Strengthened carat tube and manufacturing method thereof

A manufacturing method and carat tube technology, which are applied in the directions of hoses, pipes, rigid pipes, etc., can solve the problems of increased winding difficulty, weak rigidity and complex processing technology of single-wall corrugated pipes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

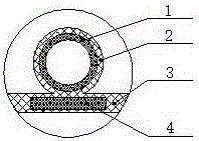

[0036] This embodiment provides a reinforced carat tube, which includes a PP single-wall corrugated tube 1 , a PE wrapping layer 2 , an inner layer 3 and a rigid material 4 . The PP single-wall corrugated pipe 1 is wrapped by the PE wrapping layer 2 to form a support pipe 8 , and the rigid material 4 is wrapped in the inner layer 3 . Wherein, the material of the rigid material 4 is PP, and the volume ratio of the rigid material 4 to the inner layer 3 is 25%.

[0037] This embodiment also provides a method for manufacturing a reinforced carat tube, comprising the following steps:

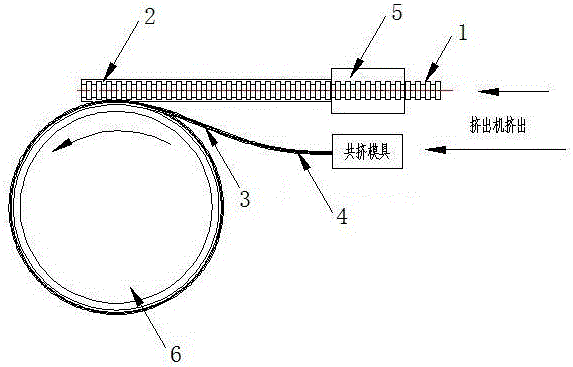

[0038] S1: Extrude PE sheet and PP sheet from two extruders respectively, and then co-extrude the PE sheet coated with PP through co-extrusion die coating, and then wind the PE sheet in hot state On the mold 6, the inner layer 3 of the carat tube is formed;

[0039] S2: The PP single-wall corrugated pipe 1 is obtained by prefabrication; the PP single-wall corrugated pipe 1 is transported to the coa...

Embodiment 2

[0044] This embodiment provides a reinforced carat tube, which includes a PE single-wall corrugated tube 1 , a PE wrapping layer 2 , an inner layer 3 and a rigid material 4 . The PP single-wall corrugated pipe 1 is wrapped by the PE wrapping layer 2 to form a support pipe 8 , and the rigid material 4 is wrapped in the inner layer 3 . Wherein, the material of the rigid material 4 is PA, and the volume ratio of the rigid material 4 to the inner layer 3 is 20%.

[0045] This embodiment also provides a method for manufacturing a reinforced carat tube, comprising the following steps:

[0046] S1: extrude PE sheet and PA sheet respectively by two extruders, and co-extrude PE sheet coated with PA after coating by co-extrusion die 5, and then heat the PE sheet Winding on the mold 6 to form the inner layer 3 of the carat tube;

[0047] S2: The PE single-wall corrugated pipe 1 is obtained by prefabrication; the PE single-wall corrugated pipe 1 is transported to the coating mold 5 thro...

Embodiment 3

[0052] This embodiment provides a reinforced carat tube, which includes a PP single-wall corrugated tube 1 , a PE wrapping layer 2 , an inner layer 3 and a rigid material 4 . The PP single-wall corrugated pipe 1 is wrapped by the PE wrapping layer 2 to form a support pipe 8 , and the rigid material 4 is wrapped in the inner layer 3 . Wherein, the material of the rigid material 4 is ABS, and the volume ratio of the rigid material 4 to the inner layer 3 is 15%.

[0053] This embodiment also provides a method for manufacturing a reinforced carat tube, comprising the following steps:

[0054] S1: PE sheet and ABS sheet are extruded by two extruders respectively, and PE sheet coated with ABS is obtained by co-extrusion after co-extrusion die coating, and then the PE sheet is hot-wound On the mold 6, the inner layer 3 of the carat tube is formed;

[0055] S2: The PP single-wall corrugated pipe 1 is obtained by prefabrication; the PP single-wall corrugated pipe 1 is transported to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com