Fuel pump and method for operating a fuel pump

A fuel pump and fuel technology, which is applied to fuel injection pumps, components of pumping devices for elastic fluids, fuel injection devices, etc., can solve problems such as damage to volumetric efficiency and function, and achieve compact and save structure and cost. , the effect of saving cost and space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

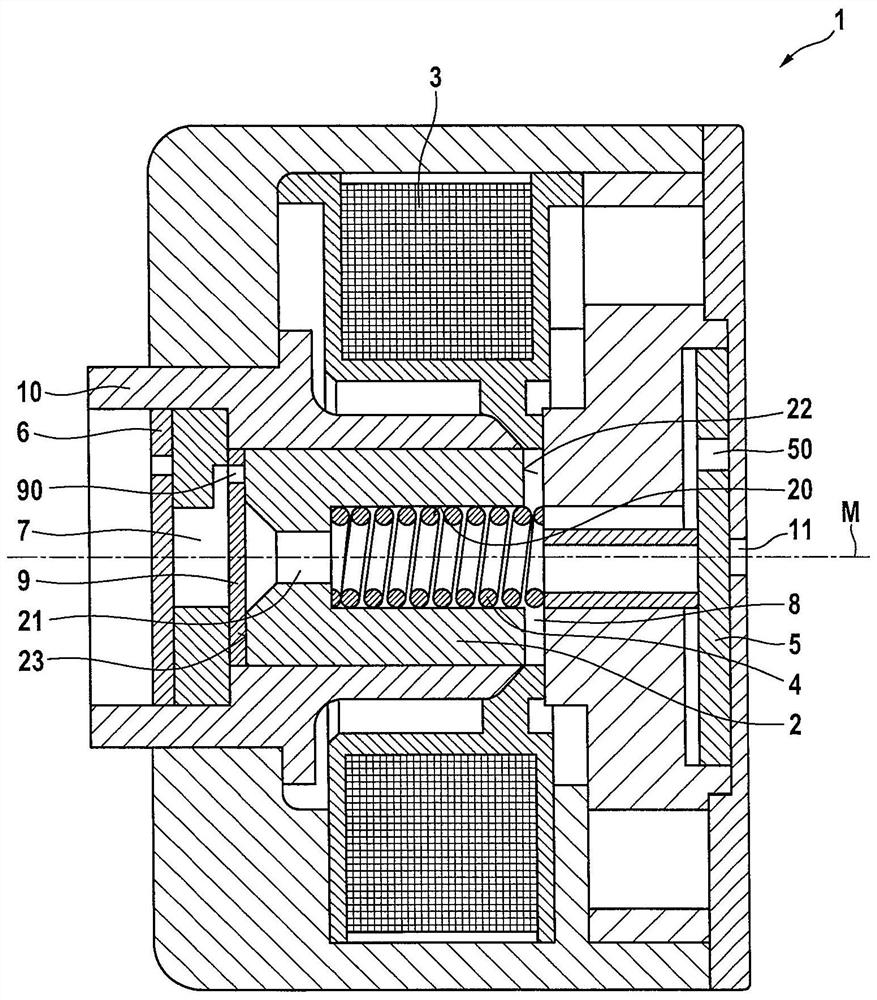

[0023] Refer below figure 1 A fuel pump 1 according to a first preferred embodiment of the present invention will be described in detail.

[0024] as from figure 1 As can be seen in , the fuel pump 1 according to the invention is designed as an electromagnetic piston pump and accordingly has a piston 2 , a solenoid coil as actuator 3 for actuating the piston 2 and a magnetic coil as an actuator for actuating the piston 2 . 2 The spring element of the reset element 4 resets into the initial position. The fuel pump 1 according to the invention also comprises a first inlet valve 5 , an outlet valve 6 , a delivery chamber 7 , a prechamber 8 and a second inlet valve 9 .

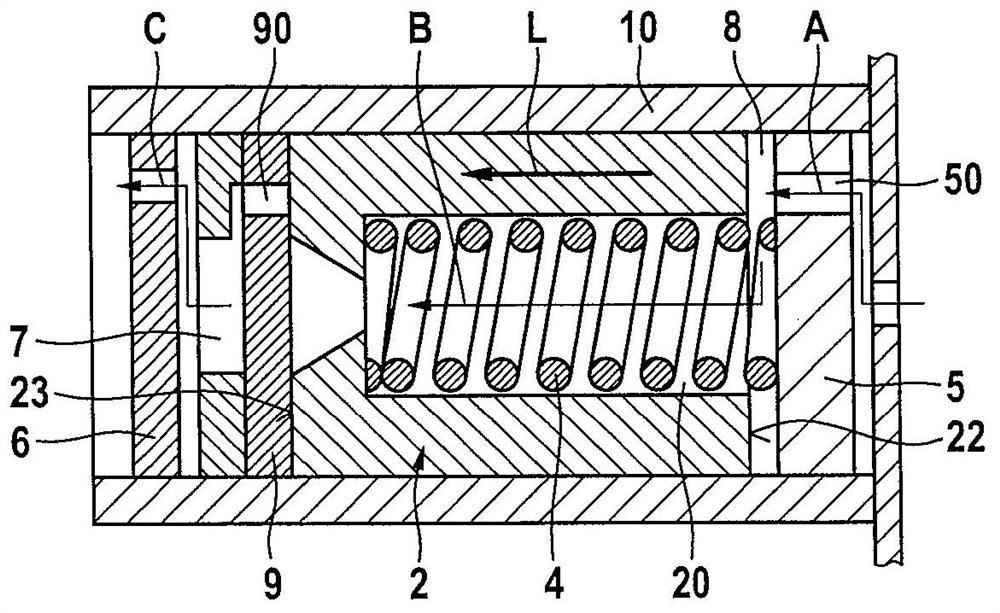

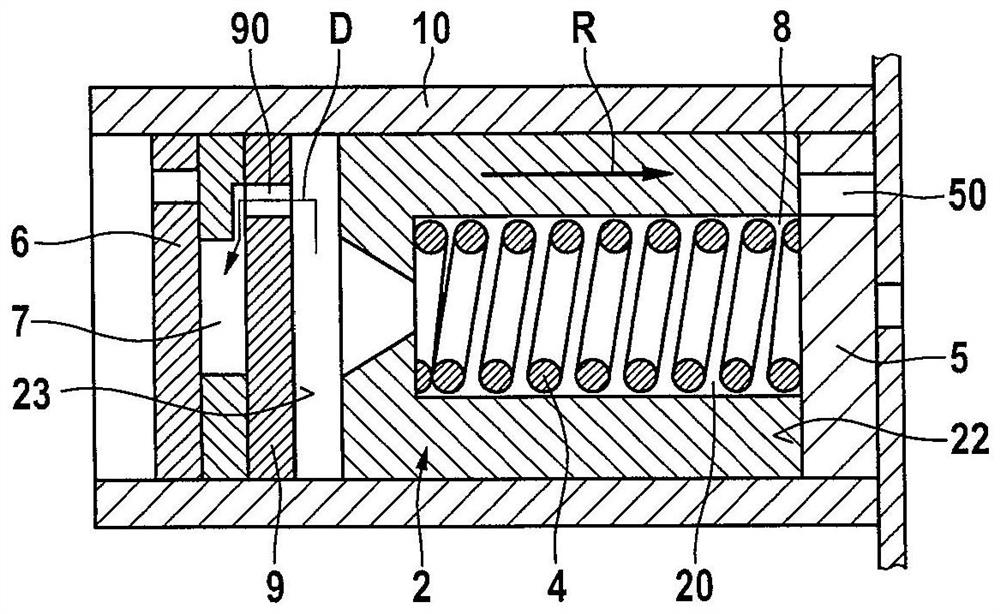

[0025] The piston 2 is cylindrical and has a through-bore 21 formed therein, which separates the delivery chamber 7 from the pre-chamber 8 , wherein the delivery chamber 7 and the pre-chamber 8 are arranged in a common cylinder component 10 . The piston 2 is likewise arranged in the cylinder component 10 . Fu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com