Aluminum electrolysis cathode carbon block phosphorous pig iron casting unit and method

A technology of phosphorus pig iron casting and cathode carbon block, which is applied in the field of aluminum electrolytic cells, can solve the problems of carbon block cracking, low pass rate, easy cracking in casting, etc., and achieve the effect of reducing power cost, prolonging service life, and stable start and stop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

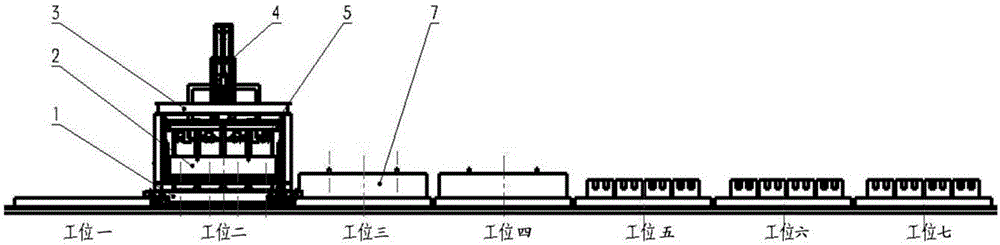

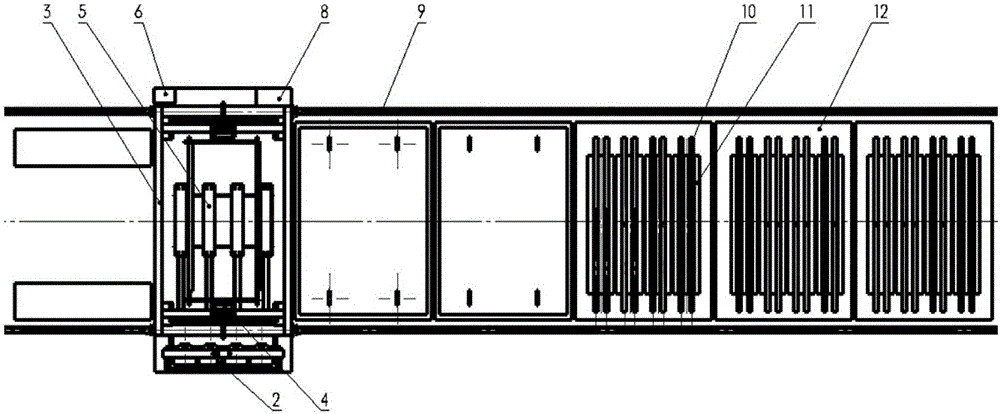

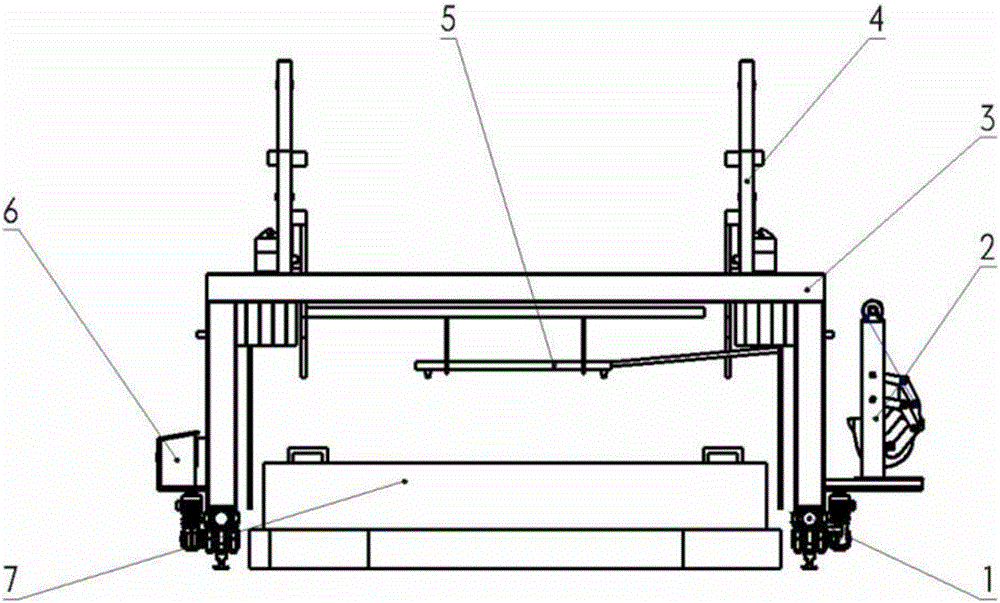

[0022] Such as Figure 1-Figure 4 As shown, the phosphorus pig iron casting unit of the present invention is composed of a mobile vehicle 1, a ladle system 2, a gantry system 3, a lifting mechanism 4, a gate distribution system 5, a control cabinet 6, a heating cover 7, a hydraulic station 8, and a rail 9. It is composed of cathode steel rod 10, cathode carbon block 11, workbench 12 and other components.

[0023] All the power of the whole system is provided by the hydraulic station 8. Four cathode carbon blocks 11 are placed in one heating mantle 7, and one cathode carbon block 11 requires four cathode steel rods 10 to assemble, and each cathode steel rod 10 corresponds to a gate.

[0024] The gate splitting system 5 has four groups, and each group has four gates, which just correspond to the cathode steel bars 10 . The gate splitting syst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com