A temperature-measuring layer molding process for a thermal insulation container

A thermal insulation container and molding process technology, applied in the direction of coating, etc., can solve the problems of inconvenience, vibration of the thermal insulation container, and difficulty in obtaining the actual temperature of the inner cavity of the airtight thermal insulation container, and achieve the effect of temperature measurement function protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

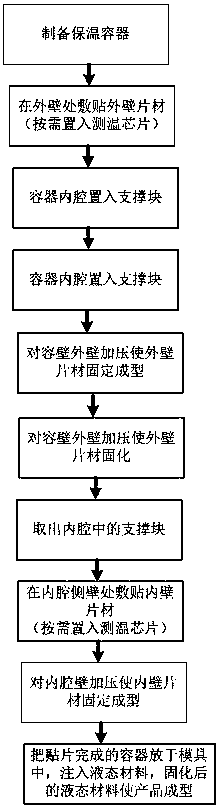

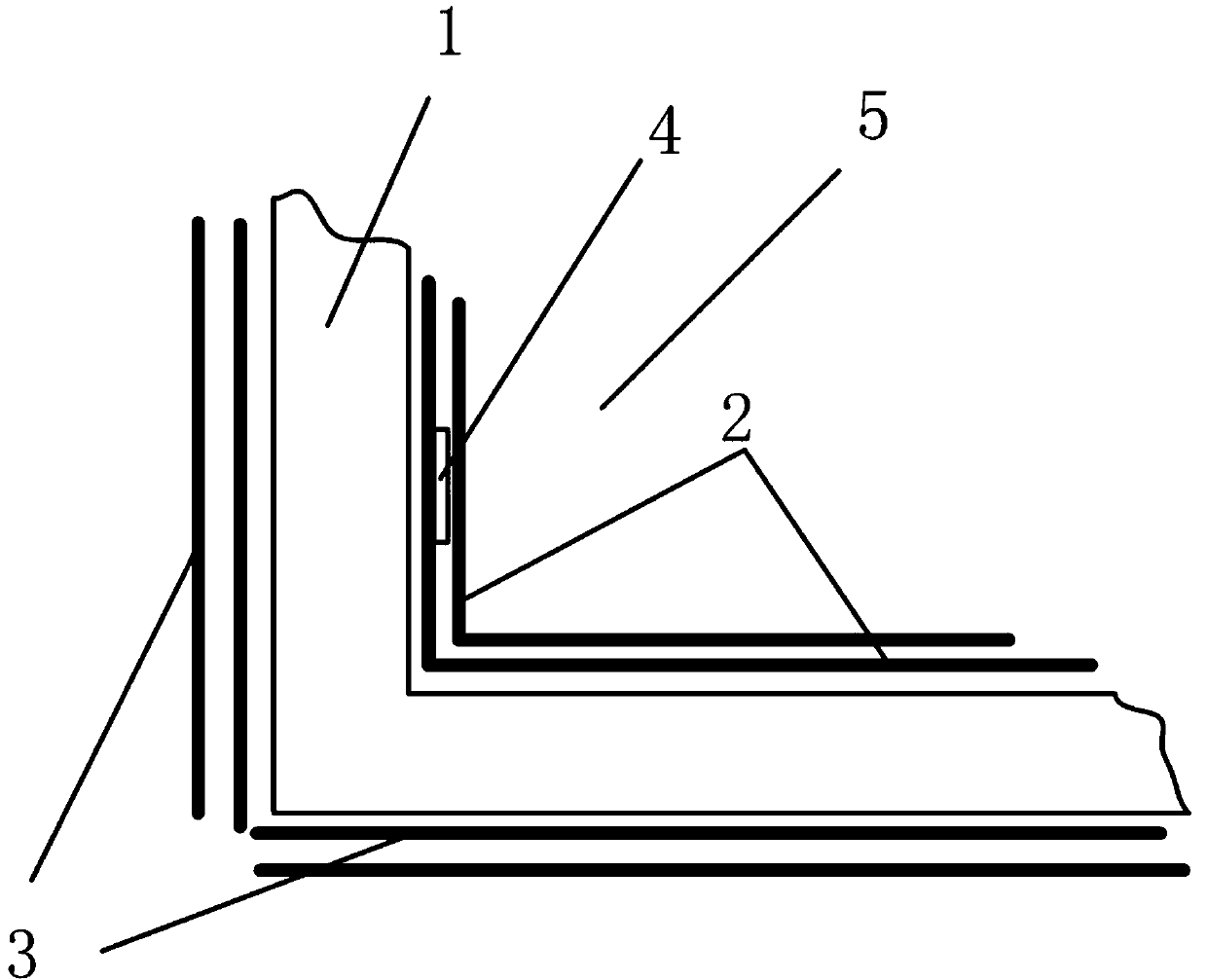

[0028] like figure 1 , 2 As shown, a temperature-measuring layer molding process of a thermal insulation container is used to form a surface layer with a temperature-measuring chip 4 at a thermal insulation container 1. It is characterized in that: the molding process includes the following steps in sequence.

[0029] A1. Prepare the thermal insulation container 1 with foam material.

[0030] A2. Apply multi-layer outer wall sheets 3 on the outer surface of the heat preservation container. When it is necessary to place the temperature measuring chip 4 on the outer surface, place the temperature measuring chip on the adjacent two layers of outer wall sheets 2 in this step. middle.

[0031] A3. Put a hard support block into the inner cavity 5 of the heat preservation container, so that the outer surface of the support block is in contact with the inner cavity wall of the heat preservation container to form a support to prevent the wall of the heat preservation container from s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com