Robot scheduling method, device and computer readable storage medium

A scheduling method and robot technology, applied in the computer field, can solve problems such as low efficiency in picking up goods, and achieve the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

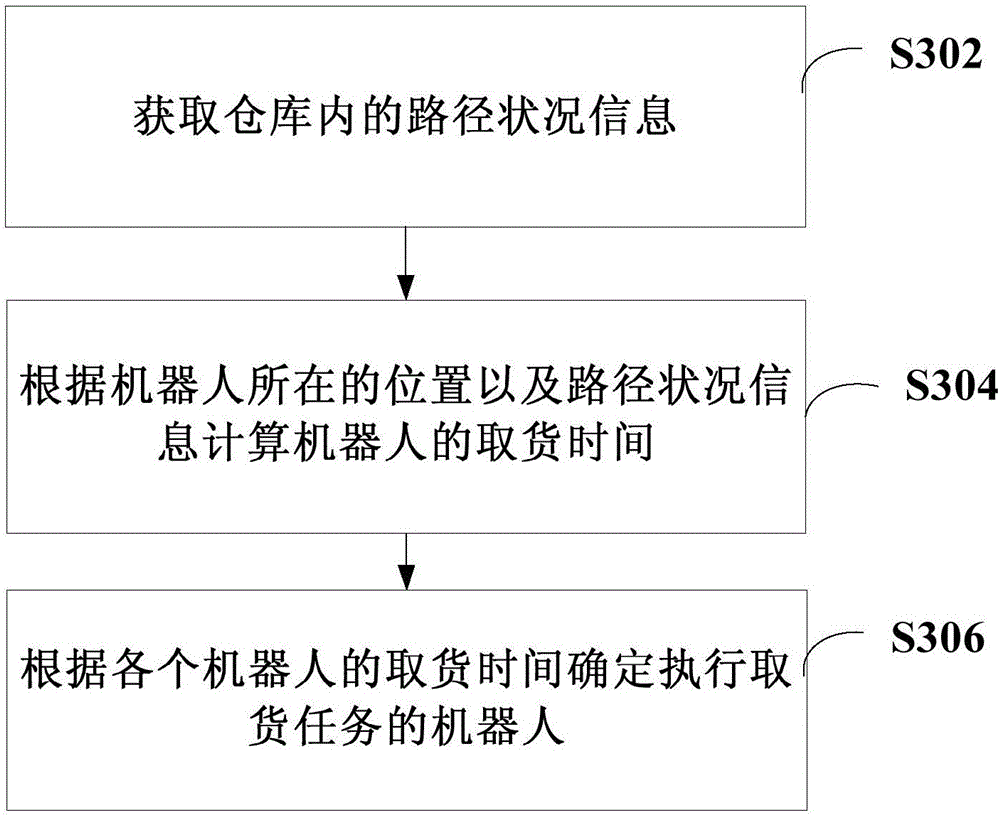

example 1

[0034] Example 1: Select the pick-up path of the robot based on the location of the robot and the path status information, and calculate the pick-up time of the robot based on the distance of the pick-up path and the walking speed of the robot. Specifically, when the route status information includes the direction of travel of the route, the route whose travel direction satisfies the accessibility of the pick-up location is selected as the pick-up route, for example, when considering the travel direction of some one-way roads, the robot cannot reach the pick-up location , then these one-way road segments are not selected as pickup routes. Alternatively, when the path status information includes path obstacle information, a pick-up path is selected from paths without obstacles. Alternatively, when the route condition information includes the congestion information of the route, the pick-up route is selected from the routes without the congestion condition. When selecting the p...

example 2

[0036] Example 2, according to the distance of each path for the robot to complete the picking task and the walking speed of the robot, calculate the basic picking time for the robot to pass through each path, and calculate the extra picking time for the robot to deal with path problems on each path according to the path status information; The total picking time of each path is obtained by adding the basic picking time and the extra picking time of the robot in each path, and the shortest total picking time is selected as the picking time of the robot. Specifically, plan the various possible paths for the robot to arrive at the pick-up location to pick up the goods and deliver the goods to the designated target location, and calculate the basic pick-up time for the robot walking on these paths. Some paths may appear Obstacle paths, such as dropped goods, or congested paths, take the time to deal with these path problems as the additional pick-up time, and finally get the total...

example 3

[0038] Example 3: Select the shortest path for the robot to complete the picking task, calculate the basic picking time for the robot to pass the shortest path according to the distance of the shortest path and the walking speed of the robot, and calculate the additional fetch time for the robot to handle the path problem on the shortest path according to the path status information The pick-up time is the pick-up time of the robot by adding the basic pick-up time and the extra pick-up time of the robot in the shortest path.

[0039] The method of the above-mentioned embodiment considers the extra pick-up time for processing the path problem, calculates the pick-up time of each robot on the shortest path, and then selects the robot that performs the pick-up task with the shortest pick-up time, thereby improving the pick-up efficiency.

[0040] In Example 2 and Example 3, the extra pick-up time is obtained, for example, by the following method: (1) When the path condition inform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com