A rocket engine external fastening device

A rocket engine and fastening device technology, which is applied to rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of large gaps and falling off of missile engine pin connection structures, and achieve simple structure, simple installation, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

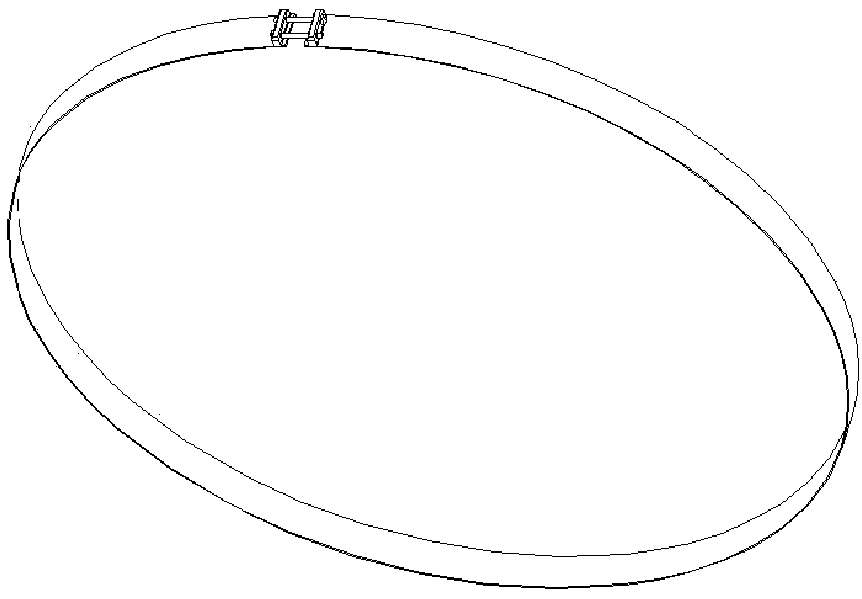

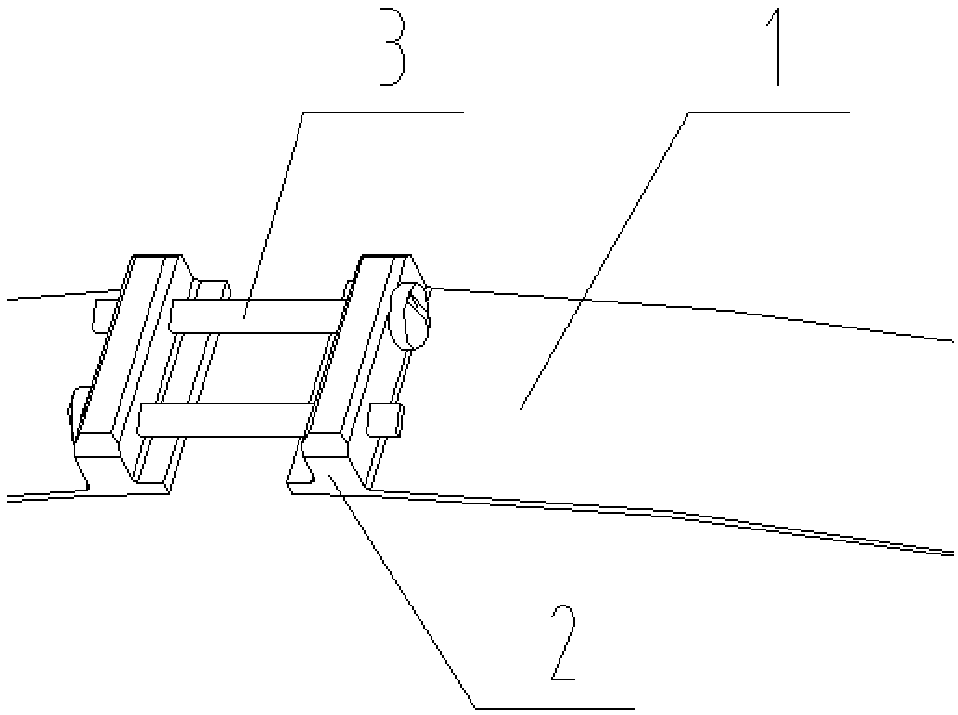

[0022] The rocket motor external fastening device proposed by the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. It should be noted that the drawings are all in a very simplified form and use imprecise ratios, which are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0023] figure 1 and figure 2 It is a schematic diagram of an external fastening device of an air-to-air missile double-pulse solid rocket motor pin connection structure of the present invention. The external fastening device is used for a pin connection structure and is composed of a strap and a screw 3; The body 1 and the taping head 2 are welded; the taping head 2 contains a through hole and a threaded hole; after the two taping heads 2 are welded to both ends of the taping body 1, the through holes on both sides correspond to the threaded holes one by one; the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com