Stopper

A technology of blocker and blocker, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of inability to use, low work efficiency, unfavorable economic efficiency, etc., to reduce the height of the body, reduce the space occupied, and improve work efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A preferred embodiment of the present invention will be described below with reference to the accompanying drawings.

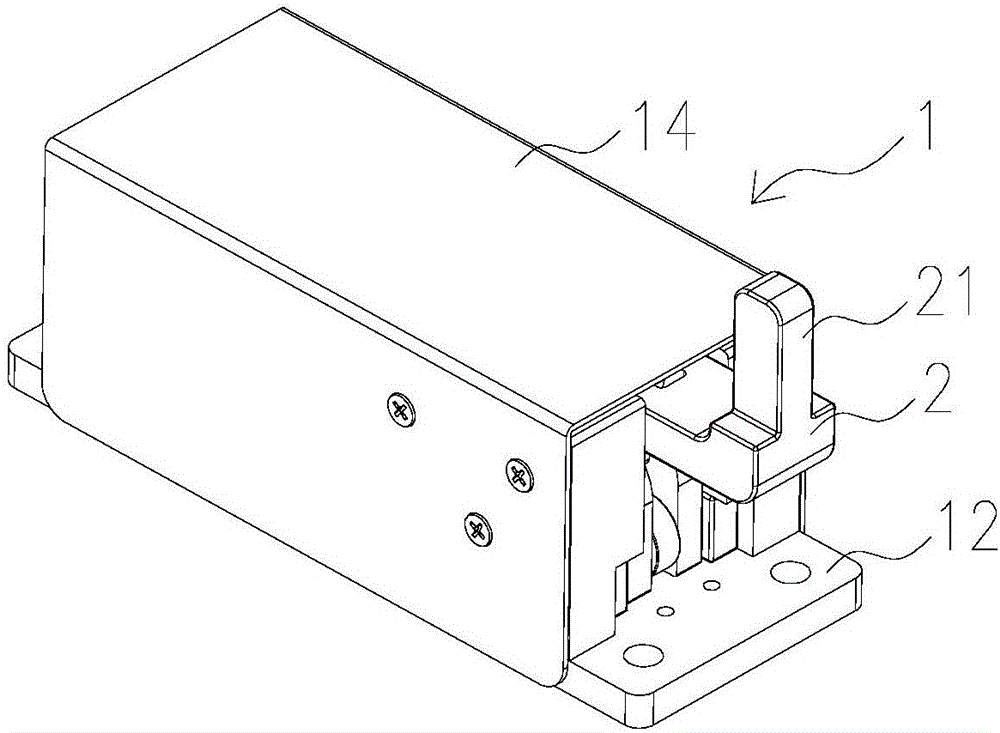

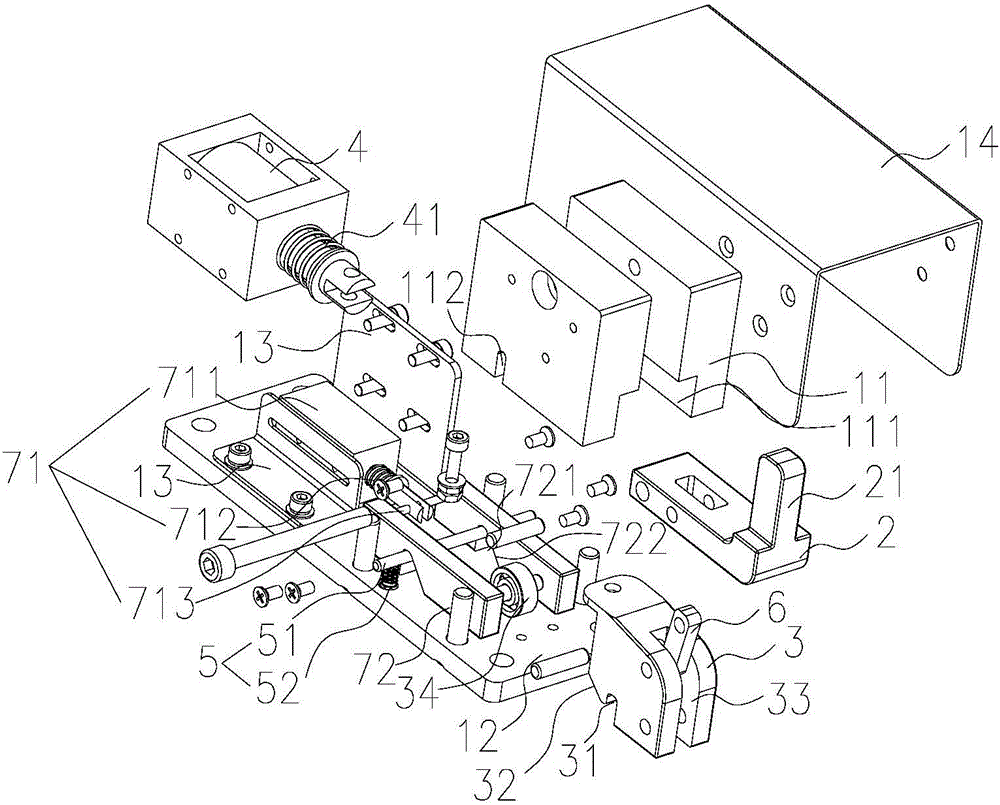

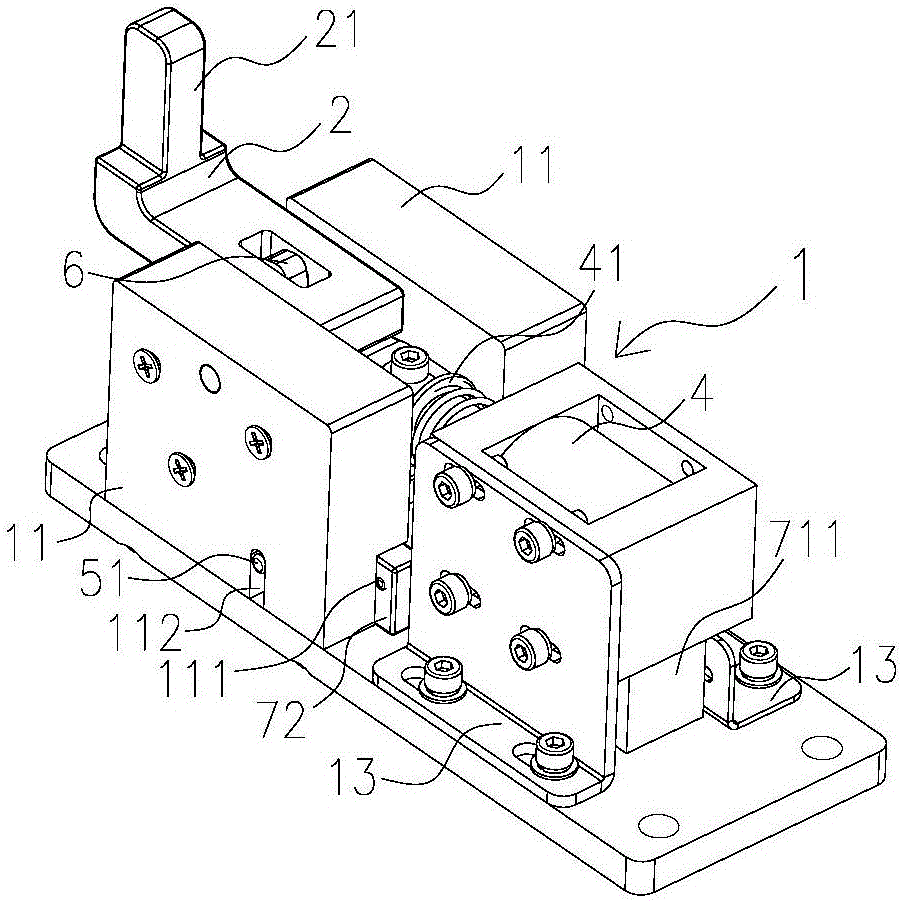

[0025] see Figures 1 to 6 , the stopper of the present invention includes a frame 1, a stopper 2, a slide seat 3, a first traction electromagnet 4, a first reset mechanism 41 and a locking mechanism 5, and the head end of the stopper 2 is connected to the frame 1 is hinged, the tail of the blocking member 2 is provided with a blocking portion 21, the blocking member 2 is hinged to the sliding seat 3 through the connecting rod 6, and the traction rod of the first traction electromagnet 4 is connected to the sliding seat 3; The first traction electromagnet 4 drives the slide seat 3 to move to the first traction electromagnet 4 side to make the blocking part 21 turn down to realize storage. When the slide seat 3 moves to the locked position, the locking mechanism 5 locks the slide seat 3 and unlocks the locking mechanism. 5. The first reset mechanism 41 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com