Prefabricated assembled subway station tenon-and-groove connector capable of monitoring water leakage

A prefabricated assembly and subway station technology, applied in water conservancy projects, protection devices, underwater structures, etc., can solve problems such as poor waterproofness of joints, and achieve the effect of enhancing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation manners of the present invention will be described in detail below in conjunction with the technical solutions (and accompanying drawings).

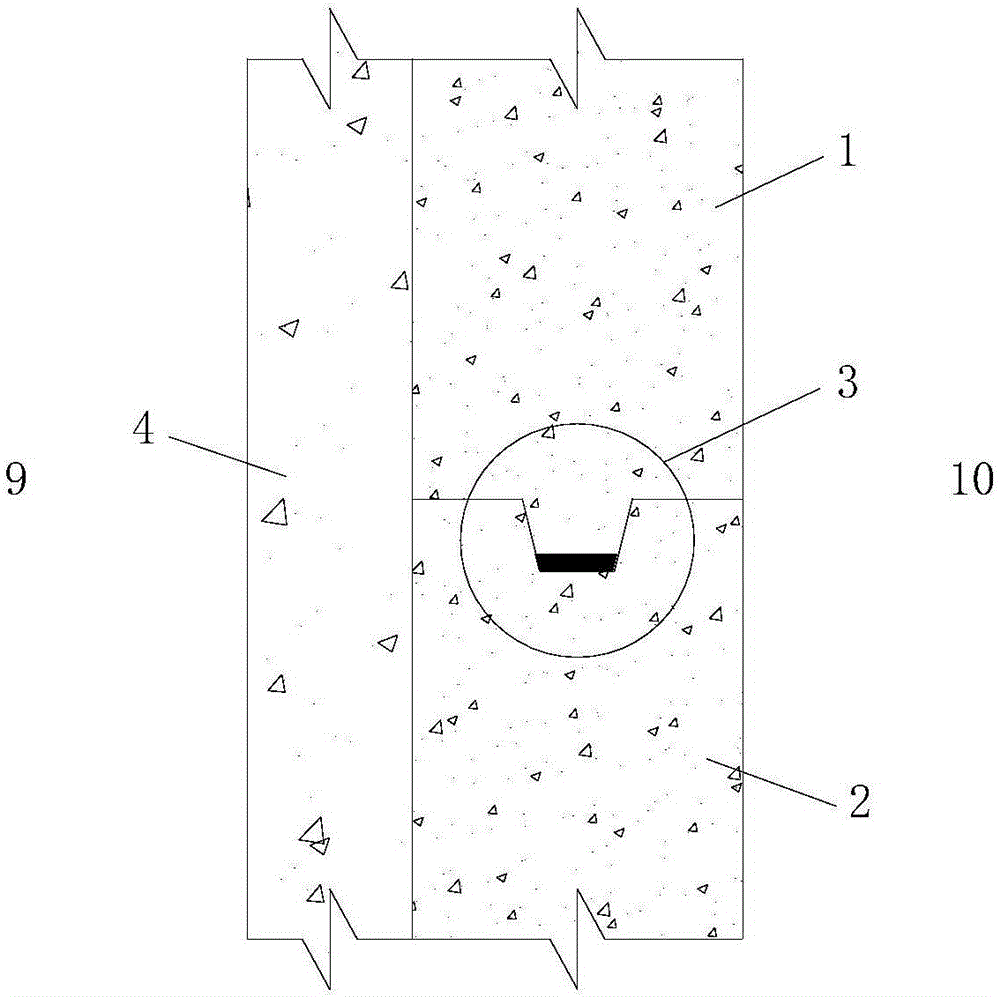

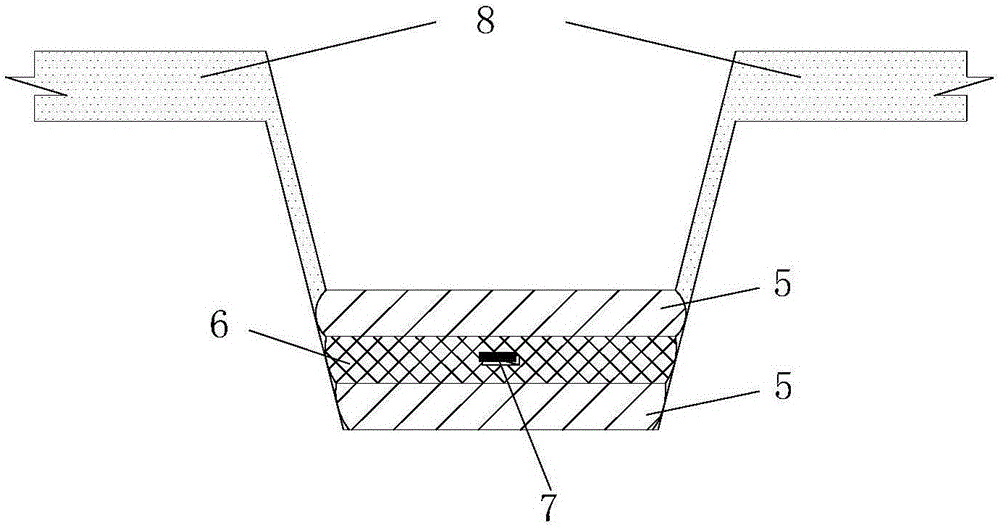

[0015] A prefabricated assembled subway station tongue-and-groove joint capable of monitoring water leakage, including a tenon-shaped component 1, a tongue-and-groove component 2, a junction 3, an elastic rubber pad 5, a water-swellable rubber pad 6, and a pressure sensor 7;

[0016] The joint 3 between the tenon-shaped component 1 and the tenon-groove component 2 is the prefabricated subway station tongue-and-groove joint. The joint 3 is provided with three layers of rubber pads, the upper and lower layers are elastic rubber pads 5, and the middle is water-swellable The rubber pad 6, the pressure sensor 7 is embedded in the water-swellable rubber pad 6;

[0017] The upper elastic rubber pad 5 is pasted on the tenon member 1, the lower elastic rubber pad 5 is pasted on the tenon and groove member 2, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com