A preparation method of graphene/fe3o4/polyaniline ternary wave-absorbing composite material

A composite material and graphene technology, which is applied in the production field of ternary composite conductive materials, can solve the problems of low magnetic permeability, poor impedance matching, and high complex permittivity, so as to improve impedance matching, realize impedance matching, increase The effect of specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

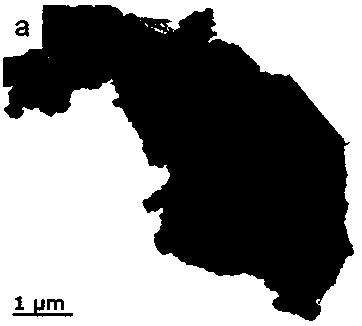

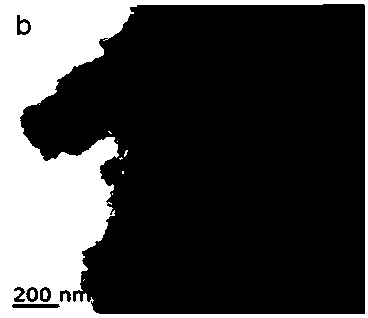

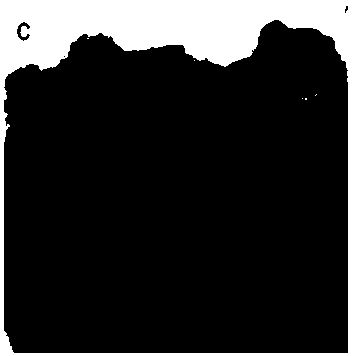

Image

Examples

Embodiment 1

[0027] Weigh graphite oxide and Fe first 3 O 4 0.186g each was put into 150mL deionized water, ultrasonic for 30min to make it fully dispersed; secondly, the above suspension was transferred into a three-necked flask, and then 0.558g aniline was added and heated in a 95℃ water bath for 4h; then the water bath was cooled to 0~ At 5°C, add 7.5 g of acetic acid and stir for 0.5 h to make the pH of the mixed system 0.

[0028] 1.824g of ammonium persulfate was dissolved in 50mL of deionized water, and then slowly dropped into the above mixed system for 1h to carry out oxidative polymerization for 24h.

[0029] Finally, the prepared graphene / Fe 3 O 4 The / PANI composite material was washed and centrifuged with ethanol and distilled water, and dried in an oven at 80°C for 12-24 hours to obtain powder materials.

Embodiment 2

[0031] Weigh graphite oxide and Fe first 3 O 4 0.186g each was put into 150mL deionized water, ultrasonic for 30min to make it fully dispersed; secondly, the above suspension was transferred to a three-necked flask, and 0.558g aniline was added, and heated in a 95℃ water bath for 4 hours; then the water bath was cooled to 0~ At 5°C, add 7.5 g of acetic acid and stir for 0.5 h to make the pH value of the mixed system 4.

[0032] Dissolve 2.188 g of ammonium persulfate in 50 mL of deionized water, and then slowly add dropwise to the above mixed system for 1 hour for oxidative polymerization for 24 hours.

[0033] Finally, the prepared graphene / Fe 3 O 4 The / PANI composite material was washed with ethanol and distilled water, centrifuged, and dried at 80°C for 12-24 hours to obtain powder materials.

Embodiment 3

[0035] Weigh graphite oxide and Fe first 3 O 4 0.186g each was put into 150mL deionized water, ultrasonic for 30min to make it fully dispersed; secondly, the above suspension was transferred to a three-necked flask, and 0.558g aniline was added, and heated in a 95℃ water bath for 4 hours; then the water bath was cooled to 0~ At 5°C, add 7.5 g of acetic acid and stir for 0.5 h to make the pH of the mixed system 3.

[0036] Dissolve 2.736 g of ammonium persulfate in 50 mL of deionized water, and then slowly add dropwise to the above mixed system for 1 hour for oxidative polymerization for 24 hours.

[0037] Finally, the prepared graphene / Fe 3 O 4 The / PANI composite material was washed with ethanol and distilled water, centrifuged, and dried at 80°C for 12-24 hours to obtain powder materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com