Hot water circulation medium gas module furnace

A hot water circulation and modular furnace technology, applied in the field of boilers, can solve the problems of difficulty in controlling heat supply, affecting system work, and prone to safety accidents, and achieves the effects of eliminating potential safety hazards, compact size and energy saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and examples, and the contents of the examples are not intended to limit the protection scope of the present invention.

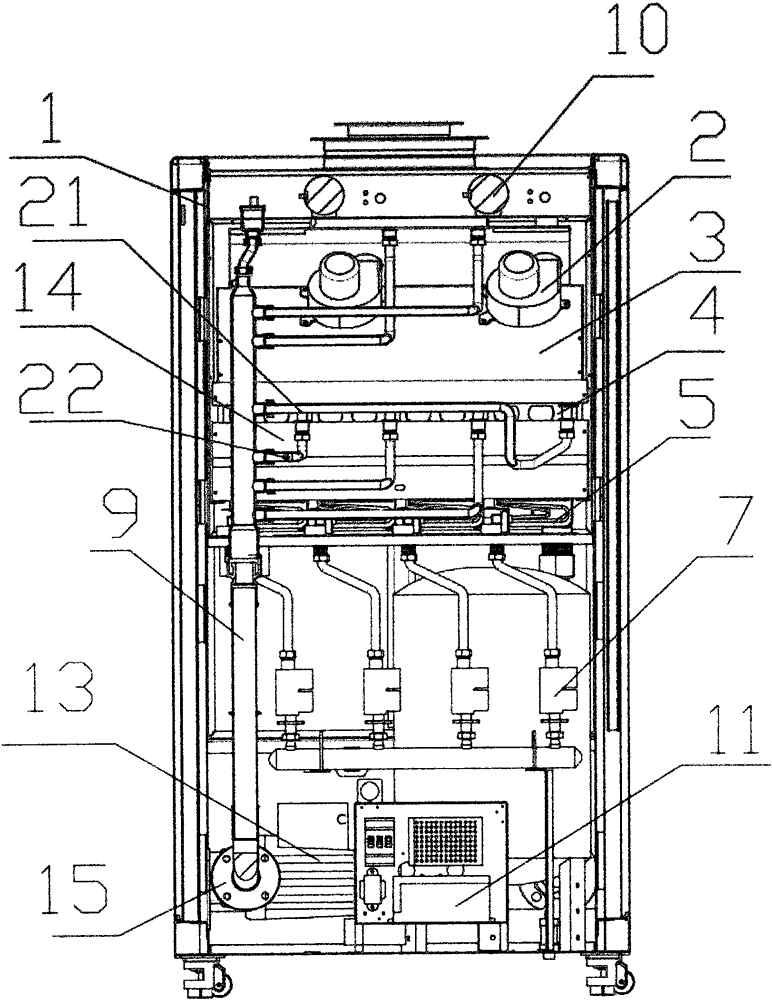

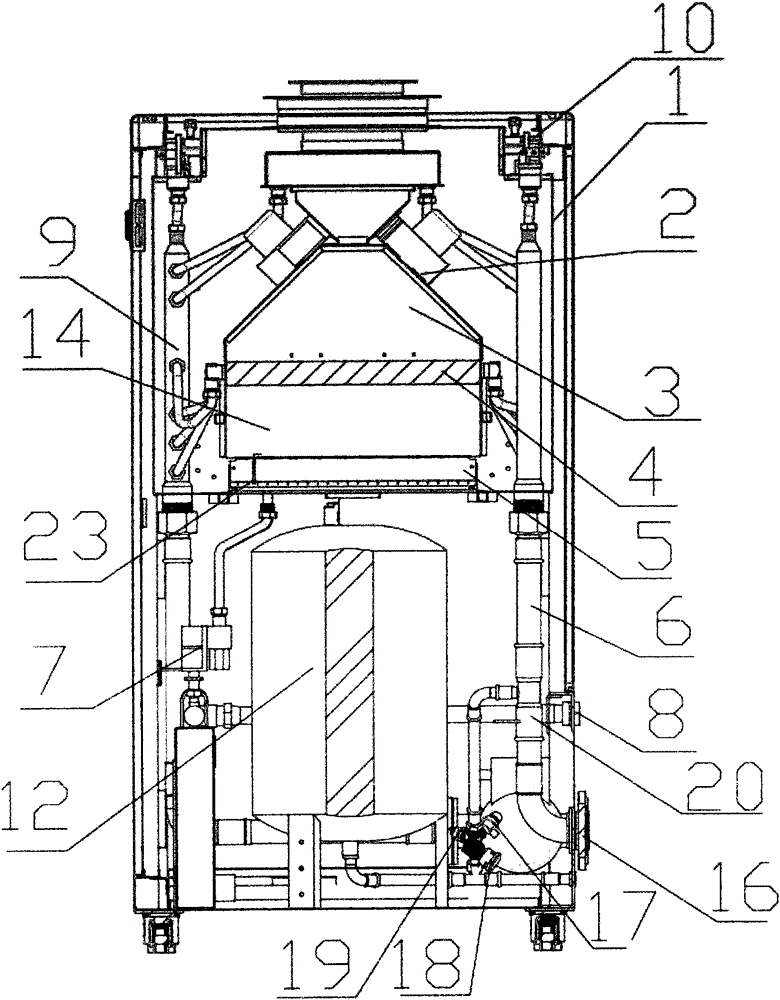

[0025] The invention relates to a hot water circulating medium gas modular furnace. refer to figure 1 with 2 , The hot water circulating medium gas modular furnace of the present invention includes a furnace body 1 . Preferably, the furnace body 1 is made of steel plate.

[0026] Wherein, multiple atmospheric burners 5 are horizontally arranged in parallel in the furnace body 1 . And above the atmospheric burner 5, a plurality of heat exchangers 4 are horizontally arranged in parallel. Preferably, one atmospheric burner 5 corresponds to one heat exchanger 4 . There is a certain space between the plurality of heat exchangers 4 and the plurality of atmospheric burners 5 , surrounded by enclosures to form a combustion chamber 14 . In this way, an at...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com