High-voltage transmission line insulator umbrella protection cap

A high-voltage insulator, protective cap technology, applied in circuits, insulators, suspension/strain insulators, etc., can solve the problems of frequent line tripping accidents, the environment still does not work, the use effect is not satisfactory, etc., to reduce pollution, prolong The effect of service life and easy installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

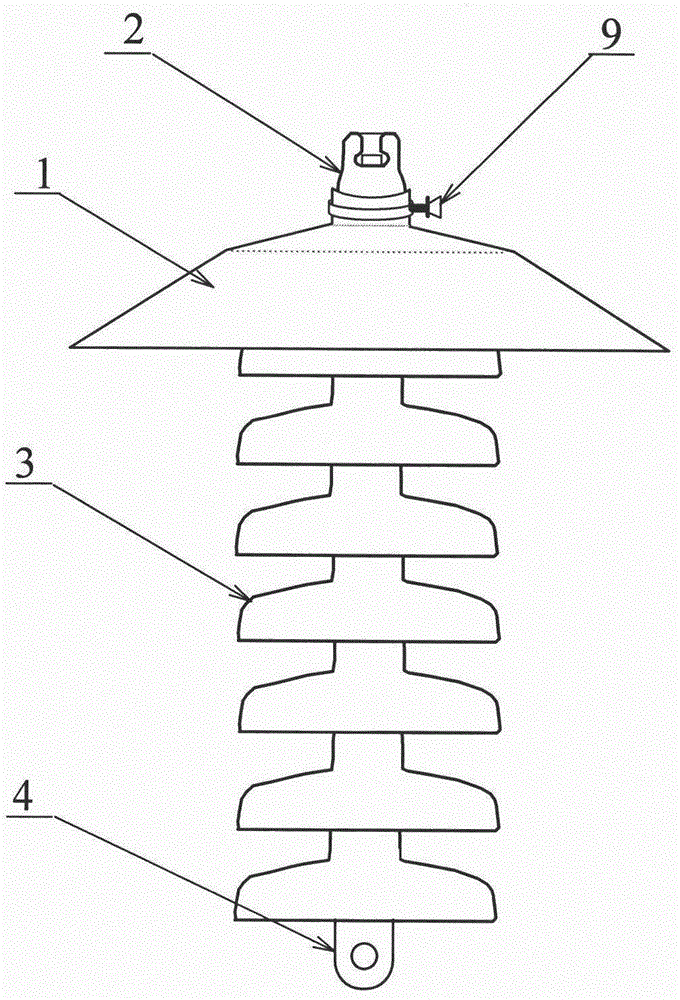

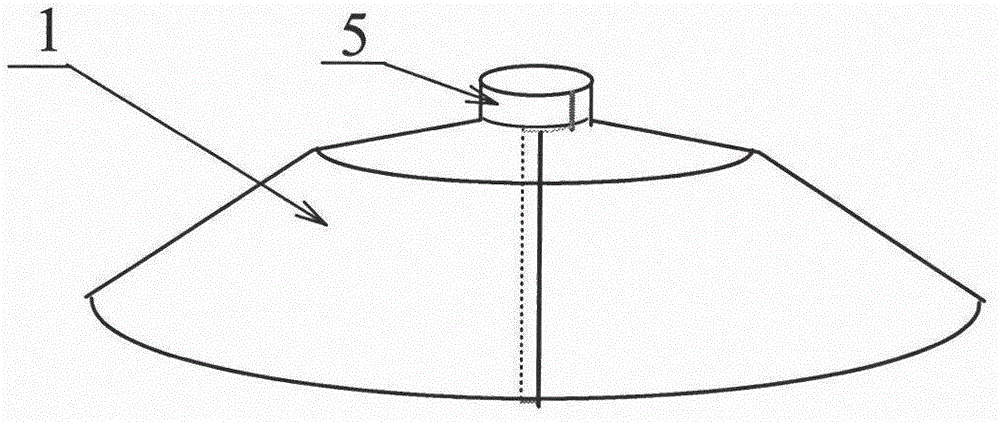

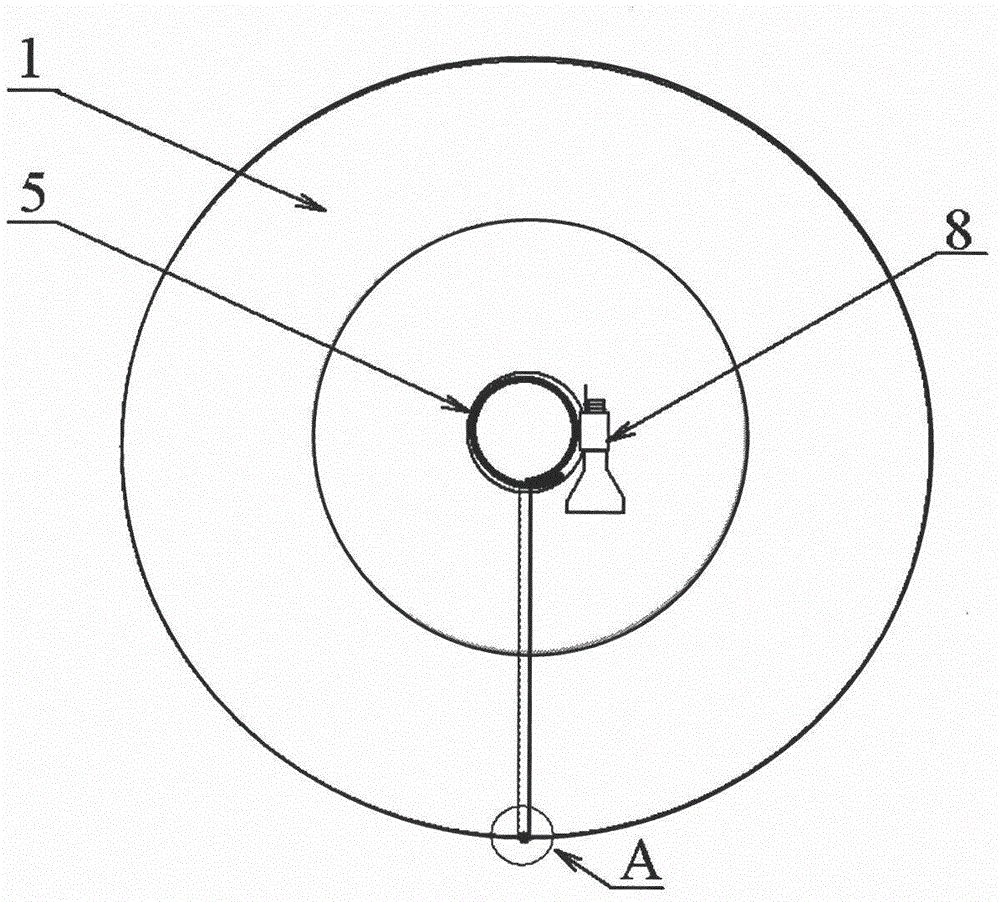

[0012] This patent includes in the drawings: the umbrella-shaped cap fixed end (5) is made from the upper part of the umbrella-shaped cap (1), and the umbrella-shaped cap (1) is in an open state, which is convenient to be fixed on the insulator iron cap (2). The upper lap of the opening of the cap (1) is made with umbrella-shaped cap lap joint protrusions (6), the lower lap of the opening is made with umbrella-shaped cap lap joint grooves (7), and the umbrella-shaped cap of the umbrella-shaped cap (1) The fixed end (5) is conveniently fixed on the insulator iron cap (2) by the fixed clip (8), and the umbrella-shaped cap overlapping protrusion (6) and the umbrella-shaped cap overlapping groove (7) are pressed together to form a Integral, the umbrella-shaped cap (1) is integrally molded by polymer silicone injection. After installation, because the diameter of the umbrella-shaped cap (1) is relatively large, even if there are birds excreting on it, the bird droppings will not fal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com