A cold heading deformable zinc alloy and its application

A technology of zinc alloy and cold heading, which is applied in the direction of contact parts, connecting contact materials, etc., can solve the problems of unsatisfactory comprehensive performance and failure to develop deformed zinc alloy, and achieve coordinated shear resistance and excellent cold heading performance , high elongation and shear strength effects

Active Publication Date: 2018-03-27

NINGBO POWERWAY ALLOY MATERIAL

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the above deformed zinc alloys do not involve cold heading processing, and their comprehensive properties cannot meet the requirements of cold heading processing. Due to the high performance requirements of cold heading processing for materials, the deformed zinc alloys that can be applied to cold heading processing in the existing technology Alloys not developed

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 5

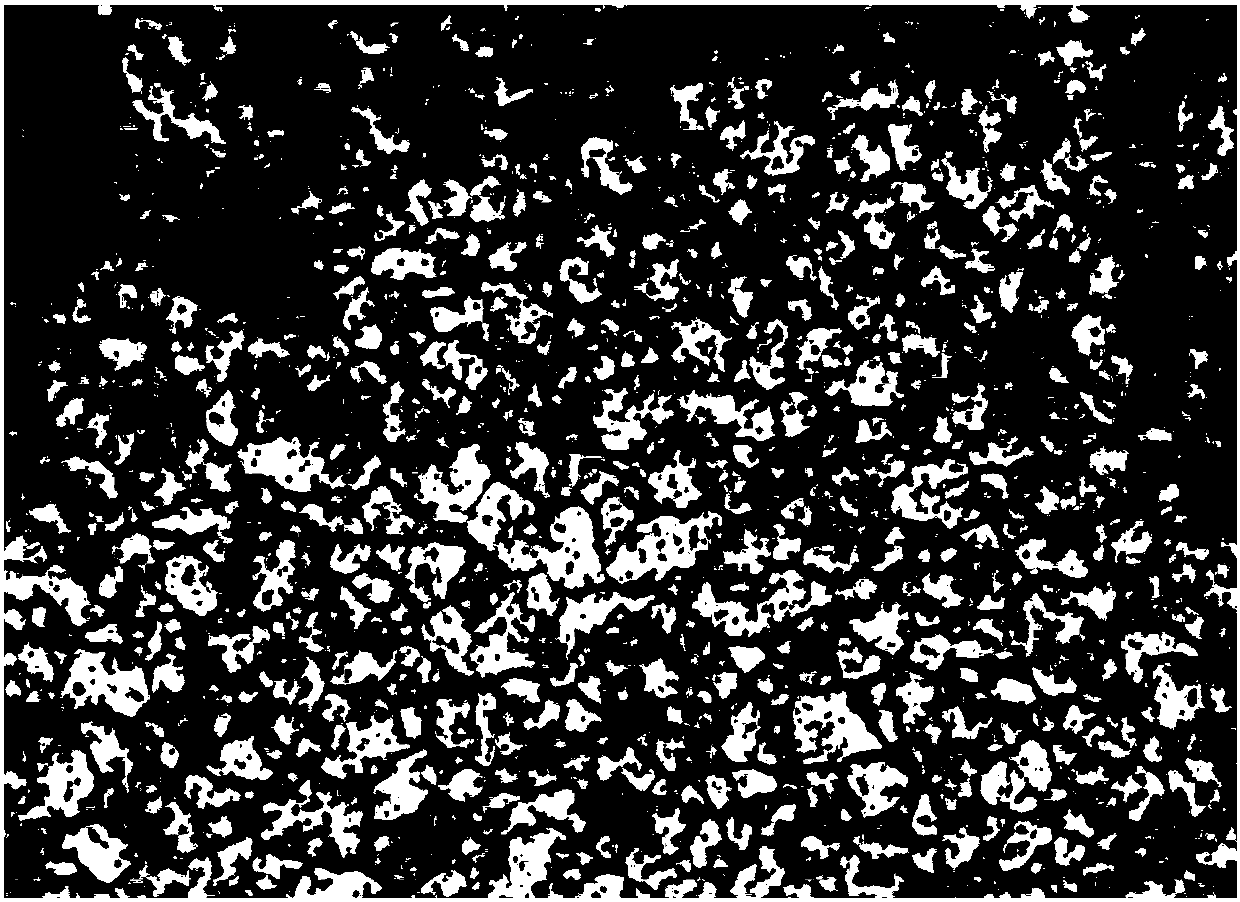

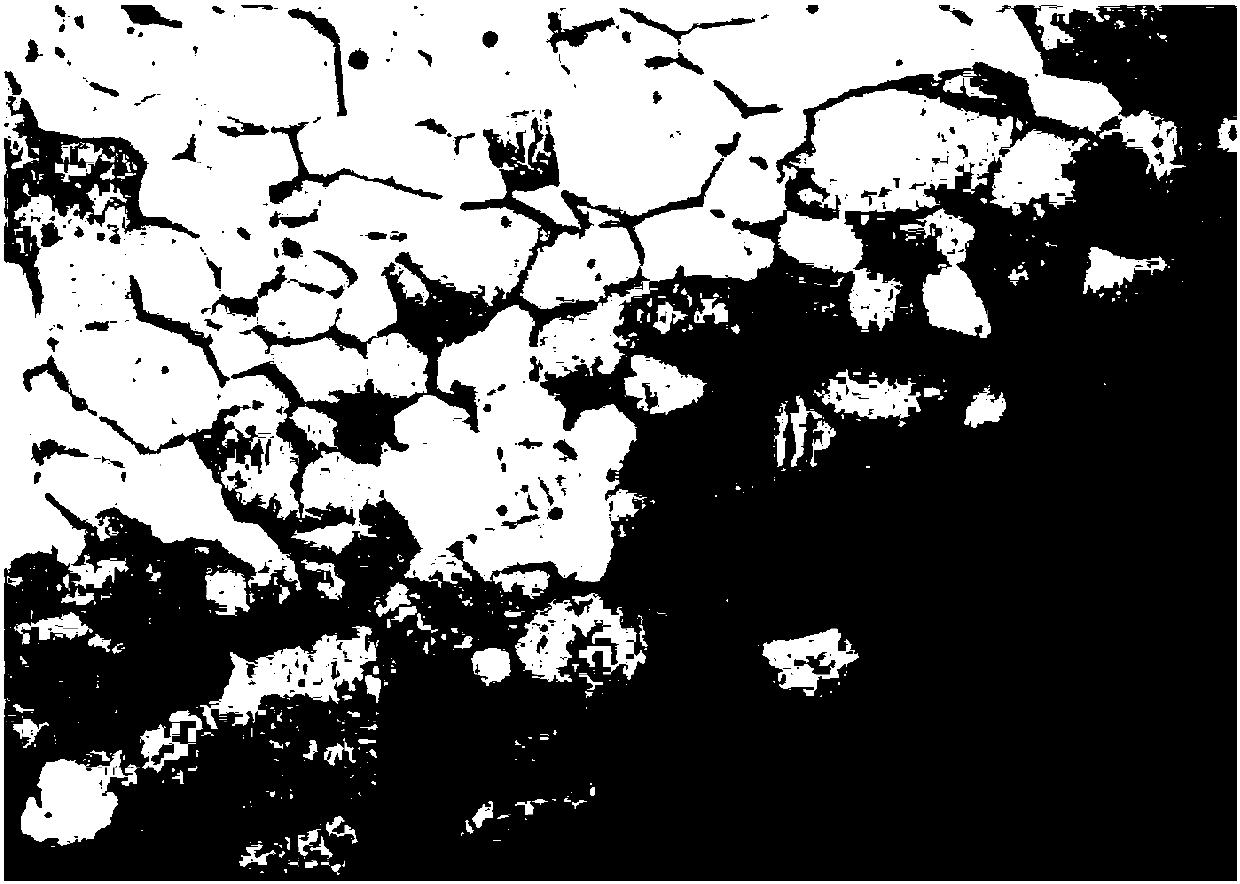

[0036] See the metallographic picture of the microstructure of the wire of Example 5 figure 1 , See the metallographic picture of the microstructure of the wire of Example 8 perpendicular to the machining direction figure 2 , See the metallographic picture of the microstructure of the wire of Example 8 parallel to the machining direction image 3 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Login to view more

Abstract

A deformable zinc alloy capable of being cold headed. The deformable zinc alloy comprises the following components in percentage by weight: 0.01%≤Cu≤5.0%, 0.01%≤Al≤5.0%, and 0.001%≤Mg≤1.0%, with the balance being Zn and inevitable impurities. The microstructure of the deformable zinc alloy uses a single-phase η-phase solid solution structure as a matrix; the volume fraction of the single-phase η-phase solid solution structure in the microstructure of the deformable zinc alloy is 95-99%. The microstructure of the alloy uses a single-phase η-phase solid solution structure as a matrix, the tensile strength of the alloy can reach 280 MPa or more, and the elongation can reach 15% or more, so that sufficient deformability is provided for cold heading processing.

Description

Technical field [0001] The present invention relates to the technical field of zinc alloy and its application, in particular to a deformed zinc alloy with a single-phase matrix structure. The zinc alloy can be processed by cold heading and other cold deformation, and can be specifically applied to various power plugs, terminal posts and other products . Background technique [0002] Cold heading technology is a kind of high-speed deformation cold processing technology. Metal rods and wires are quickly processed into various complex parts through various molds. Compared with traditional turning technology, cold heading can increase the utilization rate of materials, reduce losses, and improve labor efficiency. The cold heading products have uniform and dense structure and have been widely used in various standard products. Therefore, cold heading has become a metal material processing An important means of molding. [0003] Cold heading has high requirements on the performance of ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to view more Application Information

Patent Timeline

Login to view more

Login to view more Patent Type & Authority Patents(China)

IPC IPC(8): C22C18/00C22C18/02C22C18/04H01R4/58H01R13/03

CPCC22C18/00C22C18/02C22C18/04H01R4/58H01R13/03

Inventor 孙文声唐宁冯振仙郭俊陈永力郜晓彬向紫琪傅红青肖金锋

Owner NINGBO POWERWAY ALLOY MATERIAL

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Try Eureka

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap