Dedicated large-sized saucepan for mess with dishes cooked in large pot at one time and operating method of dedicated large-sized saucepan

A technology of cauldron dishes and canteens, which is applied in the field of kitchen utensils, can solve the problems of discounted taste of cauldron dishes, difficulty in controlling the amount of condiments, and uneven mixing, so as to reduce the labor intensity of chefs, improve the taste and stirring effect of cauldron dishes Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

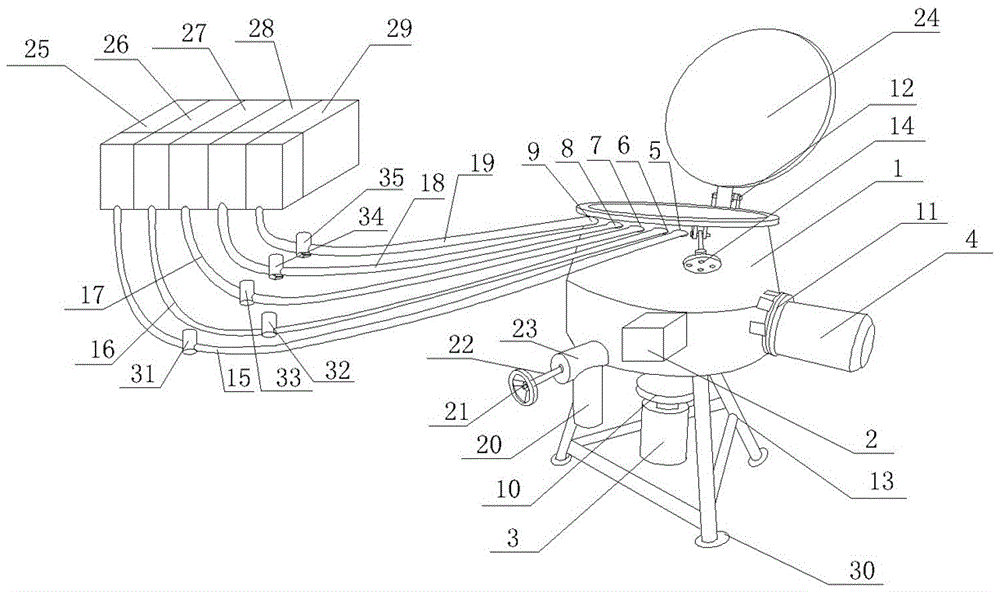

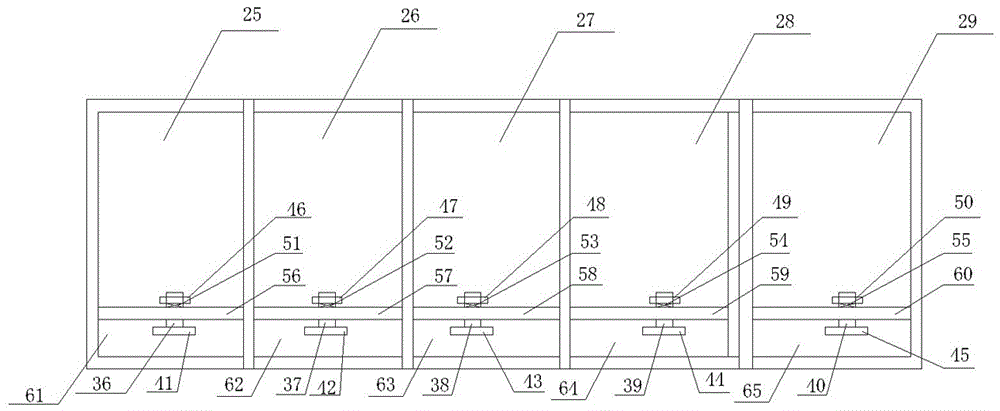

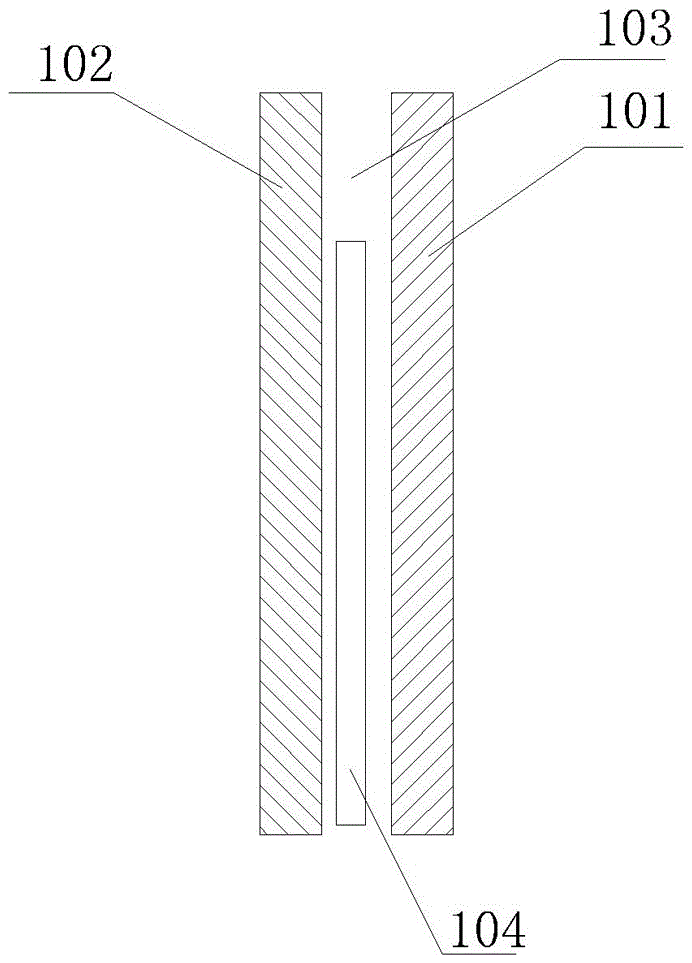

[0038] Such as Figure 1-3As shown, a large cooking pot dedicated to a big pot vegetable canteen includes a pot body 1, a bracket 13, a first stirring motor 3 arranged at the bottom of the pot body 1, a first stirring shaft connected to the first stirring motor 3, and a first stirring The blades, the top cover 24 arranged on the top of the pot body 1 , the electric control box 2 and the heating device arranged on the pot body 1 . The pot body 1 top is provided with several condiment inlets, and the condiment imports are connected to the condiment storage tanks through condiment pipelines. One side of the pot body 1 is provided with a second stirring motor 4 for vertical stirring, a second stirring shaft and a second stirring blade. The second stirring blade is located on the inne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com