Insect prevention corrugated board and manufacturing method thereof

A production method and technology of corrugated board, applied in the field of paper product manufacturing, can solve problems such as damage to internal items, easy generation of foam, user loss, etc., to achieve the effects of avoiding mosquito erosion, strengthening insect resistance, and increasing insect resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

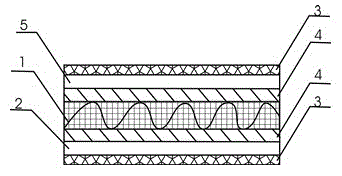

[0015] The invention provides an insect-proof corrugated board and a manufacturing method thereof, comprising a corrugated layer 1, a surface layer 2, an insect-proof layer 3, an adhesive layer 4, and an inner layer 5. The inner layer 5 is connected to the corrugated layer 1 through the adhesive layer 4, and the corrugated layer The other side of 1 is connected to the surface layer 2 through the adhesive layer 4, and the outside of the surface layer 2 and the inner layer 5 are respectively connected with an insect-proof layer 3. The gap formed by the corrugated layer 1 and the adhesive layer 4 is filled with a moisture-proof agent.

Embodiment 2

[0017] A method for making an insect-proof corrugated board, the specific steps of which are as follows: firstly add an insect-resistant agent and a chemical agent into the slurry, then mix and stir it, and after stirring, extrude the corrugated paper, the surface layer 2, and the inner layer through an extruder 5. The corrugated paper is used as the corrugated layer 1, and then the corrugated layer 1, the inner layer 5 and the surface layer 2 are bonded together by gluing. Insect repellents include oil of camphor, oil of wintergreen, and oil of eucalyptus. Chemical agents include defoamers, water repellents, retention aids, dry strength agents.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com