Special low-dry-fading wide-color-gamut fluorescent ink for 10-micron frequency modulation screen

A technology of fluorescent ink and frequency modulation net, which is applied in the field of offset printing ink to achieve the effect of increasing wetting and dispersibility, avoiding uncomfortable feeling and reducing gloss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

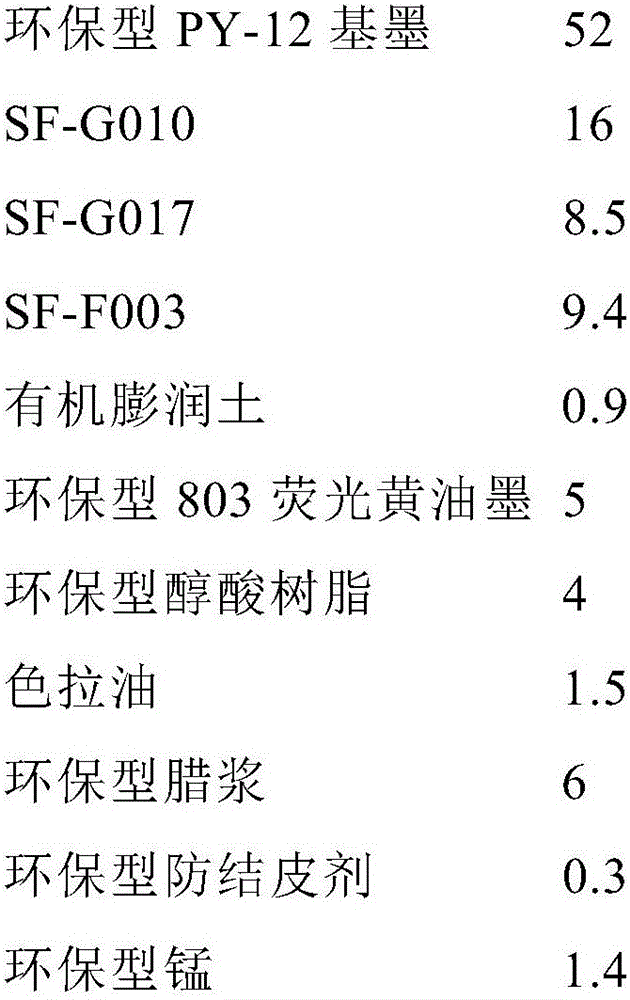

[0058] 10 micron FM screening special yellow ink formula:

[0059]

[0060] Yellow ink property measurement results: viscosity 10, viscosity 53s, fluidity 35.5mm, fineness 12.5μ, water resistance 51%, fixation speed 6 minutes, gloss 52, dry fade value 0.

Embodiment 2

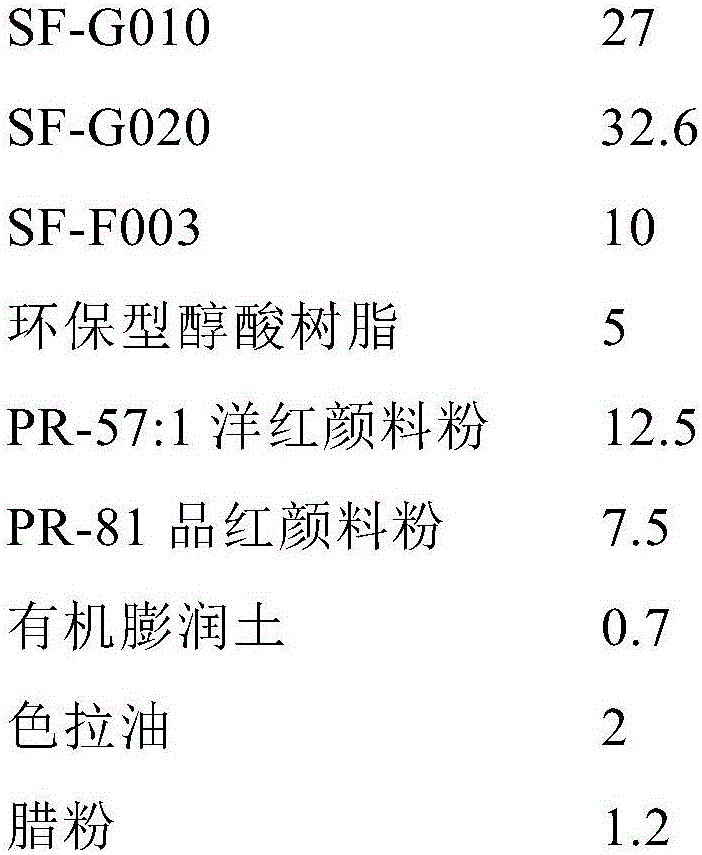

[0062] Magenta ink formula for 10 micron FM screening:

[0063]

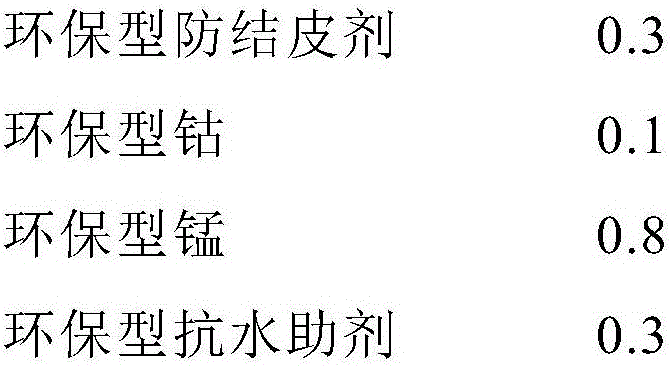

[0064]

[0065] Magenta ink property measurement results: viscosity 10.8, viscosity 68s, fluidity 33mm, fineness 12.5μ, water resistance 43%, fixation speed 6 minutes, gloss 54, dry fade value 0.04.

Embodiment 3

[0067] 10 micron FM screening special blue ink formula:

[0068]

[0069] The measurement results of blue ink properties: viscosity 11.3, viscosity 67s, fluidity 31mm, fineness 12.5μ, water resistance 45%, fixation speed 6 minutes, gloss 53, dry fade value 0.03.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Liquidity | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

| Liquidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com