Construction method for repairing underground pipeline through non-excavation pipe expansion on original pipe position

A construction method and technology for underground pipelines, applied in the direction of pipes/pipe joints/fittings, pipeline laying and maintenance, mechanical equipment, etc. loss, the effect of achieving high efficiency and controllability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be described in further detail below in conjunction with the accompanying drawings and with reference to the data. It should be understood that the embodiments are only for illustrating the present invention and not limiting the scope of the present invention in any way.

[0031] Such as Figure 1-5 As shown, the invention discloses a construction method for repairing an underground pipeline without excavating a cracked pipe at the original pipe position, comprising the following steps:

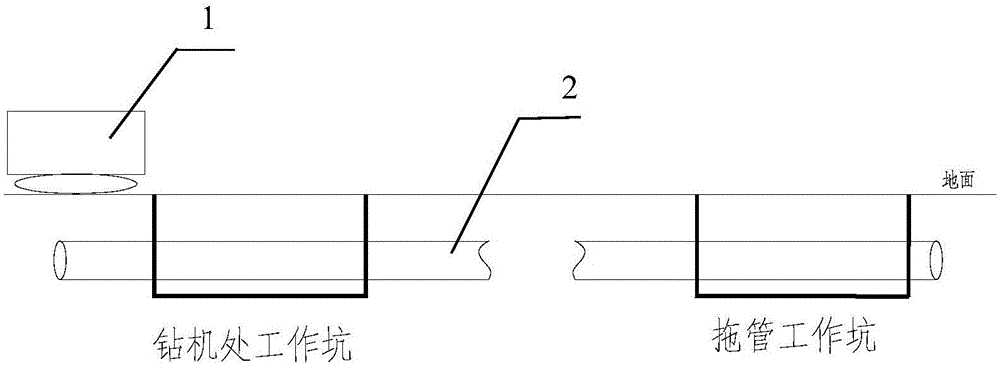

[0032] Step 1. According to the empirical distance, excavate the working pit at the drilling rig and the working pit for dragging the pipe along the length of the pipeline, such as figure 1 shown;

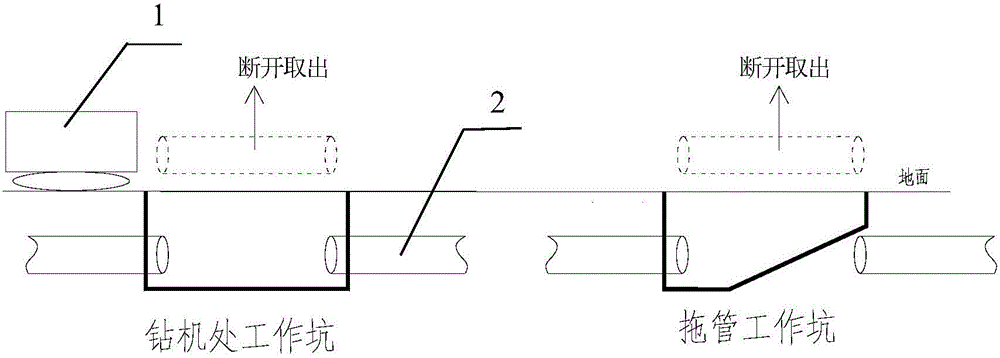

[0033] Step 2. Disconnect and take out the original pipes at the working pit at the excavation drilling rig and at the working pit for dragging pipes. figure 2 shown;

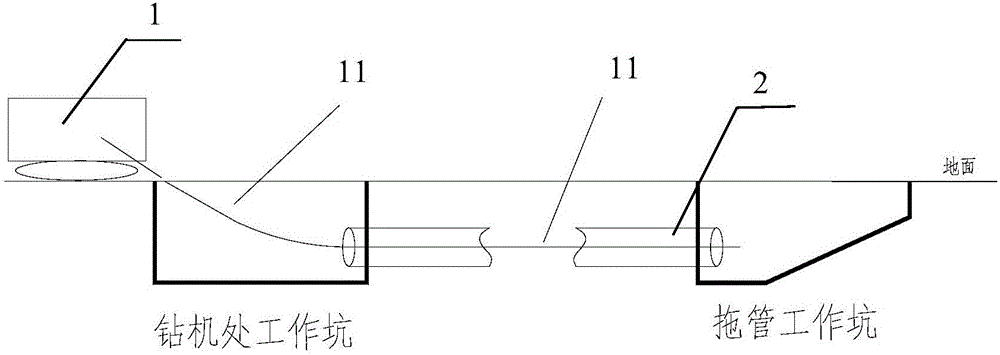

[0034] Step 3. Place the drilling rig on the guiding side of the working pit at the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com