Evaporation coating device for organic EL element

A technology of evaporative coating and components, which is applied in the field of organic EL component evaporative coating devices, can solve the problems of affecting the coating effect and uneven coating of EL components, and achieve the effects of improving the coating effect, stably evaporating organic matter, and uniform temperature increase

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

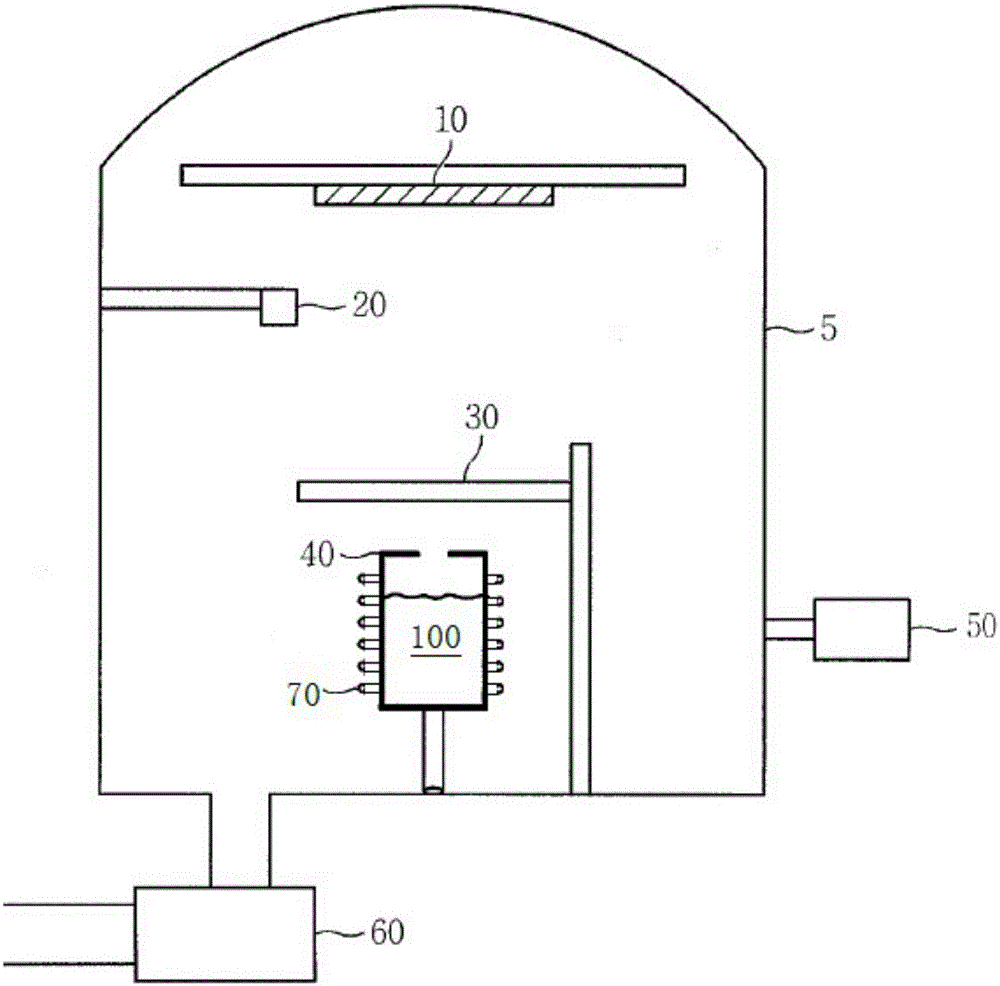

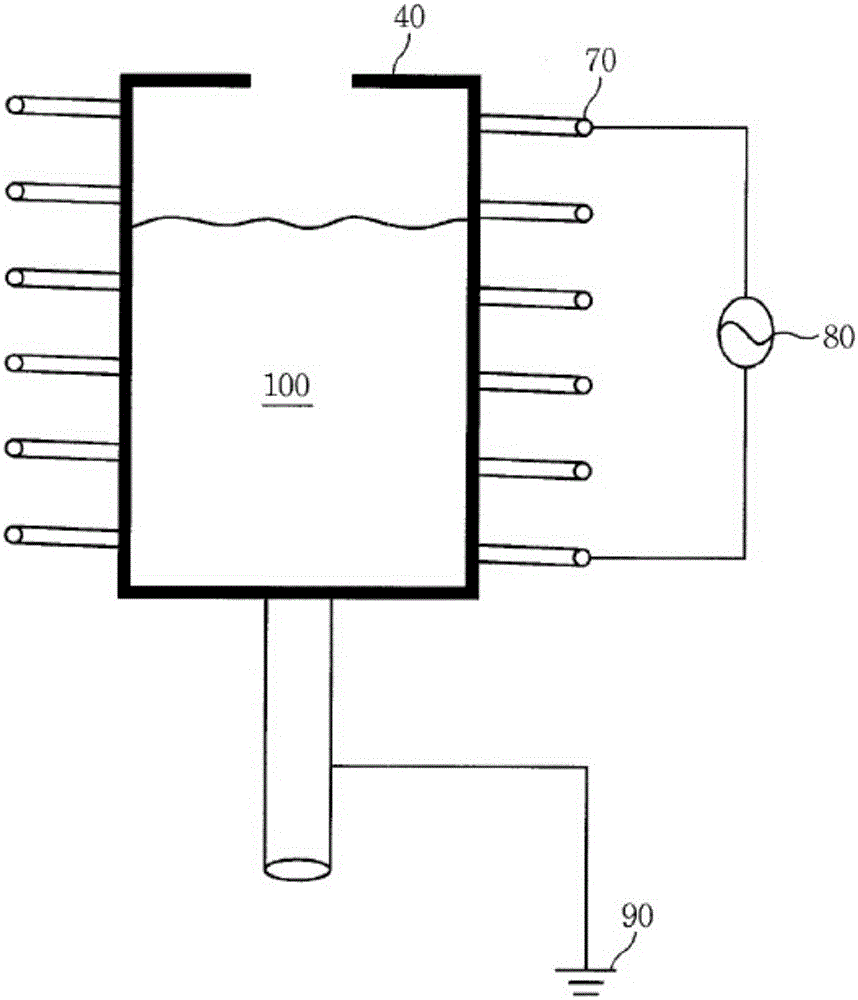

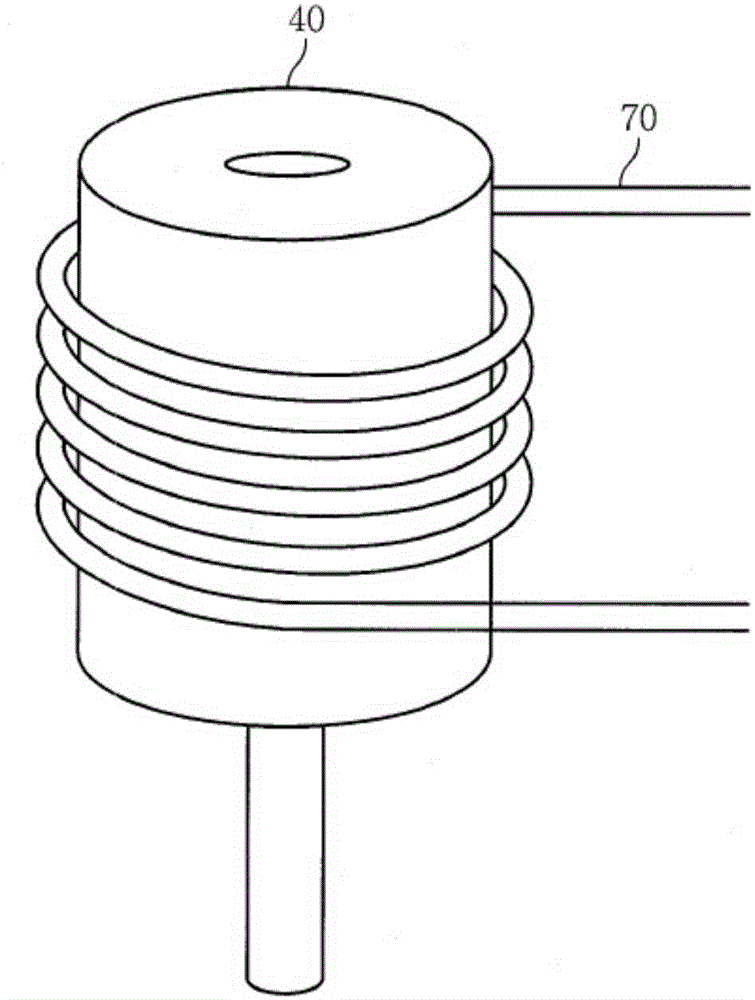

[0017] Such as Figure 1 to Figure 3 As shown, the organic EL element evaporation coating device of the present invention includes a sealed vacuum chamber 5, the bottom of the vacuum chamber 5 is provided with a container 40 for placing organic matter 100, the upper end of the container 40 has an opening, and the substrate 10 is fixed on the opening of the container 40 Above, the heating wire 70 is wound around the container 40. There is a certain distance between the heating wire 45 and the outer wall of the container 40. The heating wire 70 is connected to the AC power supply device 80, and the container 40 is connected to the ground power supply 90. The AC power supply device 80 can Sparks are prevented from being generated between the heating wire 70 and the container 40 .

[0018] Vacuum chamber 5 is also connected with vacuum pump 60 and vacuu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com