Directly heating heat pump water heater water tank

A heat pump water heater and water tank technology, which is applied to fluid heaters, lighting and heating equipment, mechanical equipment, etc., can solve the problems of uneven temperature distribution in the water tank, obvious stratification of cold and hot water, and low temperature dead corners in the water tank, and achieve smooth and rapid water flow. , Improve the degree of automation and reliability, and reduce the effect of circulating heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

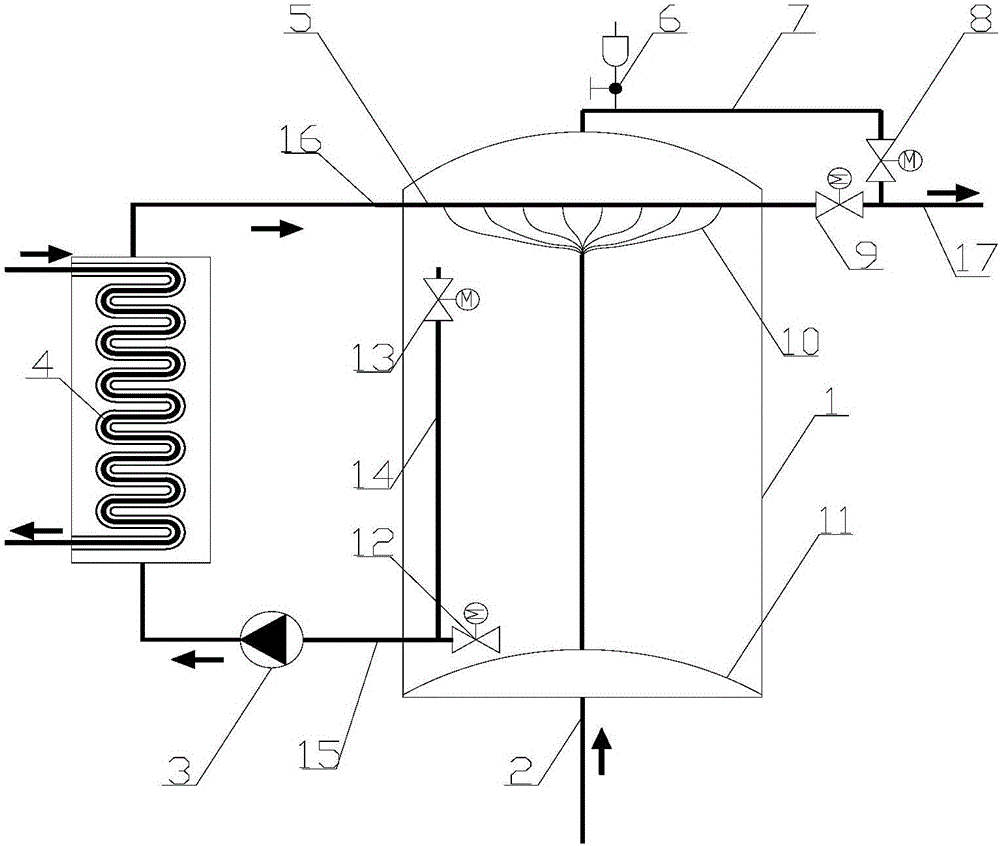

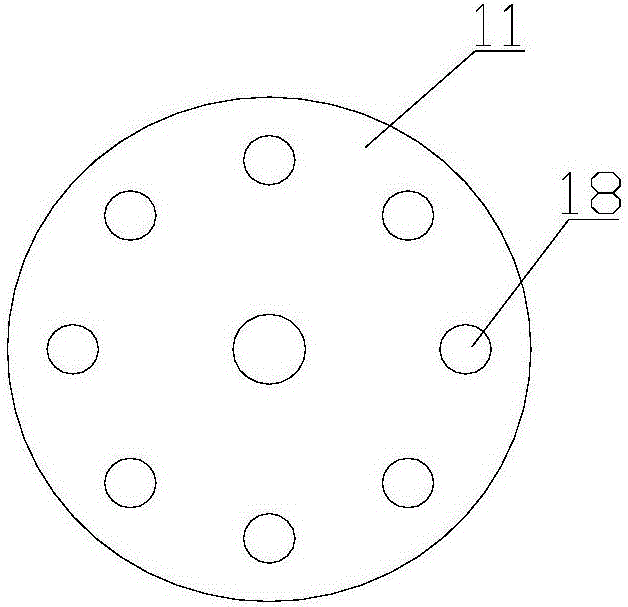

[0023] refer to figure 1 , 2 , a water tank of a direct heat heat pump water heater according to the present invention, comprising a water tank body 1, a tap water inlet 2, a circulating water pump 3, a hot water main pipe 5, a hot water branch pipe 7, a first electromagnetic valve 8, a second electromagnetic valve 9, and several capillary tubes 10 , clapboard 11, the 3rd solenoid valve 12, the 4th solenoid valve 13 and the suction pipe 14, the lower front side of described water tank body 1 is provided with cold water outlet 15, and described cold water outlet 15 is provided with in water tank body 1 The third electromagnetic valve 12 and the water suction pipe 14, the water suction pipe 14 absorbs the water in the top of the water tank body 1, the water suction pipe 14 is arranged in front of the third electromagnetic valve 12, and the water suction pipe 14 is provided with a fourth Electromagnetic valve 13, the input end of the circulating water pump 3 is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com