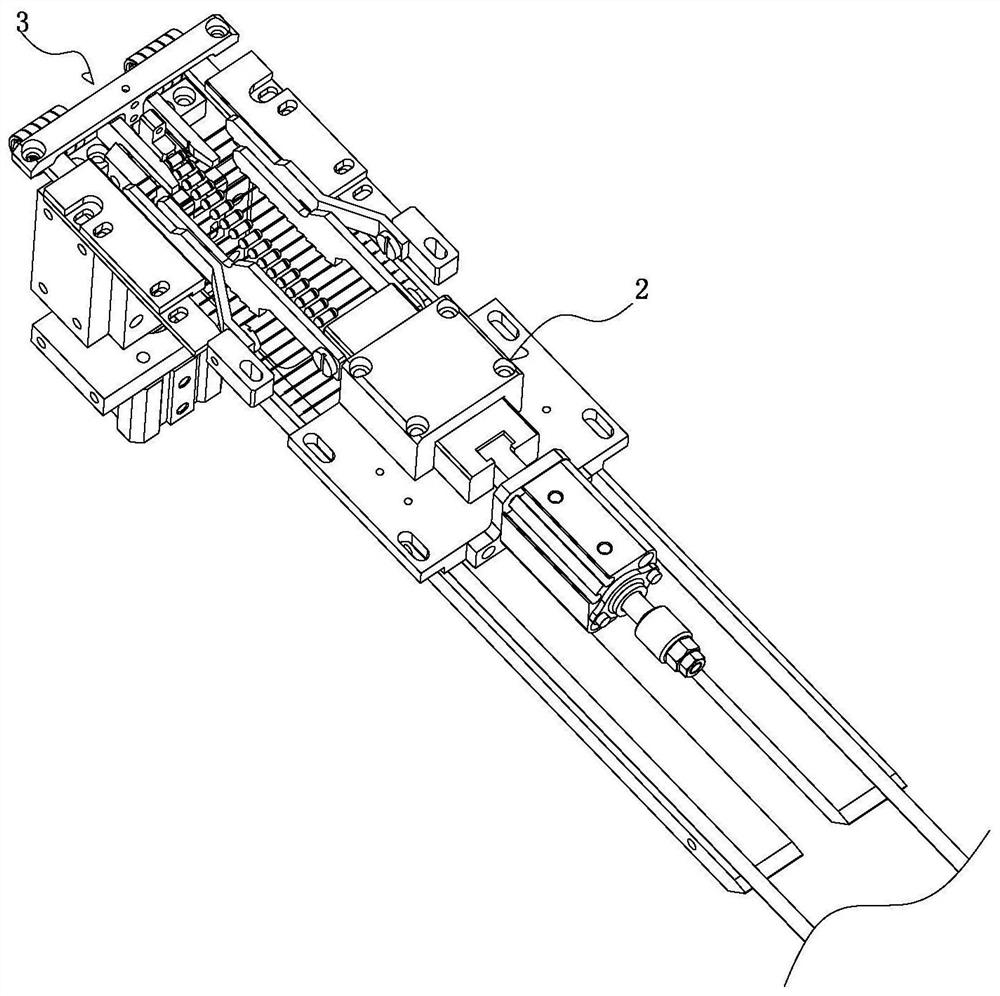

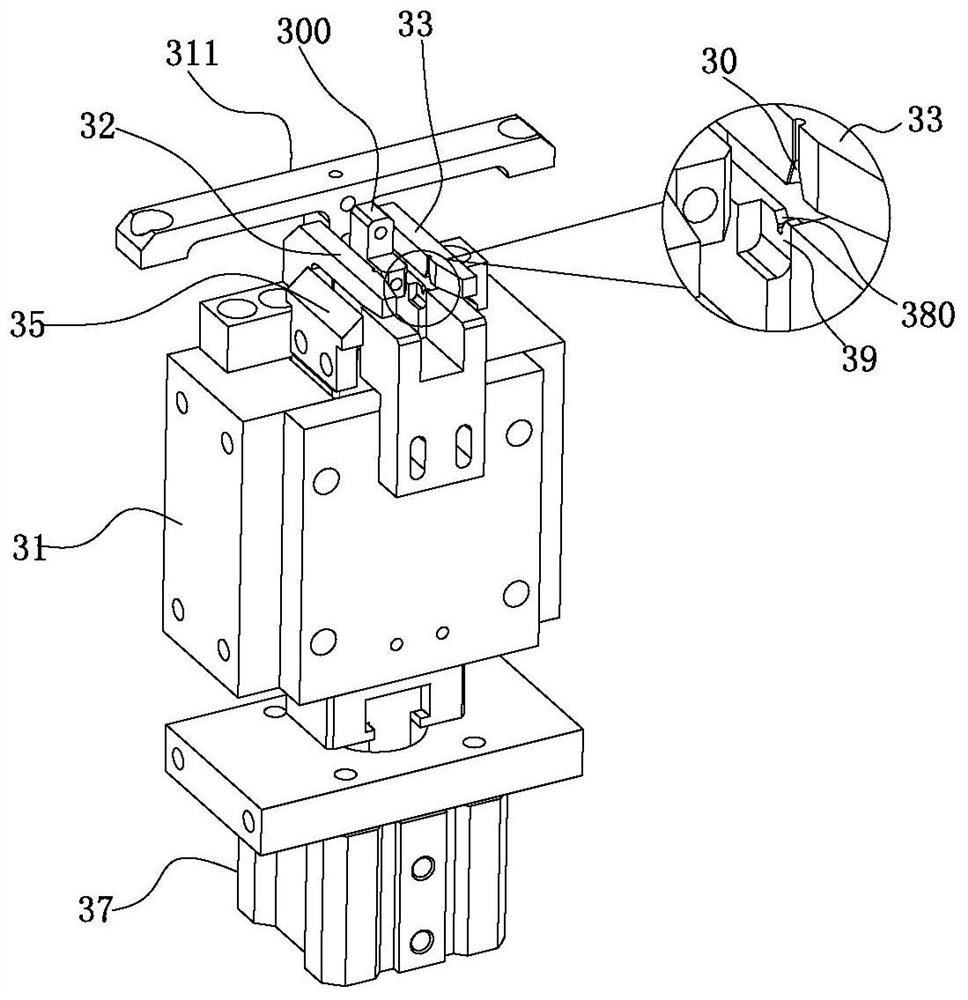

[0023] See Figure 1-4 As shown, it is a horizontal feeding device for a patching machine, which includes a machine base 1 , a feeding mechanism 2 and a bending and cutting mechanism 3 mounted on the machine base 1 .

[0024] The machine base 1 is provided with a transverse trough 11 for the electronic components 10 to pass through, and the rear end of the machine base 1 is provided with a number of bearings 13 corresponding to the transverse chutes 11 . The electronic components are resistors, the entire row of which passes through the transverse trough 11 .

[0025] The machine base 1 is provided with a foldable handle 12. When in use, the handle 12 can be directly opened to directly lift and assemble the present invention, which is very convenient to operate and use.

[0026] The feeding mechanism 2 is installed on the machine base 1; specifical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com