Method for manufacturing sporting protection appliances and sporting protection appliances manufactured by using method

A technology for protective equipment and a manufacturing method, which is applied to the manufacture of protective equipment for sports and the field of sewing accommodation bags or shells, can solve the problems of affecting the effect of activities, time-consuming and laborious, and inefficient manufacturing of manual sewing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to enable your review committee members to clearly understand the content of the present invention, only the following descriptions are used together with the drawings, please refer to them.

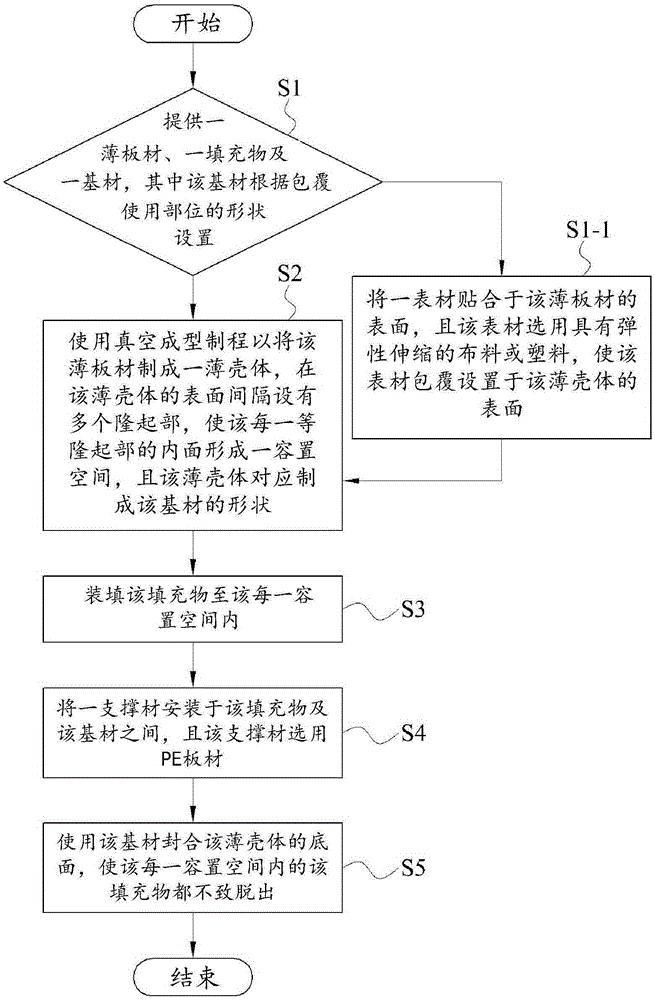

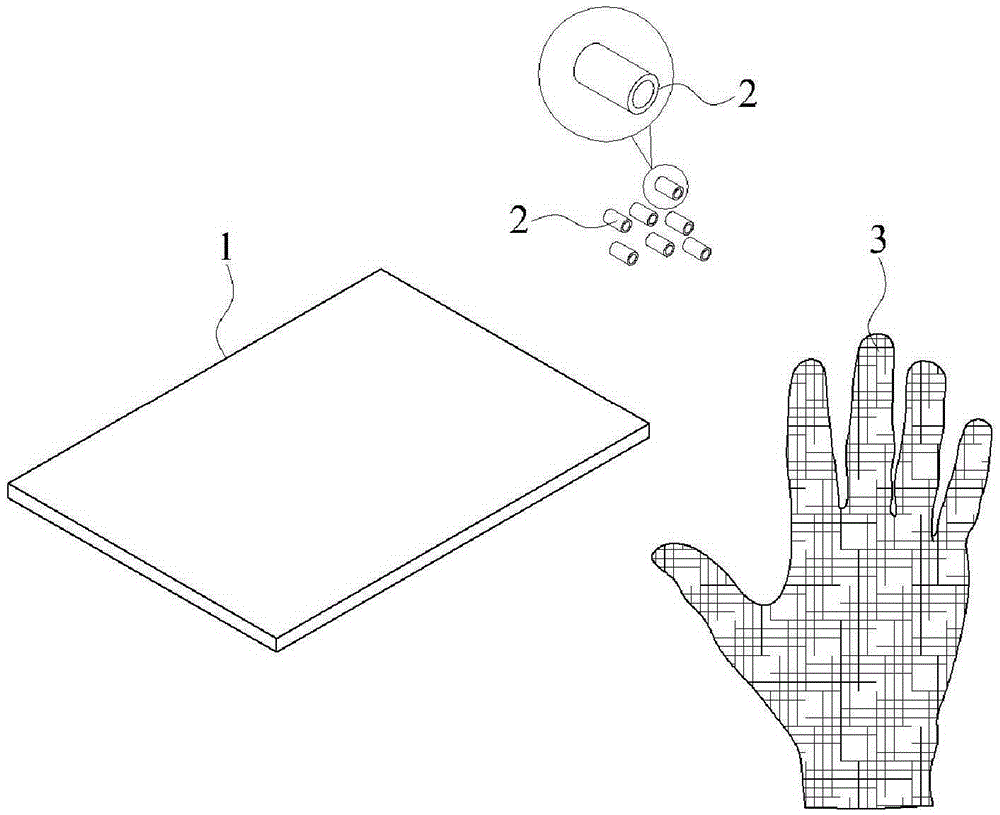

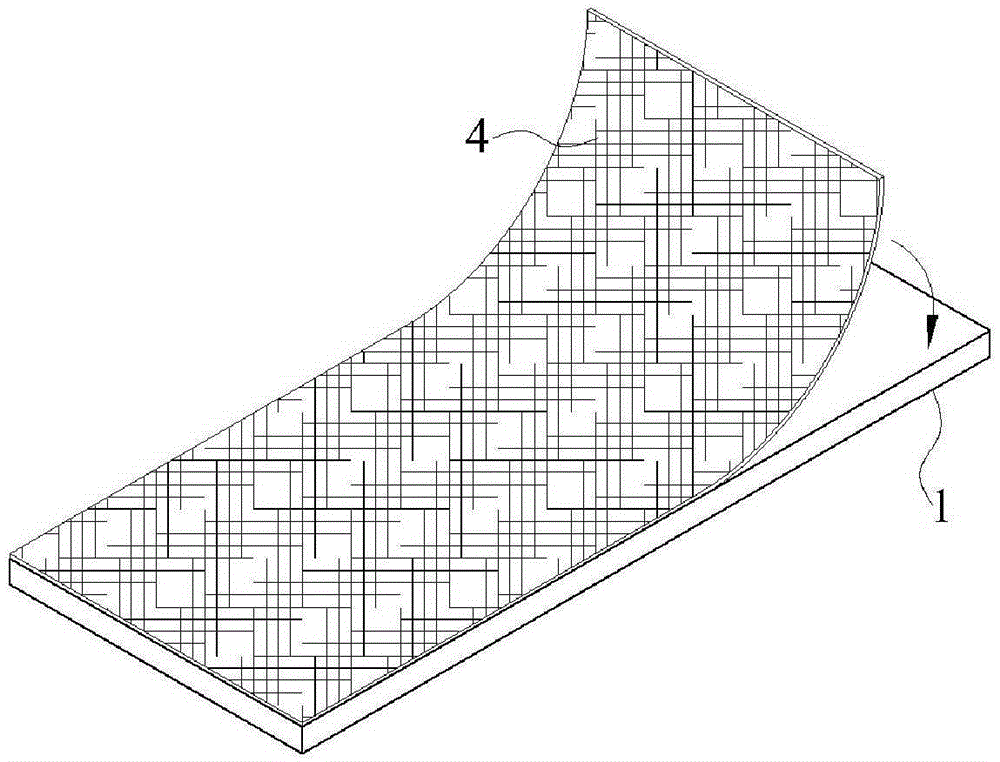

[0028] see figure 1 and 2 ˜7 are respectively the flow chart of the steps of the preferred embodiment of the present invention and the state diagrams corresponding to each step. As shown in the figure, a manufacturing method of a sports protective article of the present invention comprises the following steps:

[0029] S1: Provide a thin plate 1, a filler 2 and a base material 3, wherein the base material 1 is arranged according to the shape of the part to be covered. It should be noted that the sheet material 1 selected in the present invention is selected from one of thermoplastic polyurethane elastomer rubber (TPU, Thermoplastic polyurethanes) and polyvinyl chloride (PVC, Polyvinylchloride), which itself has good elasticity , flexibility and ductility, and can be ea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com