Rubber air spring damper capable of adjusting early stage rigidity

A rubber air spring and damper technology, which is applied in the direction of building components, shockproof, building types, etc., can solve the problems of reducing the cost of shock absorption, waste of resources, and the inability to change the early stiffness of the damper, so as to reduce the cost of shock isolation and shorten the length Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

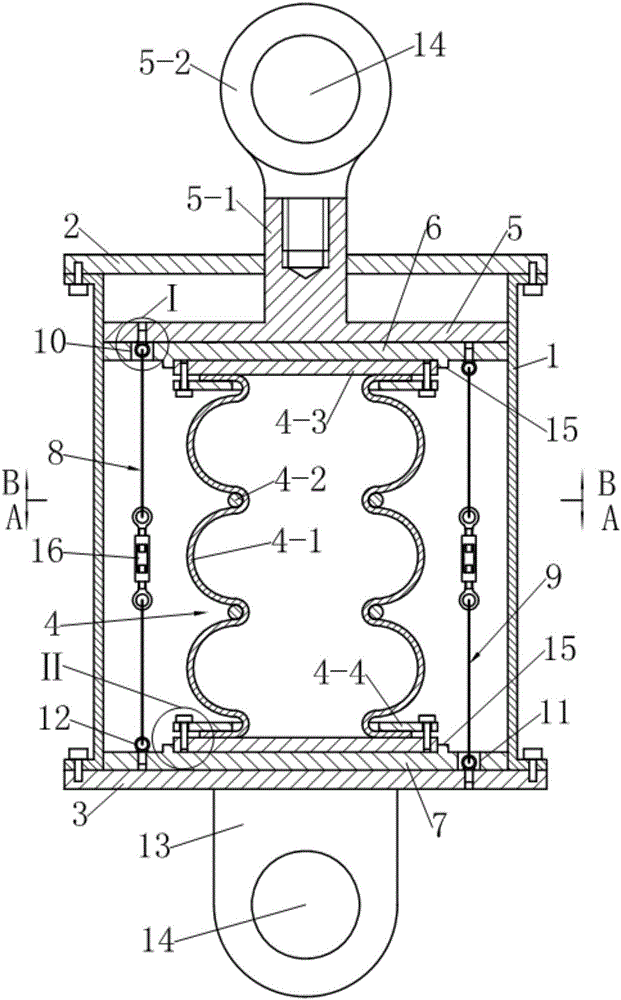

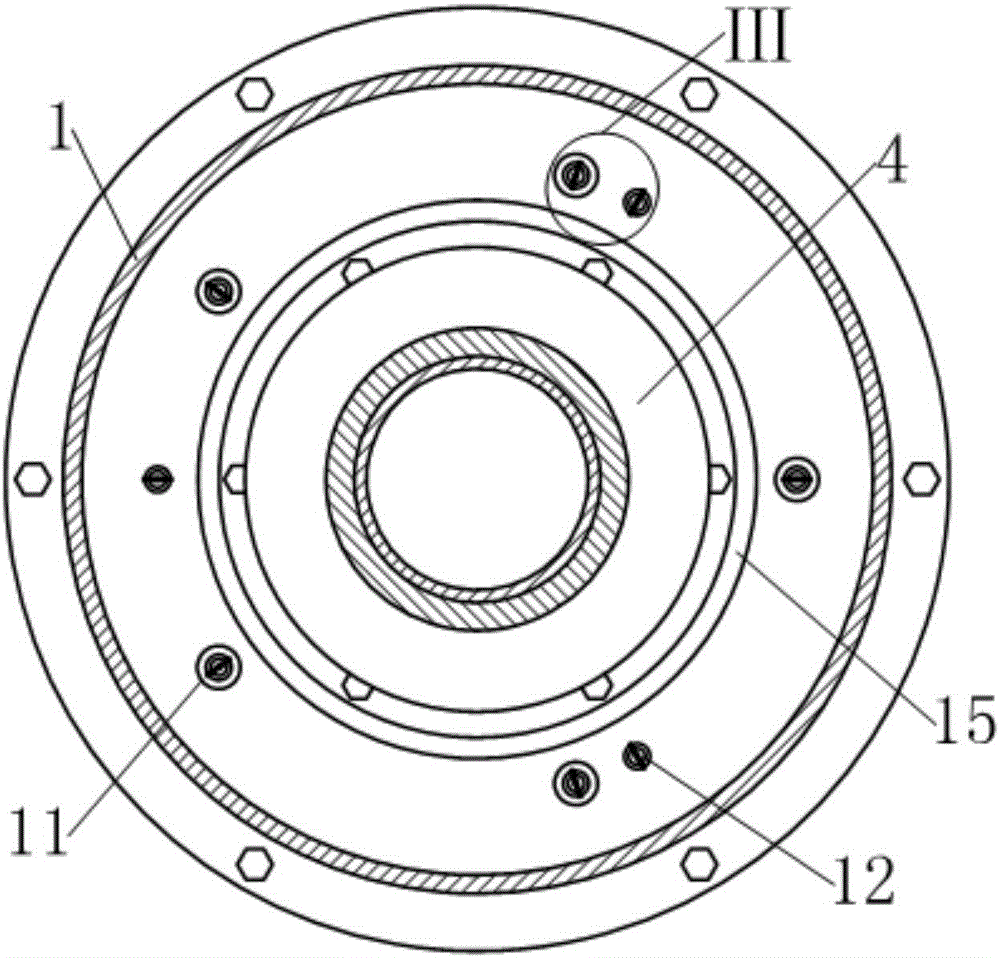

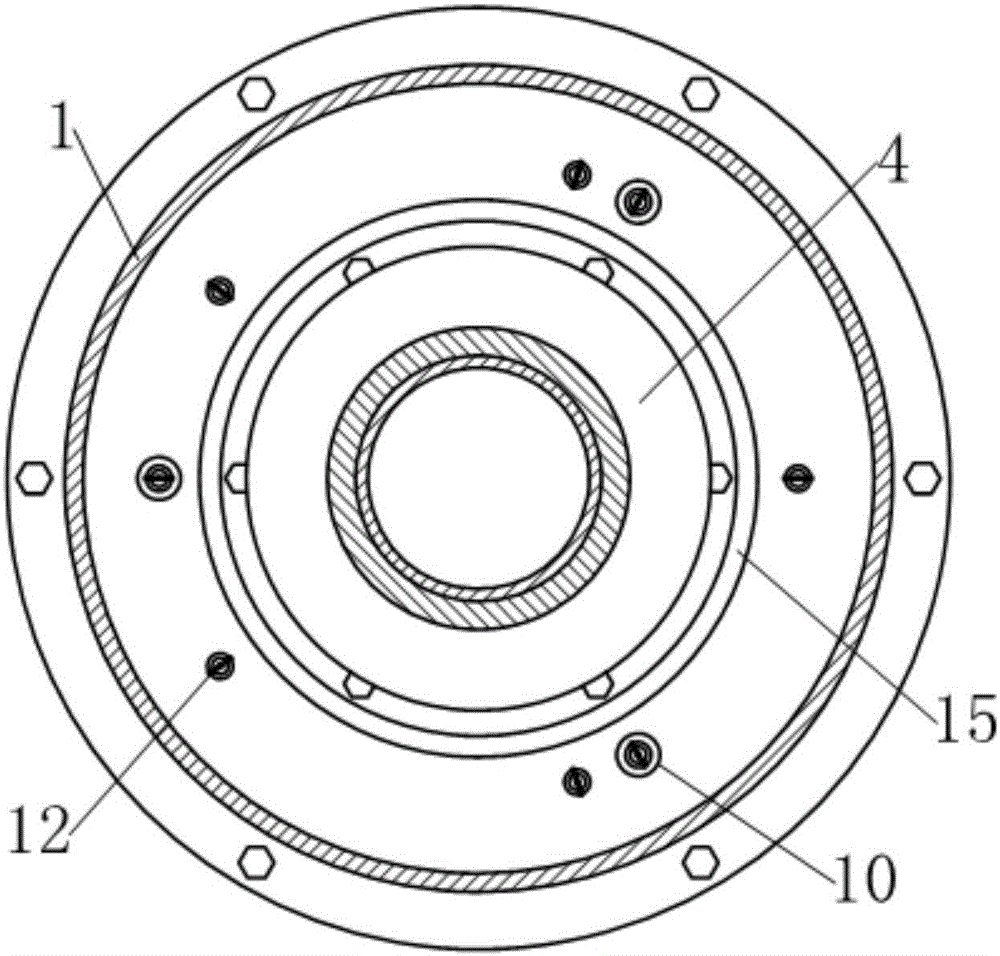

[0033] see figure 1, the rubber air spring damper that can adjust the early stiffness in this example is a kind of energy dissipation device that can be used for seismic reinforcement of building structures. It includes a guide sleeve 1, a first end cover 2 and a second Two end caps 3, wherein the first end cap 2 and the second end cap 3 are respectively fixedly connected to the two ends of the guide sleeve by screws. A rubber air spring 4 is arranged axially in the guide sleeve 1, and a driving member extends from the center of the first end cover 2 into the guide sleeve 1 and presses on the rubber air spring 4; wherein, the The driving member is composed of a dynamic pressure plate 5 located at the upper end of the rubber air spring 4 and movably matched with the guide sleeve 1, and a driving rod 5-1 extending upward from the upper surface of the dynamic pressure plate 5 out of the guide sleeve 1. The driving rod 5-1 is located at The outer end of the guide sleeve 1 is pro...

example 2

[0044] see Figure 8-11 , this example has the following differences from Example 1:

[0045] Both the first group of preloaded steel cables 8 and the second group of preloaded steel cables 9 are composed of three preloaded steel cables. The number of said rigging turnbuckles 16 is reduced to six, and they are connected in series in the middle of each preloaded steel cable respectively.

[0046] The implementation method of this example except the above is the same as Example 1.

example 3

[0048] see Figures 12 to 14 , the rubber air spring damper that can adjust the early stiffness in this example is a kind of vibration isolation device (also called seismic isolation support) that can be used for vertical isolation of buildings. Compared with Example 2, this example has the following main differences :

[0049] 1. As a shock-absorbing support, in order to facilitate installation, in this example, the connecting lug plate provided on the second end cover 3 is omitted, and the second end cover 3 is radially extended from the edge outward, and evenly distributed at the edge A connecting bolt hole 17 is provided, and the second end cover 3 is used as the base of the shock-absorbing support. The driving rod 5-1 of the driving member is a metal tube fixedly connected to the upper surface of the dynamic pressure plate 5 by bolts, and the end of the metal tube located outside the guide sleeve 1 is provided with a connecting bracket 18, and the connecting bracket Bol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com