Method for processing precision part by rotating horizontal jig boring machine for 180 degrees

A technology of coordinate boring machine and precision parts, which is applied in the field of horizontal coordinate boring machine rotating 180° to process precision parts, can solve the problems affecting the machining accuracy of parts, machining error, programming center positioning error, etc., to improve machining accuracy and widely popularize and apply value. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Embodiments of the present invention are described in detail below, and the embodiments are exemplary and intended to explain the present invention, but should not be construed as limiting the present invention.

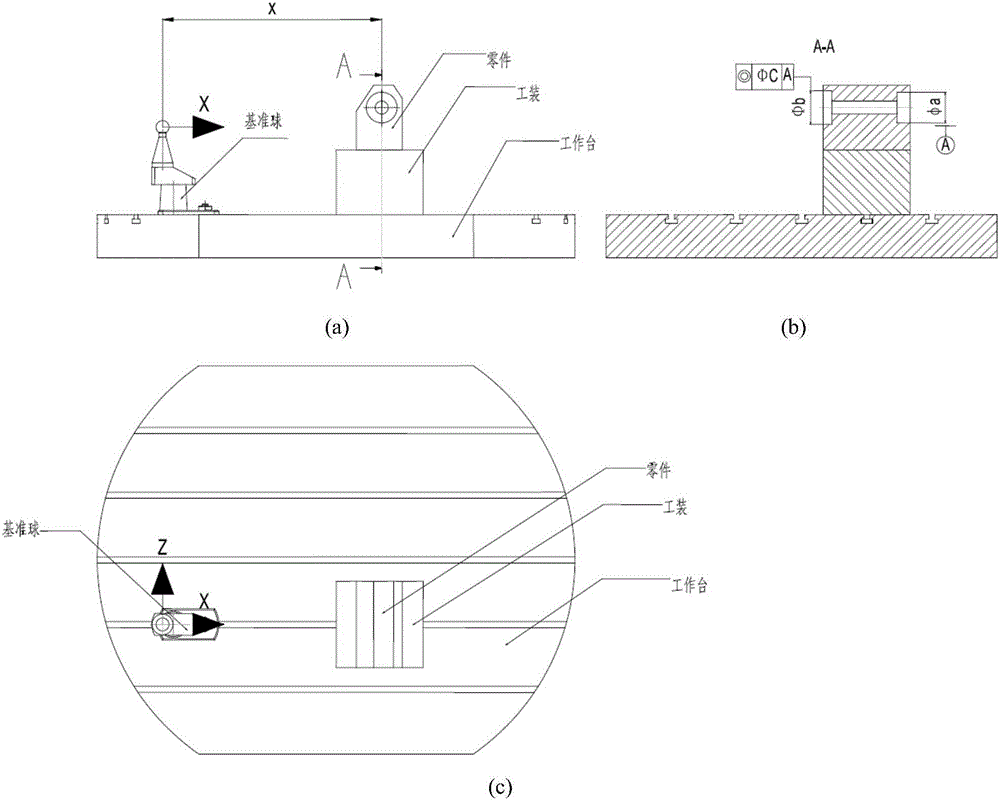

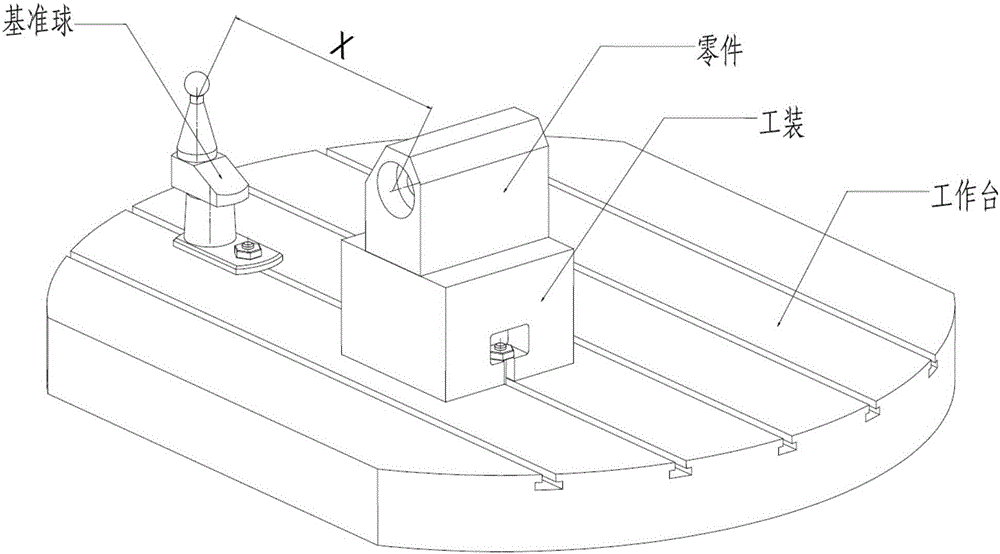

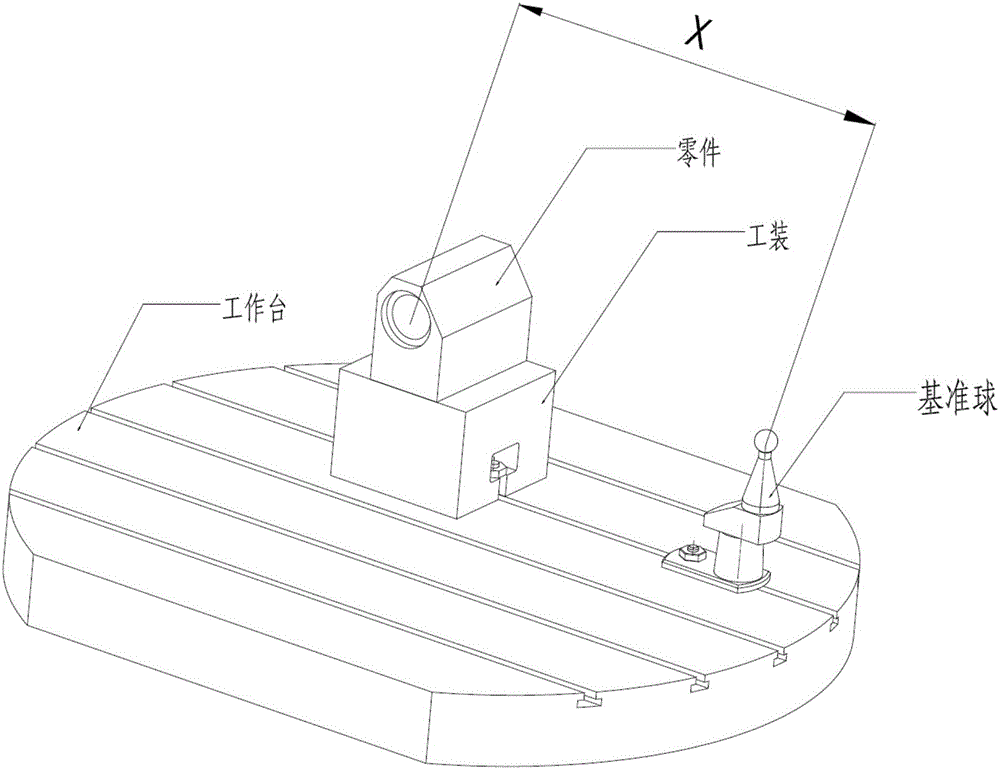

[0022] The invention uses the principle that the distance between the reference ball and the reference of the part remains unchanged before and after the workbench rotates 180° to process the feature of the part. The parts suitable for processing in the present invention should have the following characteristics: ① The worktable needs to be rotated 180° for processing; ② The position accuracy such as coaxiality and position degree needs to be guaranteed to be high.

[0023] During processing, firstly, the table of the horizontal coordinate boring machine is at the 0° position, and the tooling, parts and reference ball are clamped. The reference ball uses a reference ball for high-precision positioning. The X-axis is perpendicular to the plane of the worktable....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com