Steel plate perforating device with reset function

A technology of punching device and steel plate, applied in the field of construction, can solve the problems of steel plate cracking, operator injury, inconvenient alignment, etc., and achieve the effects of low cost, improved processing efficiency, and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

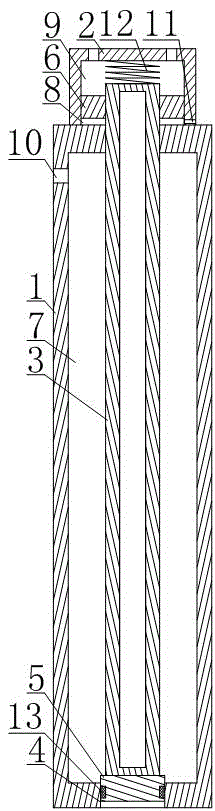

[0014] Such as figure 1 As shown, the steel plate punching device with reset function includes an air cylinder 1, a cover 2, a control rod 3, a sealing head 5, a piston 6 and a compression spring 12, wherein the control rod 3 of this embodiment is a hollow structure, and the present embodiment The upper and lower ends of the gas cylinder 1 of the example are all sealed, and the gas injection chamber 1 is formed in the gas cylinder 1. The gas injection port 10 is formed on the side wall of the gas cylinder 1, and the gas discharge port 4 is formed at the bottom of the gas cylinder 1. The gas discharge port 4 and the gas injection port 10 are all connected to each other. Gas injection cavity-7 is connected. The cover 2 of this embodiment is connected to the top of the gas cylinder 1 and forms an accommodating cavity with the gas cylinder 1. The piston 6 is arranged in the accommodating cavity and separates the accommodating cavity to form a gas-permeable cavity 9 above the pisto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com