Split powder spray gun sprayer

A split type, powder technology, applied in the direction of liquid injection device, injection device, etc., can solve the problems of not meeting the use requirements, high use cost, inconvenient disassembly and assembly, etc., and achieve the effect of good use effect, reasonable structure and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

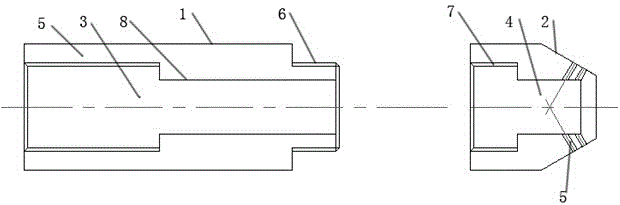

[0014] Such as figure 1 As shown, a split-type powder spray gun nozzle of the present invention includes a shell and a powder supply pipeline arranged inside the shell, the shell includes a shell A1 and a shell B2, and the powder supply pipeline includes a powder supply pipeline A3 and a powder supply pipeline B4 , the shell A1 is set outside the powder supply pipeline A1, the shell B2 is set outside the powder supply pipeline B4, the shell A1 and the shell B2 are detachably connected, and the powder supply pipeline A3 and the powder supply pipeline B4 are detachably connected , the front end of the powder supply pipeline B4 is sequentially provided with multiple groups of discharge groups along the length direction of the powder supply pipeline B4, and each group of discharge groups includes a plurality of discharge groups arranged along the circumferential direction of the powder supply pipeline B4 Mouth 5.

[0015] Preferably, as a possible embodiment, the front end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com