Liftable post-cast strip template structure and system and construction method thereof

A technology of post-casting strips and templates, which is applied in basic structure engineering, underwater structures, artificial islands, etc., can solve problems such as incomplete scaffolding, adverse effects, and inconvenient removal of construction waste, and achieve sufficient working space, simple manufacturing, and The effect of small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

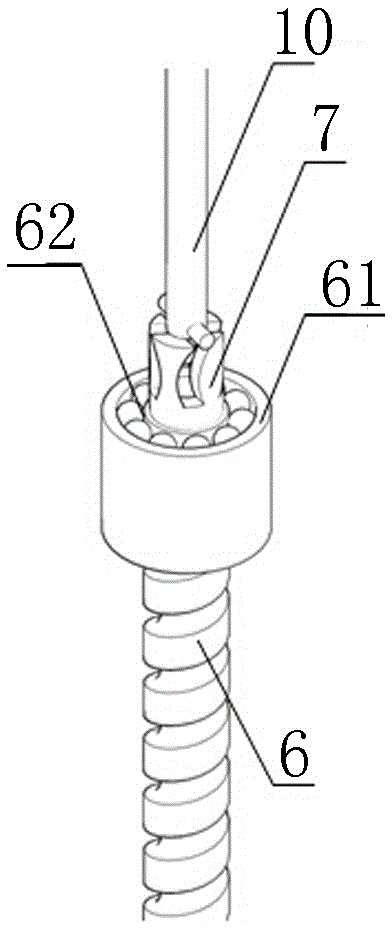

[0040] The purpose of the present invention is to overcome the deficiencies of the existing technology, to provide a formwork structure and system of the post-casting belt that can be lifted and lowered, and its construction method. Without removing the support system of the post-casting belt, it can be raised and lowered by adjusting the lead screw 6 The formwork structure of the pouring belt solves the inconvenient and incomplete removal of construction waste at the post-casting belt; and solves the adverse effects of scaffolding on subsequent construction operations during the construction of the post-casting belt.

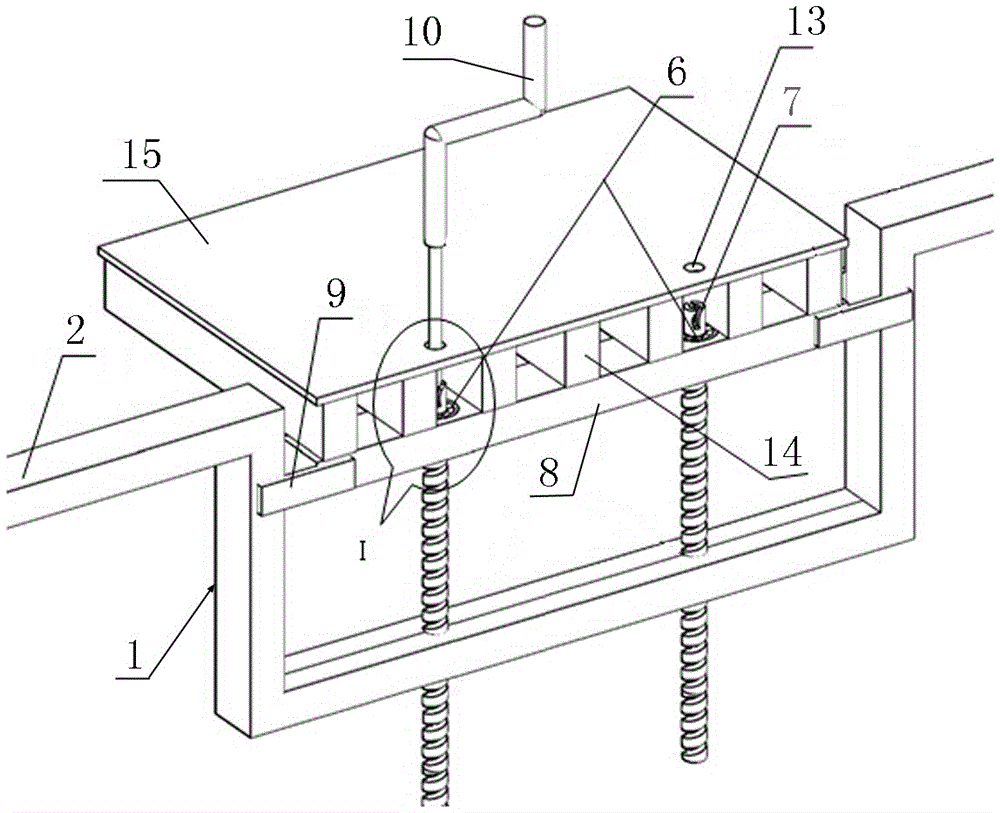

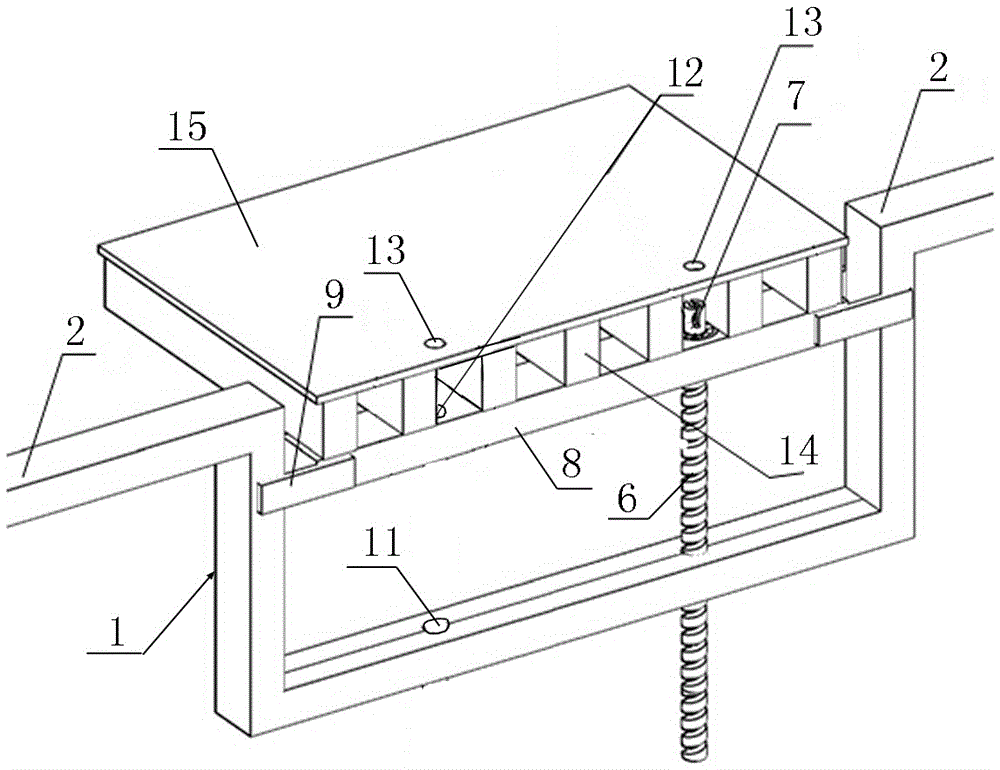

[0041] Such as figure 1 and figure 2 As shown, this liftable post-casting strip formwork structure includes a formwork horizontally arranged at the post-casting belt; it also includes a formwork support and a lead screw 6 connected between the formwork and the formwork support; the formwork support is located at the At the bottom, it is arranged in parallel a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com