Moving bed biofilm reactor

A moving bed biofilm and reactor technology, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve poor nitrogen removal effect, affect sewage treatment effect, aeration Inhomogeneity and other problems, to achieve the effect of good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

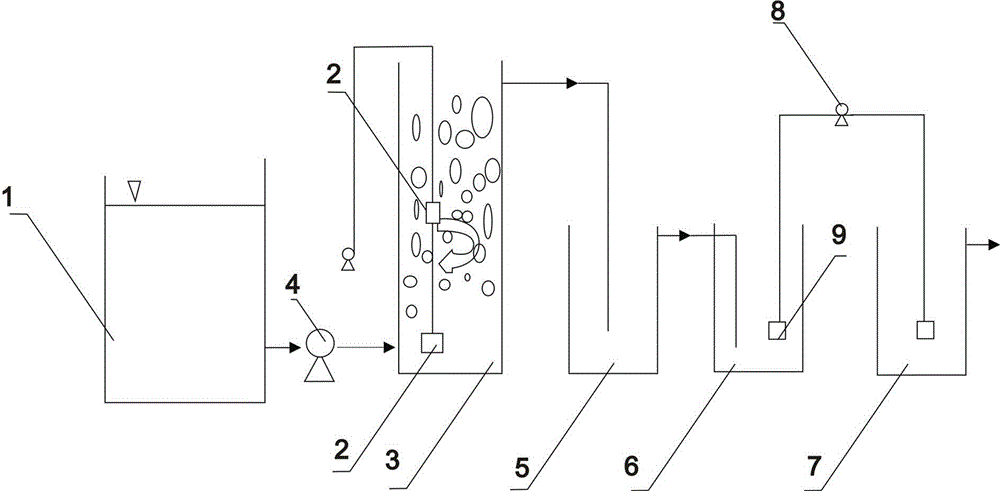

[0006] The invention provides a moving bed biofilm reactor, which includes a water pump 4 and an MBBR reactor 3 . The water pump pumps the water in the sewage pool into the MBBR reactor. When the MBBR is started, the influent quality concentration is low. The air pump 4 of the reactor is connected to the aeration device. The aeration devices 2 and 3 are respectively arranged in the middle and At the bottom, the amount of aeration is adjusted to just fully fluidize the fill. The biofilm on the filler in the early stage of treatment is very thin, so it requires a lot of energy to fluidize it, and the hydraulic retention time is long at the beginning, so the air-water ratio is as high as 25:1. As the influent flow rate increases, the hydraulic retention time becomes shorter and the biofilm on the filler becomes thicker. At this time, the energy consumption for completely fluidizing the filler becomes smaller, and the air-water ratio is about 10:1 to 15:1.

[0007] When the MBBR ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com