Linear actuator, hydraulic bearing, and motor vehicle with such a hydraulic bearing or linear actuator

A technology of linear actuators and engines, which is applied to supporting machines, reciprocating/oscillating/vibrating magnetic circuit components, shock absorbers, etc., and can solve problems such as undamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

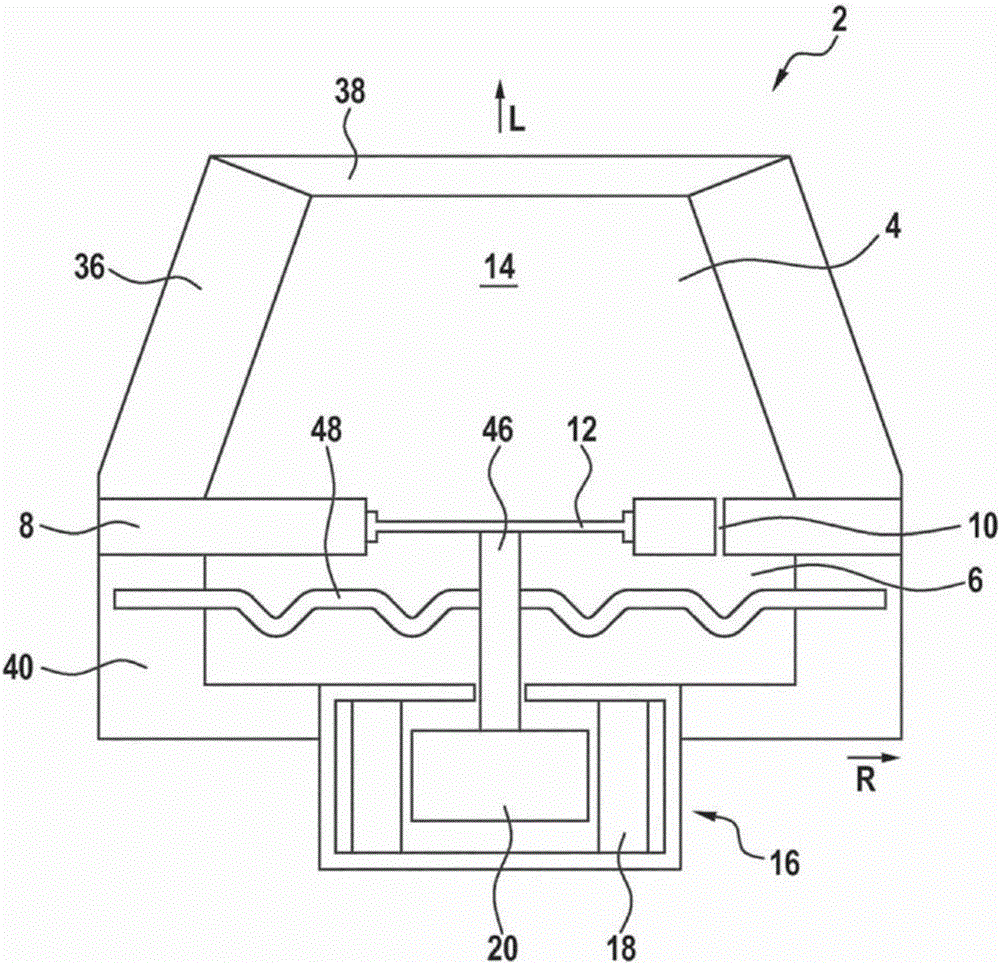

[0066] figure 1 A hydraulic mount 2 is shown. The hydraulic mount 2 comprises a load spring 36 in the form of a rubber element. The support spring 36 is conventionally in the form of a hollow body, the top side of the support spring 36 having a cover 38 . Attachment elements (not shown) for securing the engine are typically attached to the cover 38 . In a simple embodiment, the connecting element is a threaded bolt that can be screwed onto the engine. The underside carrying the spring 36 adjoins the partition 8 . The working chamber 4 is formed between the load spring 36 , the cover 38 , and the partition 8 . The working chamber 4 is filled with hydraulic fluid. This fluid is preferably a mixture of oil and water. Adjacently below the partition 8 in the longitudinal direction L is a hollow cylindrical base shell 40 , the inner space of which is divided by a flexible partition 48 . The space enclosed by the partition 8 , the partition body 48 and the base housing 40 form...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com