Roller-bearing arrangement and a wind turbine

A technology for roller bearings and bearing devices, applied in roller bearings, wind power engines, rolling contact bearings, etc., can solve problems affecting the smooth operation of bearings, and achieve the effects of high stability, less wear and long life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

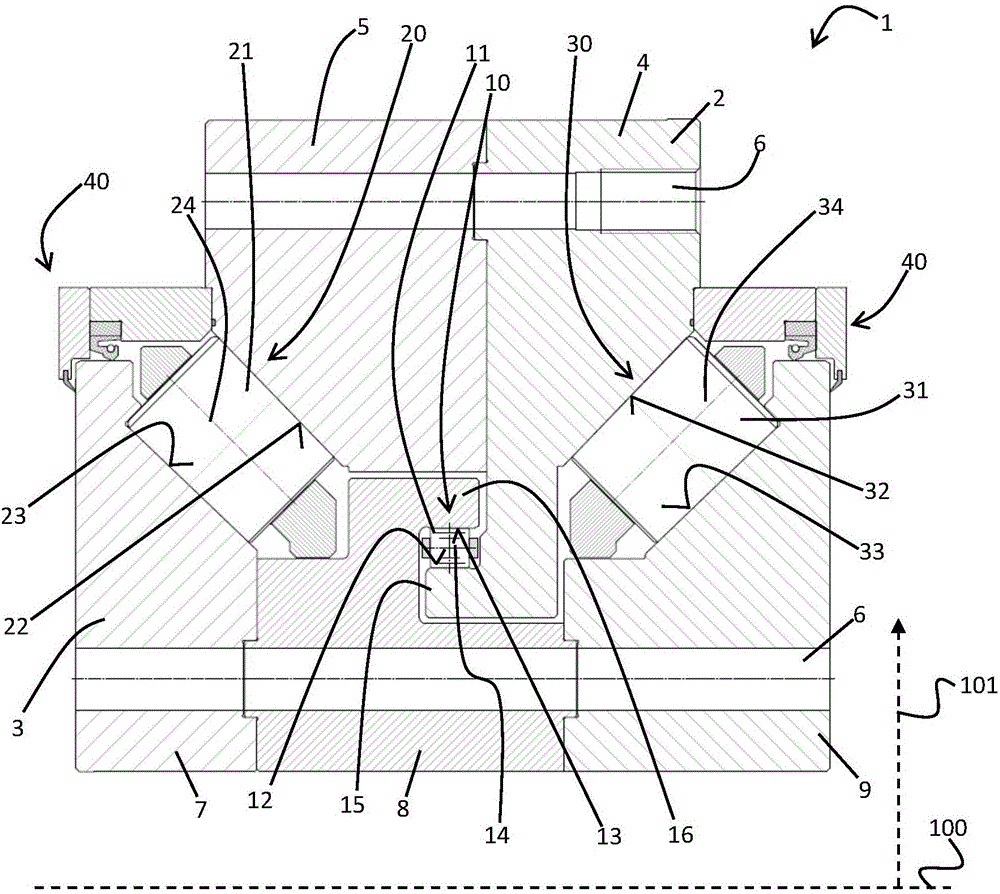

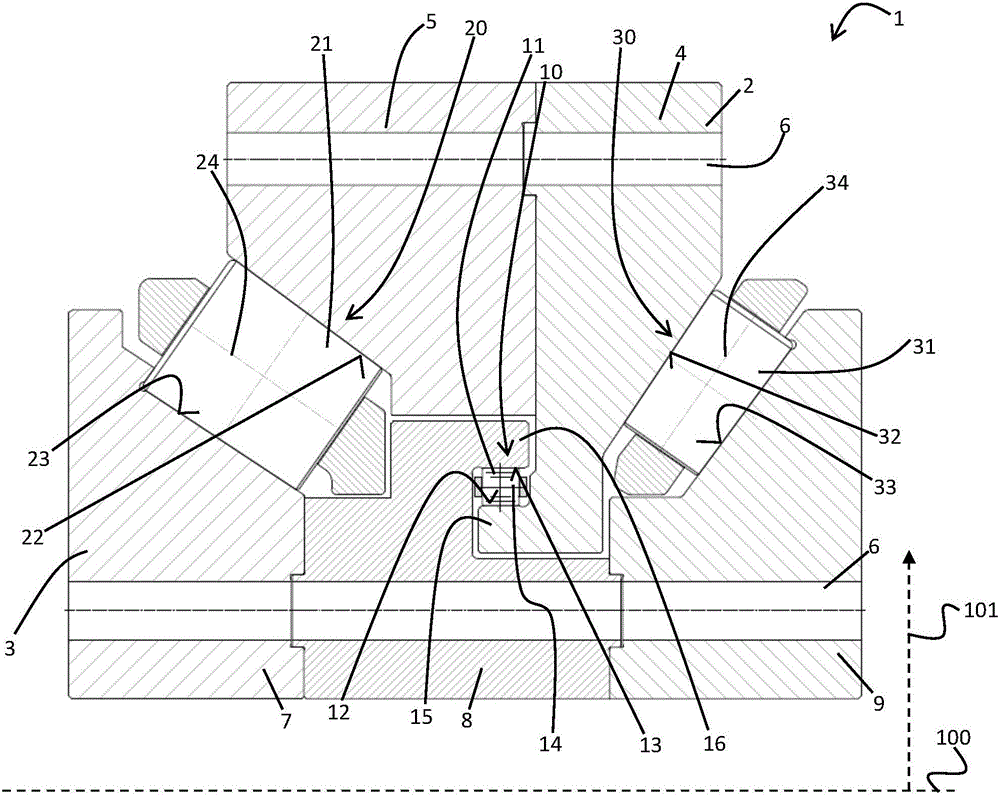

[0025] In the various figures, identical parts are always provided with the same reference numerals and are therefore usually also specified or mentioned only once in each case.

[0026] exist figure 1 , a schematic cross-sectional view of a roller bearing device 1 according to an exemplary first embodiment of the present invention is shown.

[0027] The roller bearing device 1 includes an outer ring 2 and an inner ring 3 . The inner ring 3 is mounted rotatably about an axis of rotation 100 relative to the outer ring 2 . The roller bearing arrangement 1 comprises three bearings: a smaller first bearing in the form of a first raceway 10 fitted with first rolling elements 11 and two substantially symmetrical larger bearings comprising The second raceway 20 fitted with the second rolling body 21 and the third raceway 30 fitted with the third rolling body 31 . The second and third raceways 20, 30 are formed in such a way that the inner ring 3 and the outer ring 2 support each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com