Intelligent assembly line for cleaning garbage cans

A garbage can and assembly line technology, applied in the field of sanitation, can solve the problems of limited cleaning volume, pollution of garbage cans, limited processing efficiency, etc., and achieve the effect of simple and comprehensive cleaning process, saving mechanical structure, and simple and reasonable configuration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

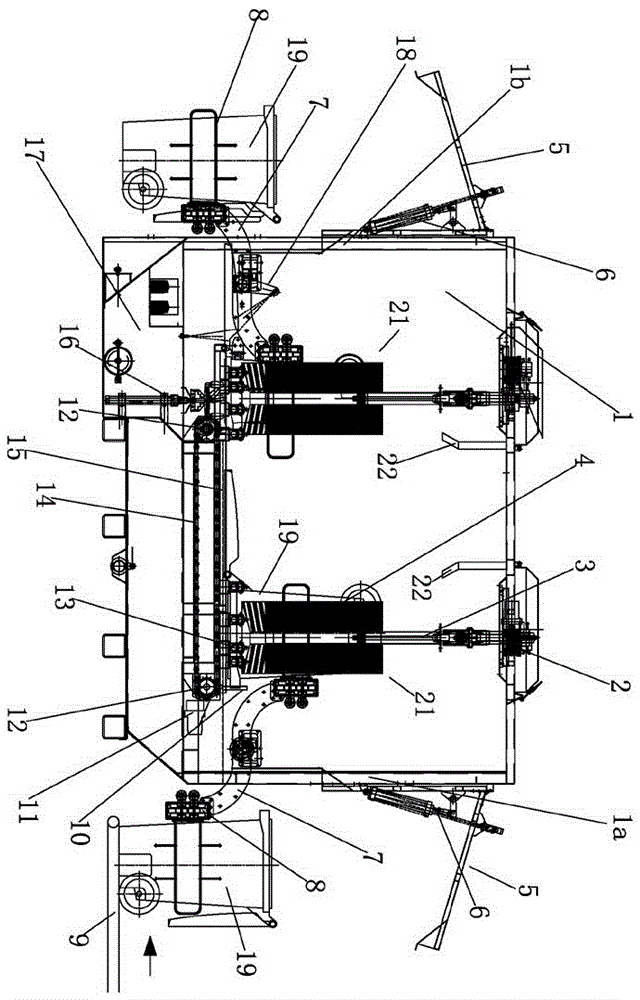

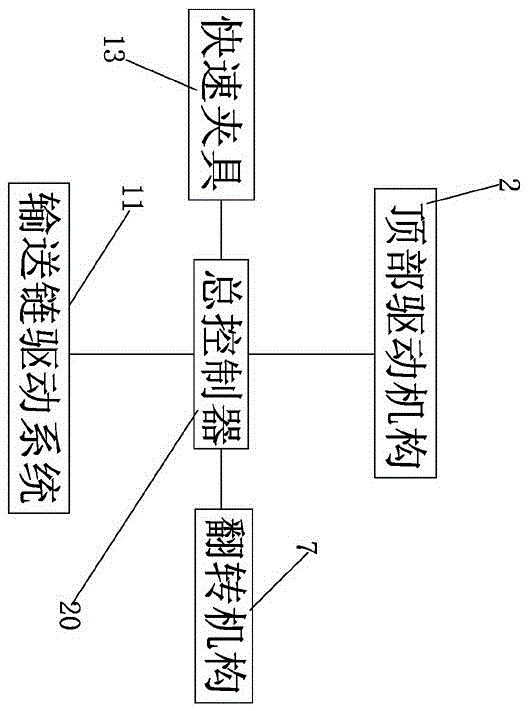

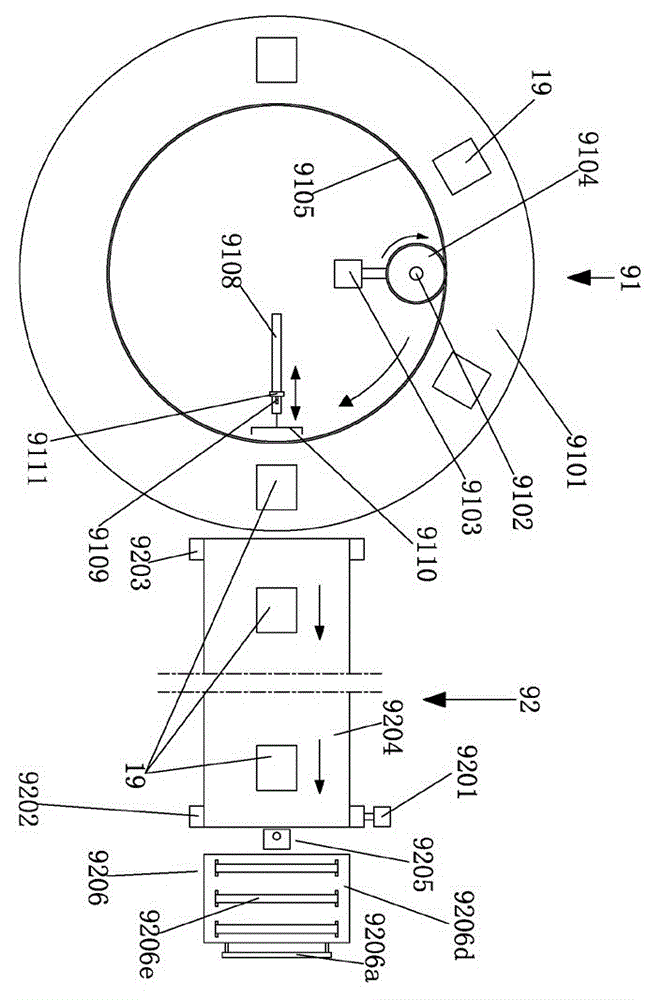

[0021] Such as Figure 1-2As shown, an intelligent assembly line for cleaning trash cans includes a cleaning bin 1 fixed on the ground, a delivery line 9 that can transport the trash bin 19 to the cleaning bin 1, and a general controller 20. One side of the cleaning bin 1 is provided with The inlet 1a, the output end of the conveying line 9 is facing the inlet 1a, and the other side of the cleaning bin 1 is provided with an outlet 1b; both the inlet 1a and the outlet 1b of the cleaning bin 1 are equipped with a turning mechanism 7 and a bucket clamping mechanism for clamping the trash can 19 8. The barrel clamping mechanism 8 is fixedly installed on the turning mechanism 7. The barrel clamping mechanism 8 can be turned over under the control of the turning mechanism 7 and can enter and exit the cleaning chamber 1; The outer wall cleaning unit 21, the conveying unit for conveying the garbage can 19, the inner wall cleaning mechanism 16 for cleaning the inner wall of the garbage...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com