Horizontal Architecture Processing for Integrated Circuit Devices

A technology of integrated circuits and processors, applied in electrical digital data processing, circuits, measuring devices, etc., can solve problems such as error prone, low quality, high order volume, etc., achieve the effect of fast and reliable labor, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

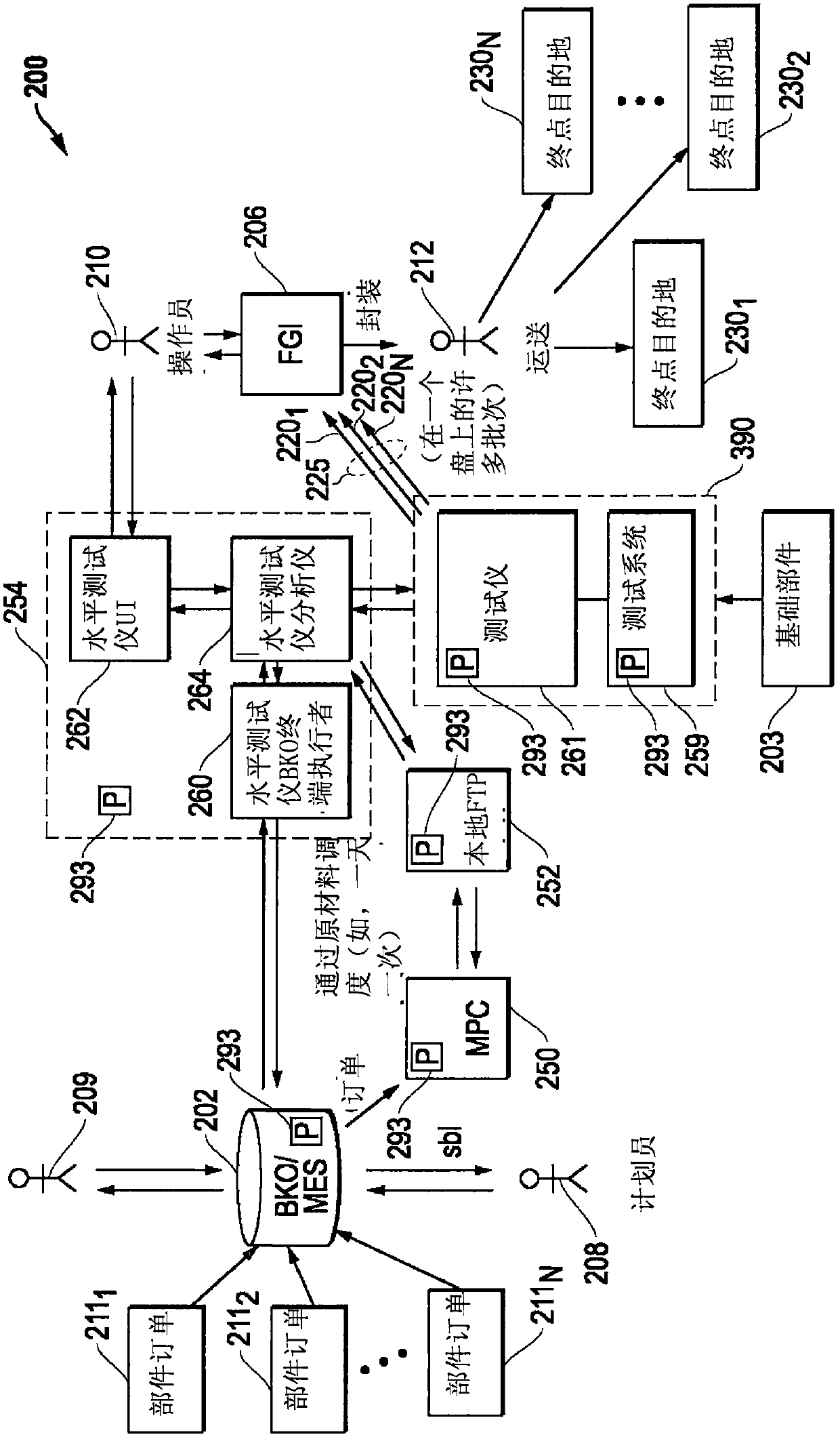

[0019] figure 2 An exemplary embodiment of an architecture 200 is described that can be used to simultaneously create and run multiple aggregated custom IC device part orders. In this embodiment, architecture 200 may be used for component testing and programming of a plurality of different types of custom horizontal integrated circuit (IC) device products from a plurality of incoming non-custom base IC device components 203 of a common type. An incoming non-custom base IC device part 203 may be previously assembled, assembled, and package tested (e.g., base part test), as image 3 shown in . As shown, multiple different individual custom IC device component orders 211 1 to 211 N Logic provided to the combined billing, order and manufacturing execution system (BKO / MES) 202 . For example, custom IC device component orders 211 may be received from one or more customers of an IC device product manufacturer. Each of the plurality of custom part orders 211 may specify a batch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com