Thread twisting disk

A technology of threaded discs and twisted discs, applied in the field of threaded twisted discs, can solve the problems of inconvenient tool replacement, failure of ordinary wrenches, inconvenient use and carrying, etc., and achieve the effect of easy disassembly, convenient carrying and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with specific embodiments, which are explanations of the present invention rather than limitations.

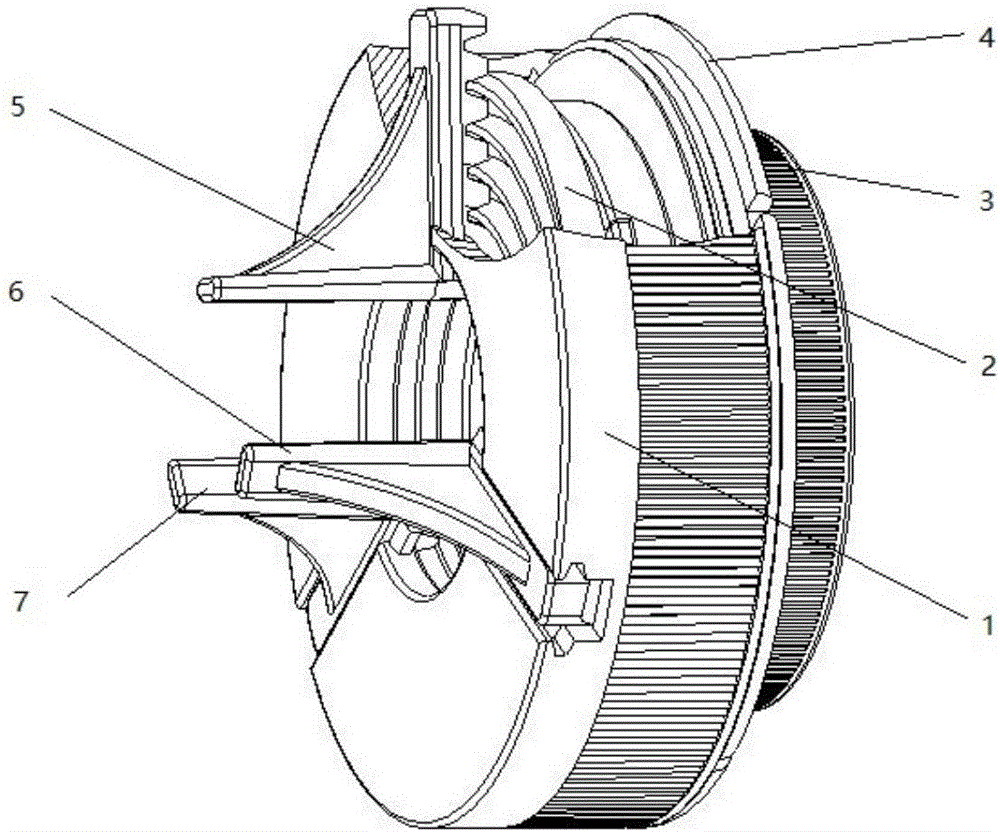

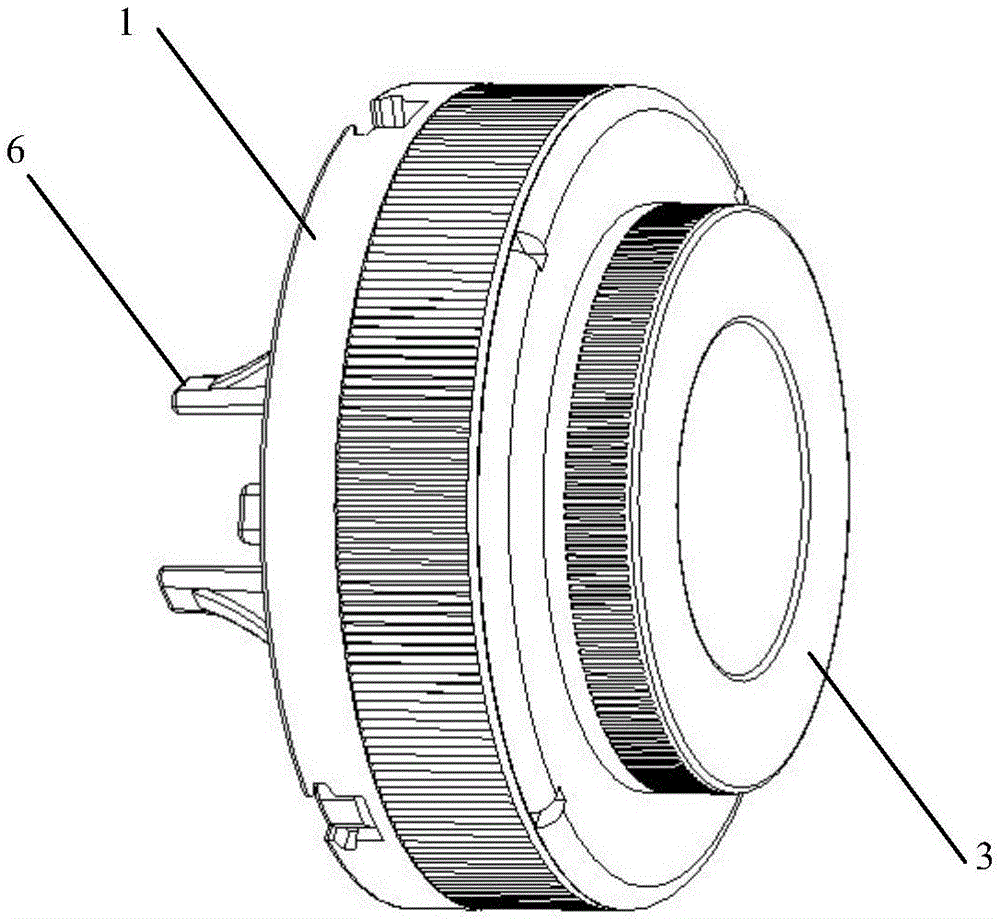

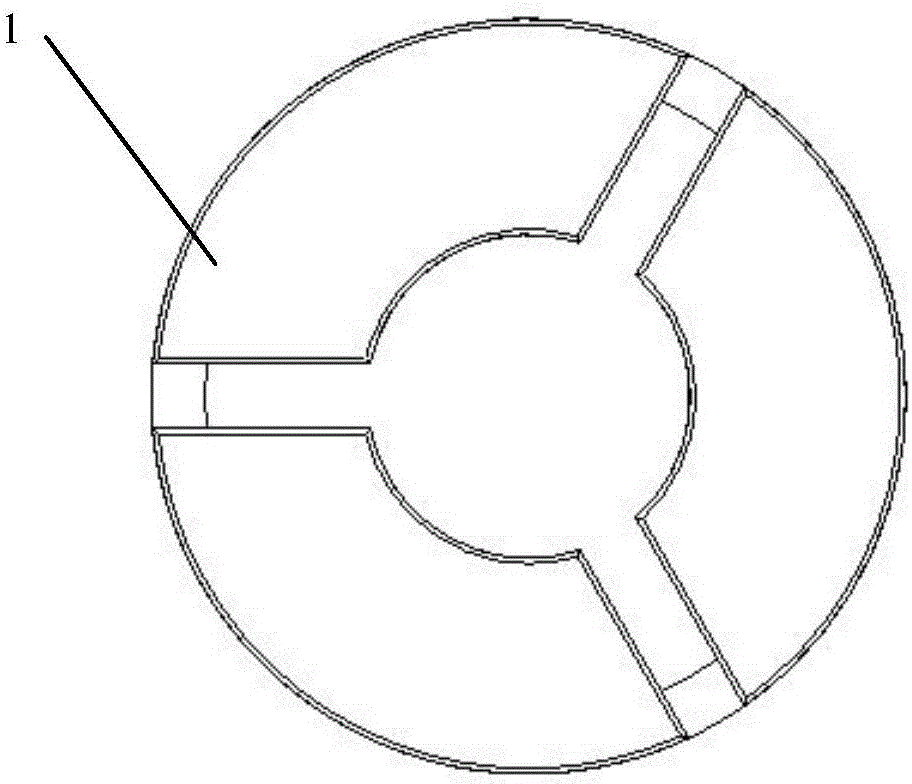

[0027] see Figure 1 to Figure 7 , a threaded torsion disk, including a threaded disk 2 located between the shell 1 and the end cover 4, the front end of the threaded disk 2 is provided with a helix, and the back is provided with a fan-shaped boss; the front surface of the shell 1 is provided with a radial direction Radial notches, the claws pass through the notches on the shell 1, and the fixed teeth at the end of the claws are nested between the helixes of the threaded disc 2; the front end of the adjustment knob 3 passes through the matching sector boss and the threaded disc 2 The back faces are fitted together, and the rear end surface of the adjustment knob 3 protrudes from the end cover 4 .

[0028] The diameter of the fan-shaped boss on the back of the threaded disk 2 is larger than t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com