Assembly type spring energy dissipation cushion protecting structure for preventing landfall and rockfall of top of shed chamber

A protective structure and assembled technology, which is applied in the direction of protective equipment, underwater structures, infrastructure engineering, etc., can solve the problems of reducing the self-weight of the energy-dissipating cushion on the top of the shed, the weight of the cushioning cushion, and the poor cushioning effect , to achieve the effect of ensuring normal operation, reducing construction difficulty and ensuring safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

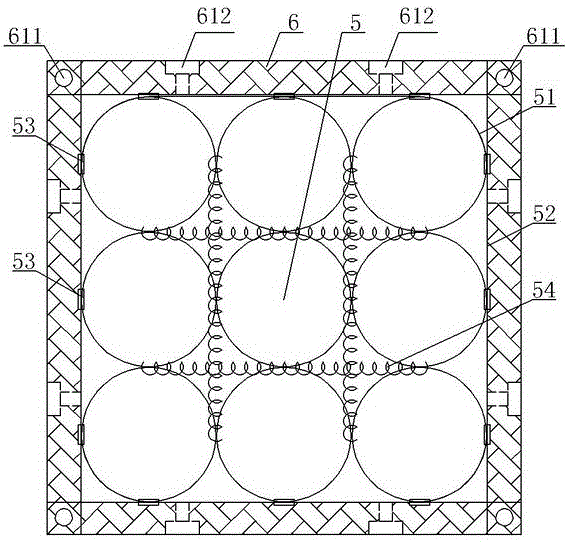

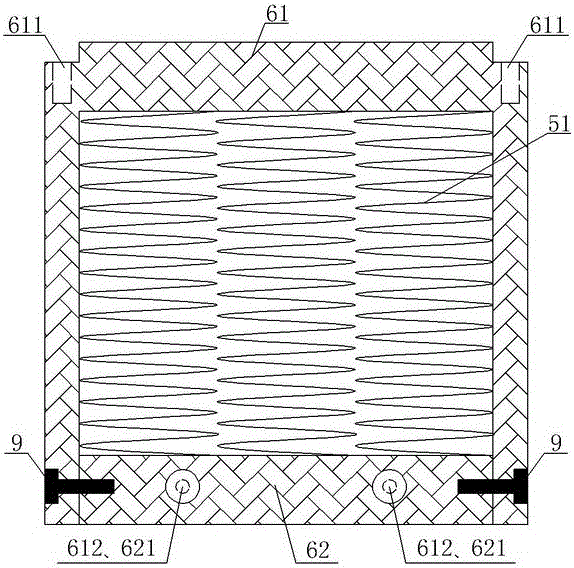

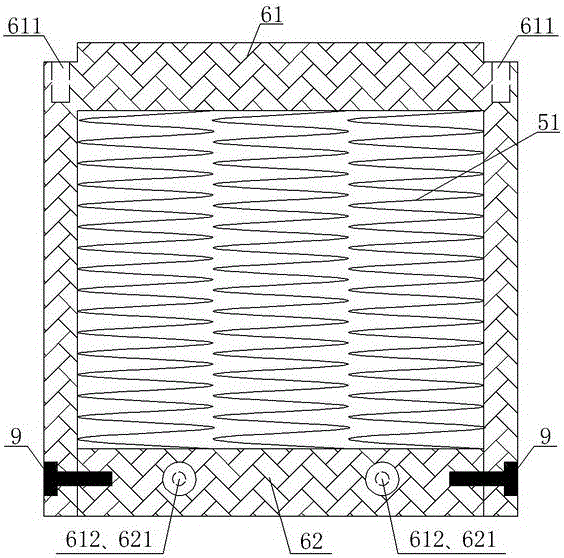

[0031] Below in conjunction with accompanying drawing and specific embodiment, make further description to the protective structure of assembled light-duty spring energy-dissipating cushion layer of the present invention:

[0032] Figure 1 to Figure 3 The structure of the spring energy dissipation block is given. It can be seen from the figure that the spring energy dissipation block is composed of a spring frame 5 outsourcing the rubber shell 6. The prepared spring frame 5 is placed in the rubber box 61, and the rubber cover 62 and the rubber box 61 are connected with the assembly screws 9 through the assembly holes 612 and 621. Assembled into a whole to form a spring energy dissipation block sealed with a rubber casing 6 . In order to ensure the integrity of the rubber shell and the firmness of the connection, gaskets should be added to the screw connections.

[0033] Figure 4 , Figure 5 The structure of the spring frame 5 is given, wherein the spring frame 5 is compo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com