Adaptive Design Method for Horizontal Axis Wind Turbine Blades

A technology of wind turbine blades and design methods, which is applied to wind turbines, wind turbines consistent with the wind direction, mechanical equipment, etc., can solve the problems of prolonging the design cycle of blades, increasing the cost of blade design and manufacturing, waste, etc., and shortening research and development and manufacturing cycle, improve design efficiency, and highly targeted effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with the drawings.

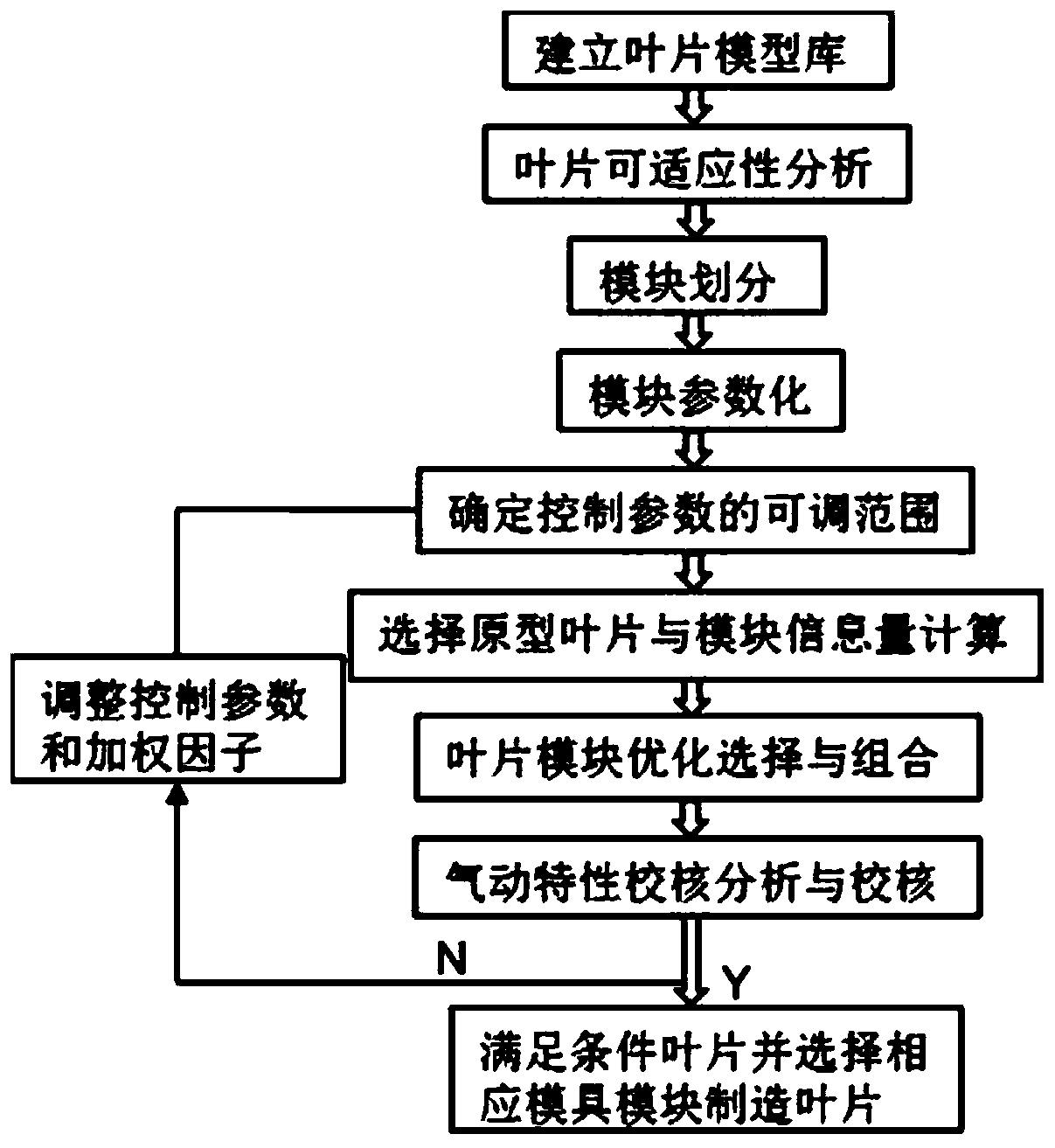

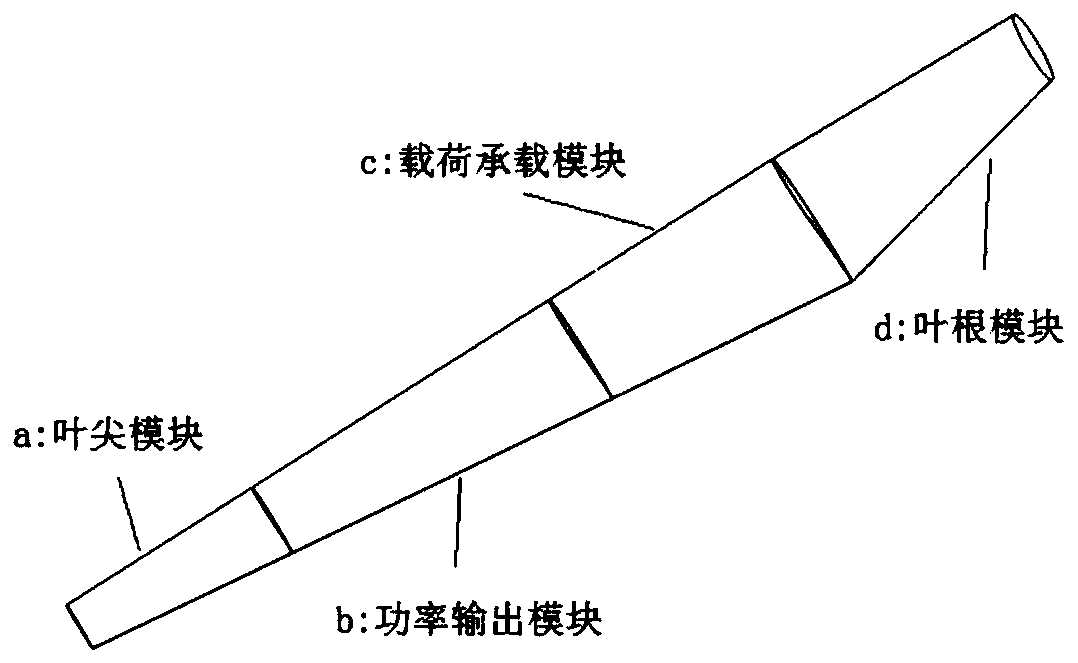

[0058] The present invention performs aerodynamic and structural adaptability analysis on horizontal axis fan blades, modularizes the blades on the basis of the analysis, and establishes a module parameterized database. On the basis of the prototype blade, the blade parameters are modified in a small range by replacing specific modules to design a fan blade that meets customer needs. The present invention is suitable for situations where there is little difference in demand between different customers or the range of difference between new and old demands of the same customer is small. The flowchart of the adaptive design method of the present invention is as follows figure 1 Shown.

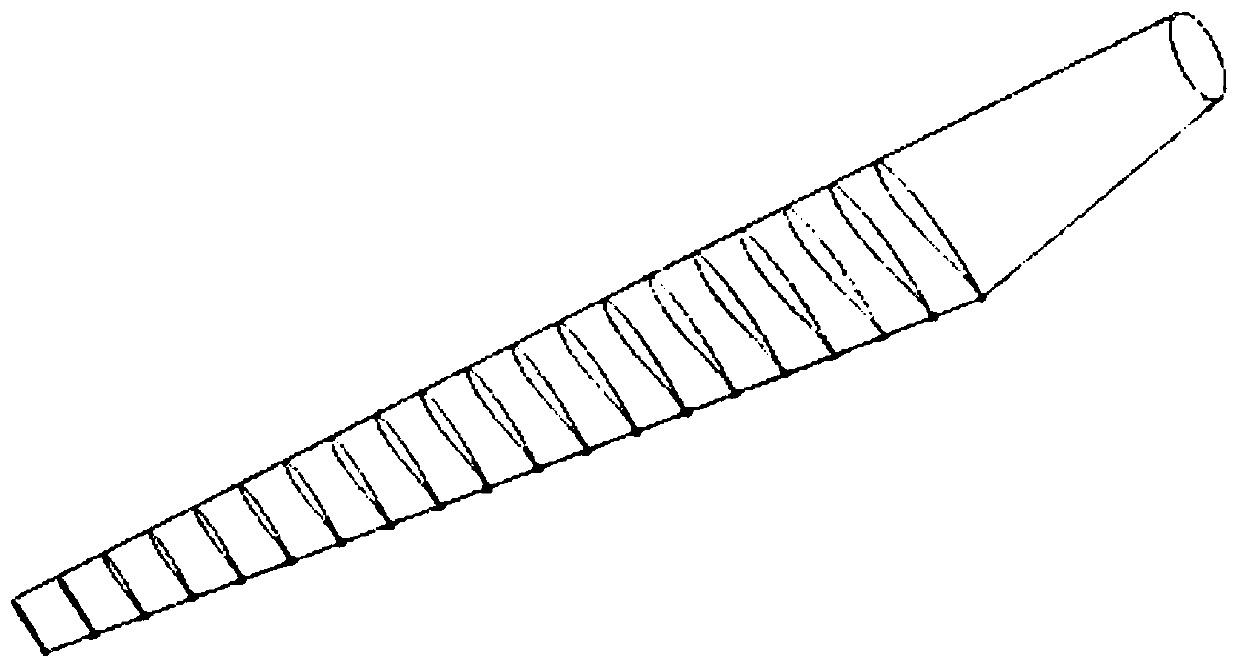

[0059] (1) Establish a blade model library containing different specifications and models. Since the wind turbine information is company and enterprise secrets, the present invention uses the existing bla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com