Underground components with amorphous coating

An amorphous, coating technology that can be used in coatings, metal material coating processes, layered products, etc., to solve problems such as weakening and catastrophic failure of drill pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

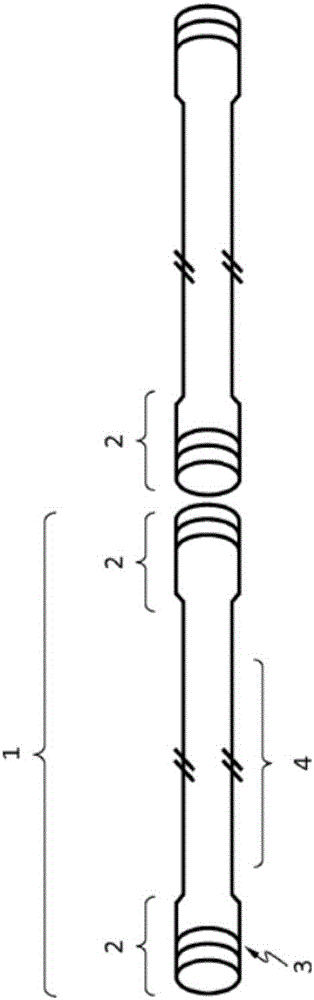

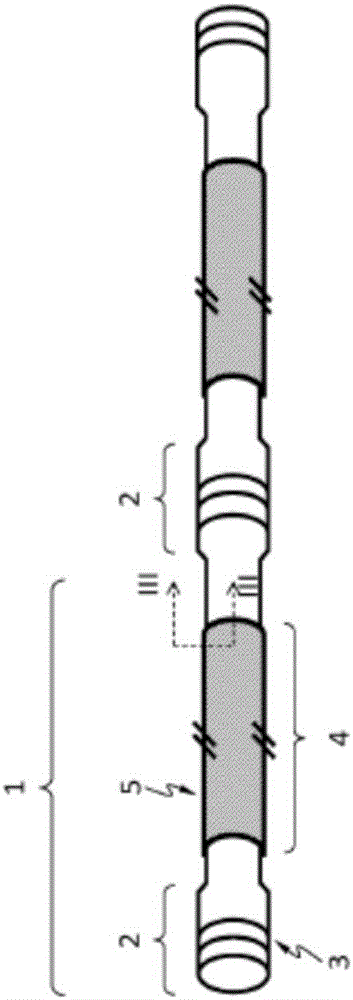

[0057] The disclosure herein may be useful in improving protection and wear resistance of subterranean service components, such as drill pipe or production tubing, without increasing the risk of component failure.

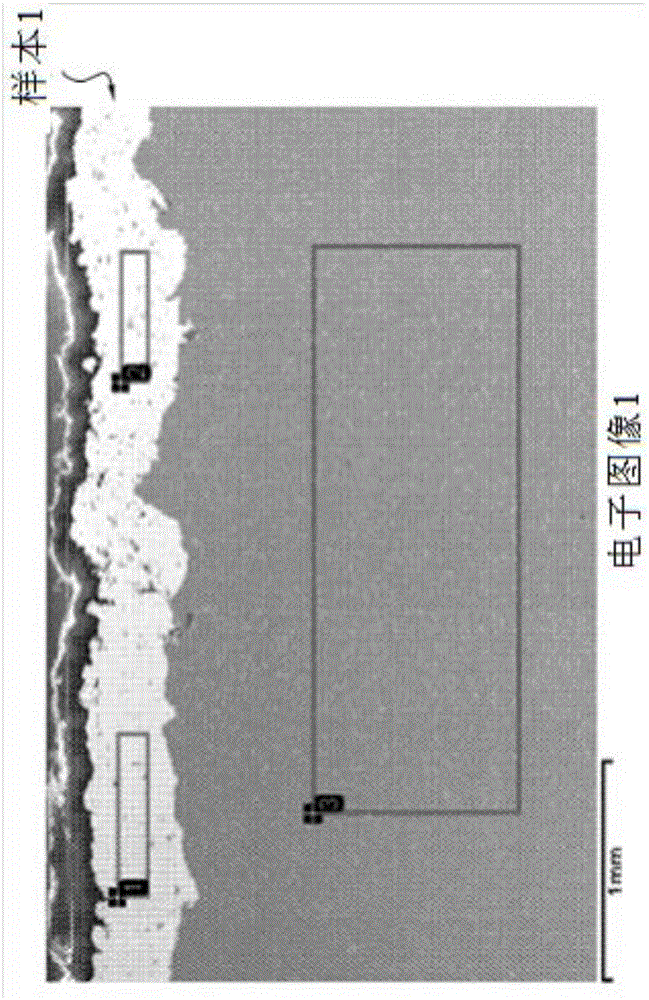

[0058] According to an embodiment, at least a portion of a component (e.g., drill pipe, production tubing) for subterranean use may be thermally sprayed with a coating having a high elastic strain limit that exceeds the strain of the component in subsurface use (e.g., drilling down the drill pipe) through the bending of the drill pipe). The portion thermally sprayed with the coating may include a portion of a component that may come into direct contact (such as the midsection of a drill pipe), or may scrape subterranean structures. The coating can include an amorphous metal alloy. The coating may comprise an at least partially amorphous, non-crystalline, disordered atomic scale structure. The coating may have a higher hardness than the surface of the component on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com