Winding type high-voltage battery

A high-voltage, winding-type technology, applied in secondary batteries, circuits, electrical components, etc., can solve problems such as affecting applications and increasing battery volume, avoiding pole fragmentation or powder drop, achieving large capacity, and overcoming stacking. the effect of winding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

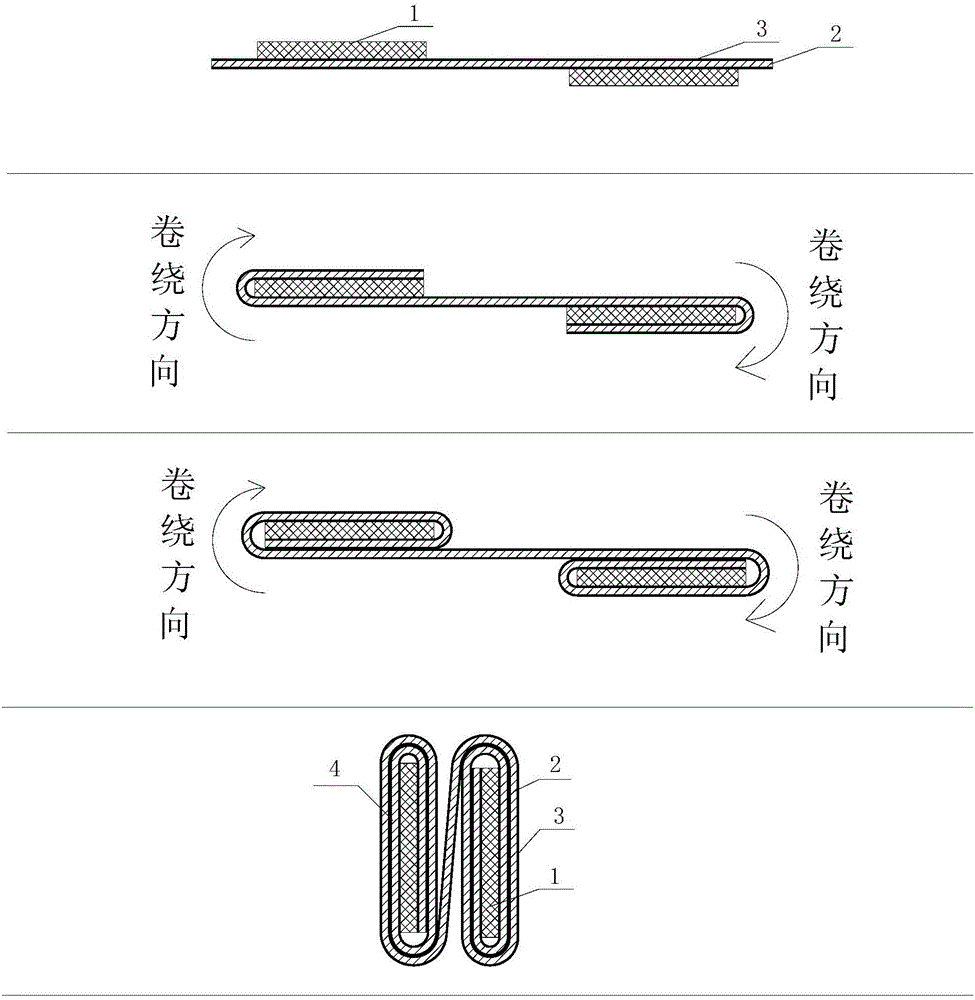

[0017] refer to figure 1 , a winding high-voltage battery of the present invention, including a winding plate 1, a pole piece 2, a separator 3 and a winding core 4, and the winding high-voltage battery is a superposition combination of two winding cores 4, and the winding core 4 includes a coiled plate 1 and a pole piece 2, the two ends of the pole piece 2 are respectively wrapped in the outer circumference of the two coiled plates 1 in a reverse spiral shape, and the outer wall of the pole piece 2 is covered with a diaphragm 3. The winding method of the winding core 4 is as follows: the winding plate 1 winds several turns in reverse around the two ends of the pole piece 2 until the end faces of the two winding cores 4 on different sides are attached to both sides of the same section of the pole piece 2 , the winding numbers of the two winding cores 4 are the same. The two ends of the pole piece 2 are flush with the ends of the coiled plate 1 . The cross-section of the folde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com