Waste brick veneer prefabricated heat-insulating external wall panel and manufacturing method thereof

A technology for thermal insulation of external walls and thermal insulation boards, which is applied in the direction of walls, building components, coverings/linings, etc., can solve problems such as the ineffective reuse of fired clay bricks, and the reverse production of prefabricated decorative exterior wall panels, etc., to achieve guaranteed Firmness and the effect of improving mounting accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

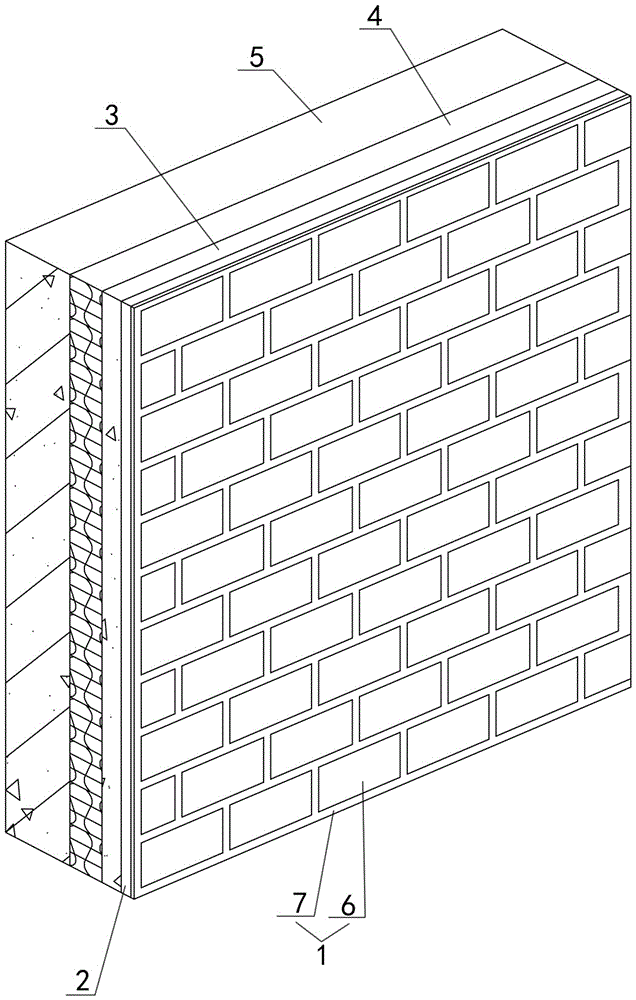

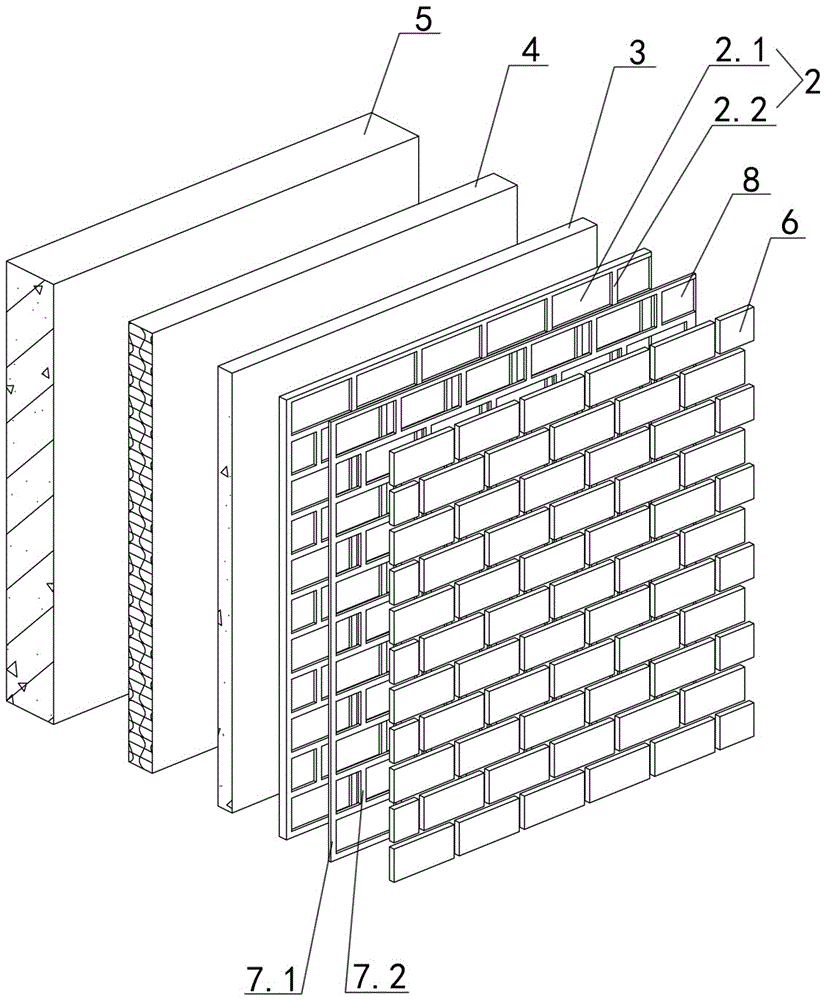

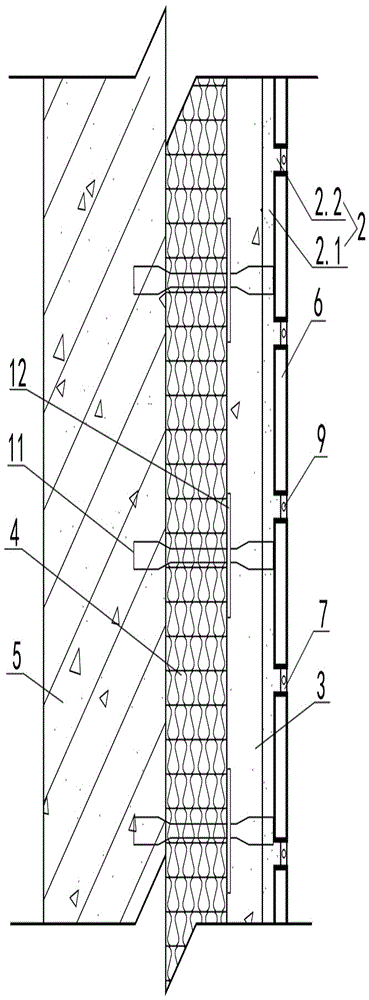

[0045] Examples see Figure 1-4 As shown, a waste brick veneer prefabricated thermal insulation exterior wall panel includes a panel body, and the panel body includes a wall base layer 5, an insulation layer 4, an insulation board protection layer 3, a mortar layer 2, Finishing assembly layer 1 and thermal insulation connector 11,

[0046] The veneer assembly layer 1 includes a group of waste brick slices 6 arranged in sequence and a silica gel grid assembly mold 7. The silica gel grid assembly mold 7 is in the shape of a flat plate, and a set of waste brick slices 6 is formed on the plate. Arrangement position, number and size of waste brick slices corresponding to the receiving through holes 8, the silica gel mesh assembly mold 7 is provided with a steel skeleton 9 at the position avoiding the receiving through holes, the waste bricks The slices 6 are all embedded in the receiving through holes 8 at the corresponding positions, and the outer surface of the waste brick slice...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com