Device and method for automatic grinding and polishing of illumination optical fibers and cables

A fiber optic cable and automatic technology, applied in the field of mechanical processing, can solve problems such as difficult fixation, unstable pressure, and unstable motion trajectory, and achieve the effects of simple processing, improved production efficiency, and avoiding unstable pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

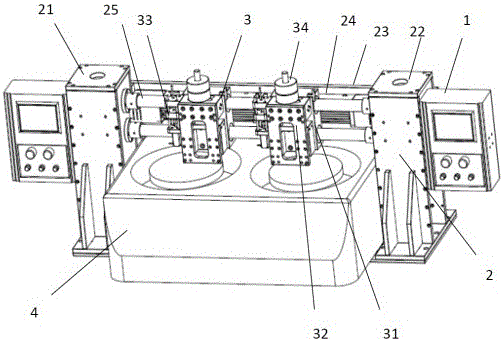

Embodiment 1

[0019] Example 1: The product to be ground and polished is a medical light guide optical fiber bundle, which is bound together by thousands of optical fibers with a diameter of tens of microns to form a guide beam with a diameter of 5 mm. The end face of the guide beam to be ground and polished is made of optical fiber, glue and Composed of stainless steel, the grinding and polishing machine (4) drives a grinding and polishing tool with a diameter of 200mm. The grinding and polishing auxiliary materials are diamond sandpaper with a specific particle size and grinding liquid. The grain size of the sand paper is 15 μm and 1 μm respectively. Grinding and polishing machine (4) drives a grinding and polishing tool with a diameter of 200 mm and 15 μm diamond sandpaper with pure water at a speed of 100 rpm / min for 2 minutes to grind the end face to be ground until the optical fiber, glue and stainless steel are on the same end face, and the end face is smooth and polished. The machine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com