Structural heat-preservation integrated external wallboard, connecting structure and manufacturing method of structural heat-preservation integrated external wallboard

A technology for structural insulation and exterior wall panels, which is applied to building components, building structures, buildings, etc., can solve the problems of increased energy consumption loss of cold and heat bridges, poor thermal insulation effect, and large hidden dangers of installation, and achieves convenient construction and low cost. Low, the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

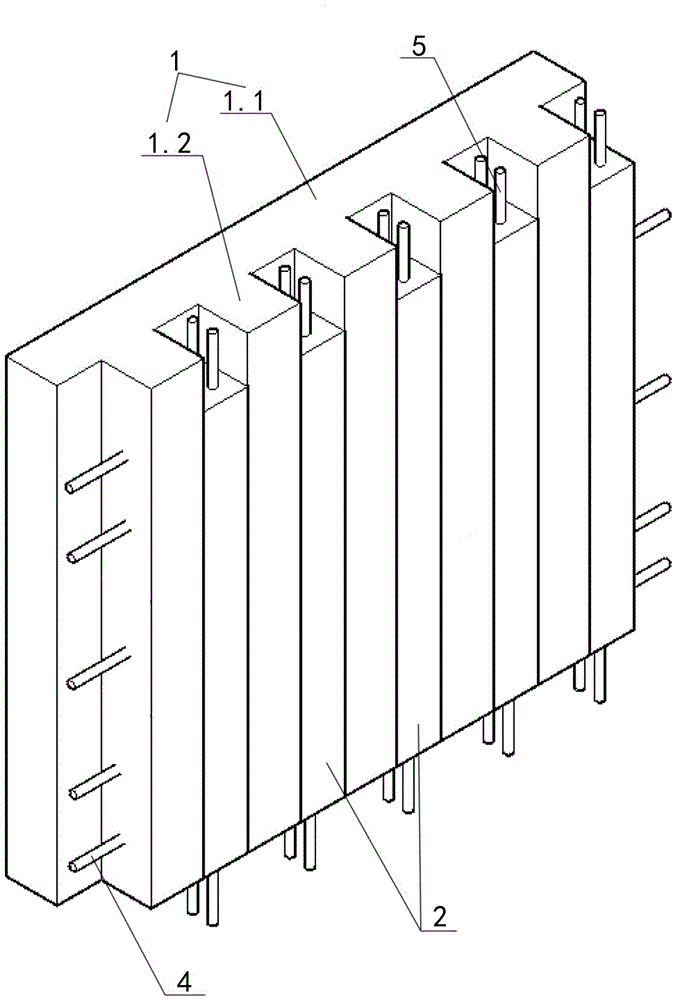

[0054] Embodiment one sees Figure 1-4 Shown:

[0055] An integrated exterior wall panel with structural insulation, comprising a panel body, the panel body is formed by layered pouring of a thermal insulation base layer 1 and a structural dense column layer 2, and the thermal insulation base layer 1 includes a flat base portion 1.1 and a convex The protruding rib 1.2 on one side of the surface of the base part is formed of a group of protruding ribs 1.21 that are long along the length direction of the base part 1.1 and arranged in parallel at intervals.

[0056] At least one horizontal connection through hole 3 transversely penetrating through the convex rib 1.2 is reserved at intervals along the length direction of the convex rib 1.2. Each connection through hole 3 is located at the same elevation position of the convex rib 1.21. Each connection through hole 3 are pierced with a horizontal connecting steel bar 4, the length of the horizontal connecting steel bar 4 is greate...

Embodiment 2

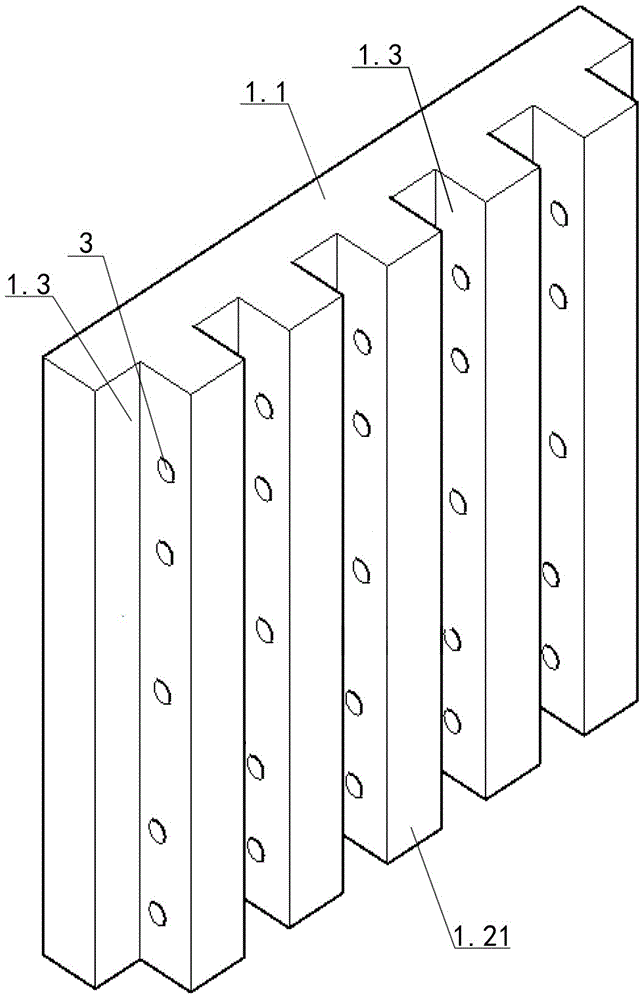

[0074] Embodiment two see Figure 5 As shown, the difference from Embodiment 1 is that in this implementation, the left side is a concave space 1.3, and the right side is also a concave space 1.3.

Embodiment 3

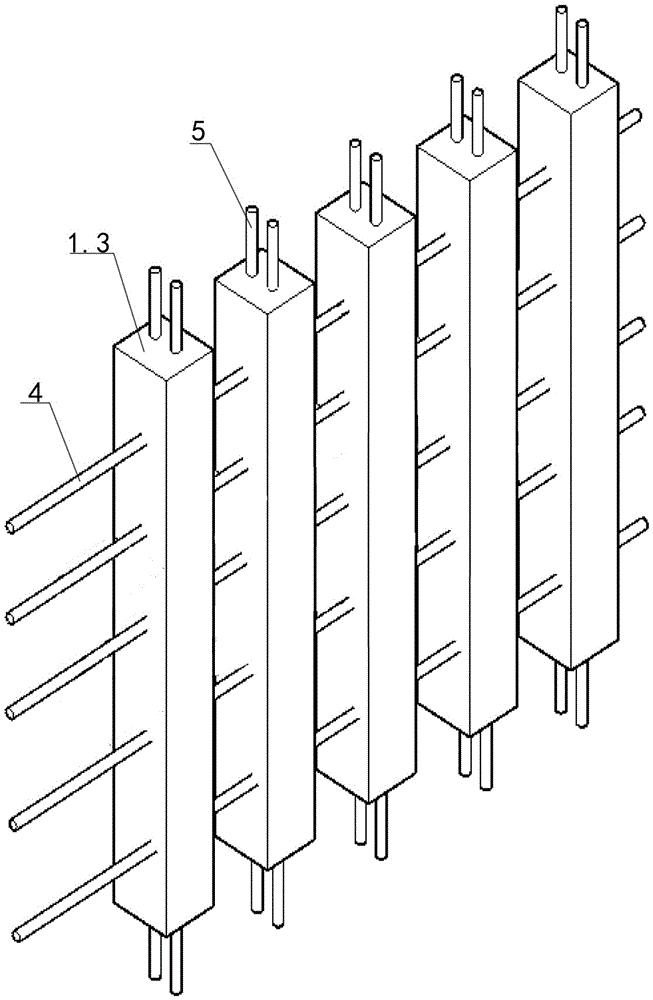

[0075] Embodiment three see Figure 6 As shown, the difference from the first embodiment is that in this implementation, the left side is a concave space 1.3, and the right side is a convex rib 1.21.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com