Liquid solid reaction process and device thereof

A liquid-solid reaction and process technology, applied in the direction of calcium/strontium/barium halide, calcium/strontium/barium chloride, etc., can solve the problems of slow reaction, uneven distribution of hydrochloric acid and limestone, incomplete reaction, etc. Uniform acid feeding, solving exhaust problems and gas collection problems, avoiding the effect of incomplete reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

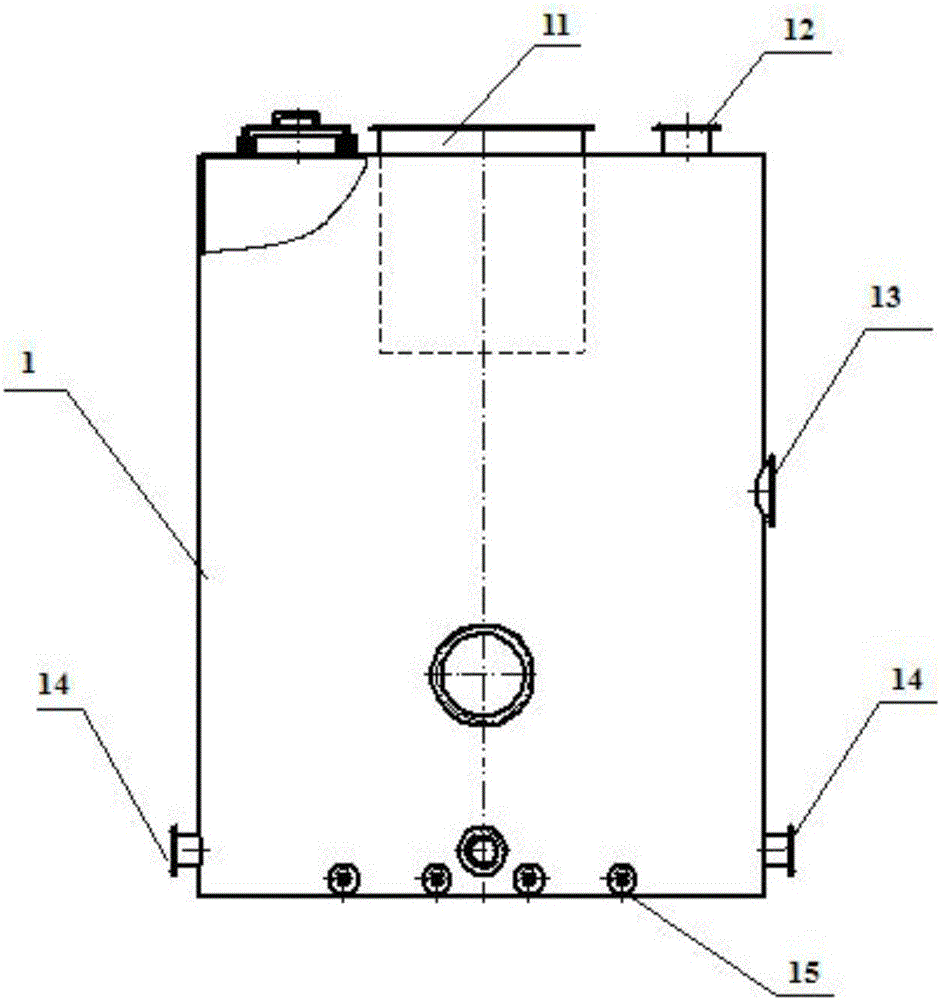

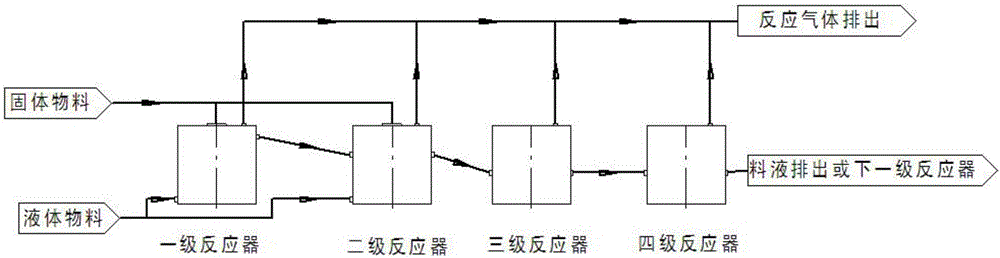

[0030] Such as figure 1 and image 3 Shown, a kind of liquid-solid reaction process, liquid material (such as hydrochloric acid) and solid material (such as limestone) are added in the primary reactor and carry out neutralization reaction, and limestone inlet 11 is arranged on the top of described reactor 1 , at least one acid inlet 15 is arranged at the bottom of the reactor 1, at least one exhaust outlet 12 is arranged at the top of the reactor 1, and the liquid outlet 13 and the sewage outlet 14 are arranged at both ends of the reactor 1 On the side, the reactor 1 is also provided with a maintenance port; a plurality of exhaust ports 12 arranged on the top of the reactor 1 are distributed in a circle; the limestone feed port 11 is fed by a feed pipe, And the gas collection holes are evenly arranged on the feed pipe.

Embodiment 2

[0032] Such as figure 1 and image 3 Shown, a kind of liquid-solid reaction technology, liquid material (such as hydrochloric acid) and solid material (such as limestone) are respectively added in primary reactor and secondary reactor and carry out neutralization reaction, and the structure of reactor is the same as embodiment 1. The reaction liquid produced by the primary reactor is connected to the secondary reactor through pipelines. Hydrochloric acid enters from the bottom of the secondary reactor, and limestone is added from the top of the secondary reactor. At the same time, the reaction liquid produced by the primary reactor enters the secondary reactor, so that the reaction liquid can continue to react in the secondary reactor, increasing The reaction time makes the acid-base neutralization reaction more fully.

Embodiment 3

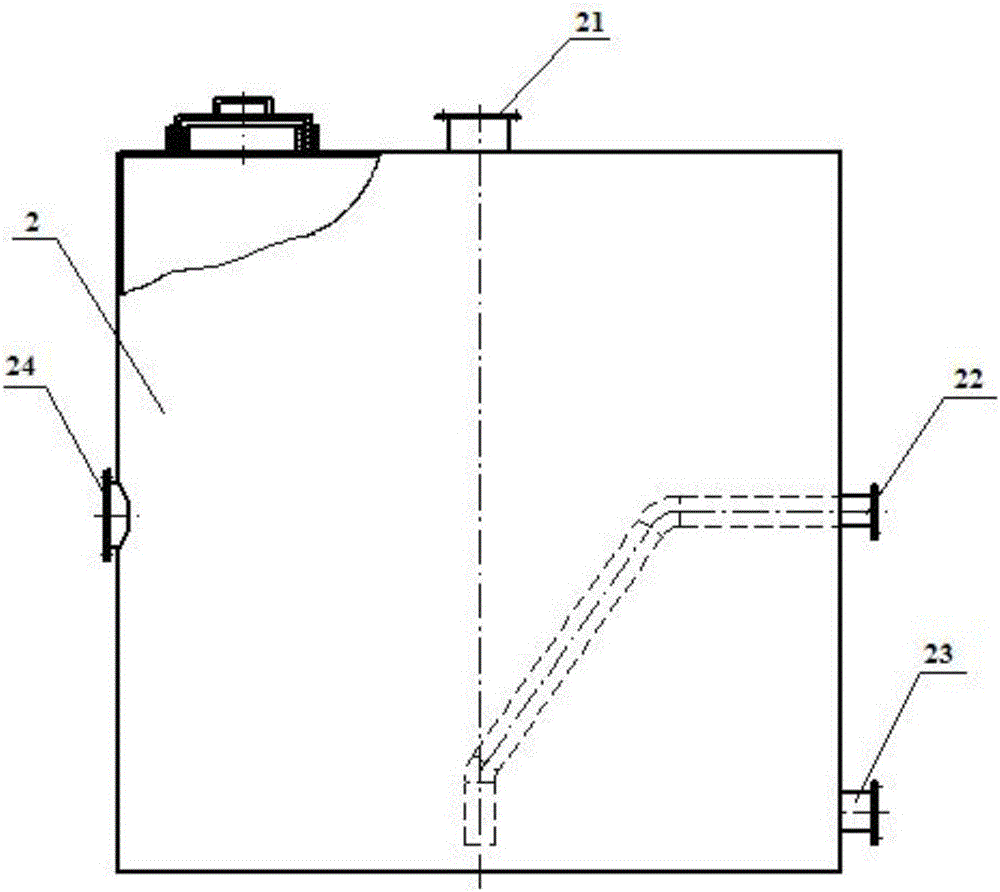

[0034] Such as figure 1 , figure 2 and image 3 Shown, a kind of liquid-solid reaction technology, liquid material (such as hydrochloric acid) and solid material (such as limestone) are respectively added in primary reactor 1 and secondary reactor to carry out neutralization reaction, the reaction that primary reactor produces The liquid enters the secondary reactor to continue the reaction, and the reaction liquid produced by the primary reactor and the secondary reactor enters the tertiary reactor 2 through the liquid inlet 24 to continue the reaction, and the top of the tertiary reactor 2 is provided with at least An exhaust port 21 , a liquid discharge port 22 and a sewage discharge port 23 are arranged on one side of the three-stage reactor 2 .

[0035] No new hydrochloric acid and limestone are added to the third-stage reactor, and the reaction liquid produced by the first two-stage reactor enters the third-stage reactor 2 to continue the reaction, increasing the reac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com