Mixed-phase tungsten sulfide modified cuprous oxide double-layer hydrogen evolution photoelectrode and its preparation

A cuprous oxide and tungsten sulfide technology, applied in the field of photoelectrodes, can solve the problems of reducing photoelectric conversion efficiency or hydrogen production in the catalytic process, no reports on cuprous oxide double-layer hydrogen evolution photoelectrodes, and reducing catalyst reaction activity, etc. Achieve the effect of improving photoelectric conversion efficiency, high photoelectric hydrogen evolution efficiency, and improved electrocatalytic hydrogen evolution activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

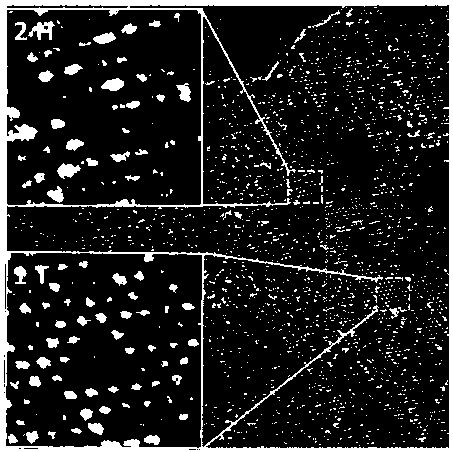

Embodiment 1

[0021] Prepared CuSO 4 (0.05M) and trisodium citrate (0.05M) mixed solution 50mL, then use 1M NaOH solution to adjust its pH value to 11.0, use oil bath to heat the mixed solution to 65 o C, then FTO (1cm×2cm) glass was used as the working electrode, Ag / AgCl was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode to prepare Cu by electrodeposition under the condition of -0.4V vs Ag / AgCl for 2h 2 O thin film photoelectrode. Weigh 2.38 g solid WS 2 (9.6 mM) powder was poured into a dry 50ml Shrek tube equipped with a magnet, and the air in the tube was replaced with argon, then 6ml of 2.4M n-butyl lithium in n-hexane solution was added, sealed and heated in an oil bath to 66 o C, continuous reaction for 24h. Suction filtration, dry the product with argon, add deionized water, and then centrifuge at 14000rpm to remove unstripped solid WS 2 , you can get M-WS 2 Aqueous solution, 1T-WS 2 accounted for mixed-phase tungsten sulfi...

Embodiment 2

[0023] Formulated Cu 2 SO 4 (0.06M) and trisodium citrate (0.06M) mixed solution 50mL, then use 1M NaOH solution to adjust its pH value to 11.0, use an oil bath to heat the solution to 65 o C, then FTO (1cm×2cm) glass was used as the working electrode, Ag / AgCl was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode to prepare Cu by electrodeposition under the condition of -0.4V vs Ag / AgCl for 1.5h 2 O thin film photoelectrode. Weigh 2.38g solid WS 2 (6μm) powder into a clean anhydrous 50ml Shrek tube equipped with magnetons, replace the air in the tube with argon, then add 8ml of 2.4M n-butyl lithium in n-hexane solution, seal it and use an oil bath Heat the reactants to 66 o C, continue to react for 30h. Suction filtration, dry the product with argon, add deionized water, and then centrifuge at 14000rpm to remove unstripped WS 2 , you can get M-WS 2 (1T-WS 2 The mass percentage is 55%). The stripped M-WS 2 The solubili...

Embodiment 3

[0025] Formulated Cu 2 SO 4 (0.08M) and trisodium citrate (0.08M) mixed solution 50mL, then use 1M NaOH solution to adjust its pH value to 11.0, use an oil bath to heat the solution to 65 o C, then FTO (1cm×2cm) glass was used as the working electrode, Ag / AgCl was used as the reference electrode, and the platinum sheet electrode was used as the counter electrode to prepare Cu by electrodeposition under the condition of -0.4V vs Ag / AgCl for 1h 2 O thin film photoelectrode. Weigh 2.38g solid WS 2 (6μm) powder is poured into a clean anhydrous Shrek tube (50ml) equipped with magnetons, and the air in the tube is replaced by argon, and then 10ml of 2.4M n-butyllithium in n-hexane solution is added, and after sealing, use oil Heat bath to 66 o C, for 36 hours. Suction filtration, dry the product with argon, add deionized water, and then centrifuge at 14000rpm to remove unstripped WS 2 , the mixed-phase WS can be obtained 2 (1T-WS 2 The quality score is 65%). The stripped mi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com