Device for injecting medium, and exhaust gas after-treatment installation

An exhaust gas post-treatment and medium technology, which is applied in fuel injection devices, special fuel injection devices, exhaust gas treatment, etc., can solve the problems of increased loss, adhesion and abrasion, piston radial load, etc., and achieves low loss and small Force consumption, avoiding the effect of lateral forces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

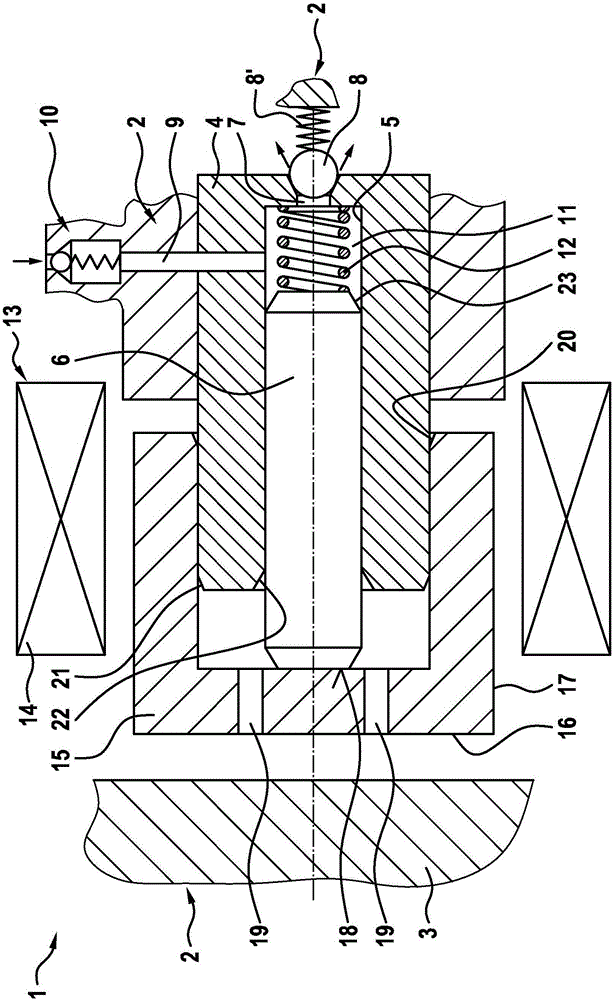

[0016] The drawing shows in a simplified longitudinal section a device 1 which is configured as a pump-nozzle system and is part of an exhaust gas aftertreatment device for exhaust gas aftertreatment of a motor vehicle internal combustion engine. The device 1 has a housing 2 which is currently constructed in multiple parts. Here, the housing 2 has a first housing part 3 placed outside and a second housing part 4 built in. The housing part 4 has a piston receiving portion 5, and the piston 6 is slidably supported in the piston receiving portion 5 in an axially movable manner. The piston receptacle 5 here has an inner diameter substantially corresponding to the outer diameter of the piston 6 so that an advantageous sliding support for the piston 6 is produced. The piston receiving portion 5 is configured as a pocket drilled hole or a pocket recessed portion, so that the piston receiving portion 5 has a contracted diameter at one end. This reduced diameter here forms an injectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com