Integral sliding friction pendulum isolation layer on the bottom surface

A technology of sliding friction and shock-isolation layer, which is applied in the direction of earthquake-proof, protective buildings/shelters, building components, etc., can solve the problem that the shock-isolation bearing is difficult to meet the anti-ultra-large earthquake performance of the shock-isolation building, and achieve easier reset, overall good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

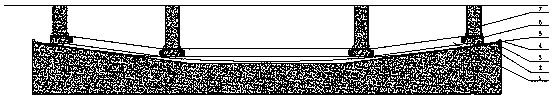

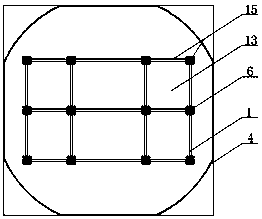

[0025] Specific implementation mode one: as Figure 1-2 As shown, the bottom integral sliding friction pendulum shock-isolation layer of this embodiment consists of a bottom spherical shell 3 and an upper spherical frame 15, wherein:

[0026] The lower side of the bottom spherical shell 3 is integrated with the concrete foundation or the lower structure 2, and the upper surface is an arc-shaped spherical surface 13 with a large span and a large curvature radius;

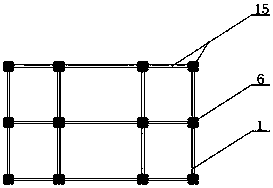

[0027] The upper spherical frame 15 is connected by several sliders 5, connecting beams 1, load-bearing columns 7, and connecting members 6. The lower part of the connecting members 6 is welded with the sliders 5, and the side of the connecting members 6 is connected with the connecting beams 1. The connecting members 6. The upper part is connected to the upper structure through the load-bearing column 7, and the upper structure is connected to the shock-isolation layer by means of the load-bearing column 7. The slid...

specific Embodiment approach 2

[0029] Specific implementation mode two: as Figure 3-7 As shown, in this embodiment, the cross-section of the connecting member 6 is box-shaped, the interior is filled with concrete and embedded with stud bolts 9, the lower cover plate of the connecting member 6 is welded to the top of the slider 5, and the side of the connecting member 6 passes through the beam end 8 bolts of the angle steel plate are connected with the welding at the flange and the I-shaped connecting beam 1 is bolted and welded to form the upper spherical frame 15 as a whole.

[0030] The upper part of the connecting member 6 is provided with a circular or rectangular steel sleeve 17, and concrete is poured into the steel sleeve 17 to form a load-bearing column 7 connected to the upper structure; the upper surface cover plate of the connecting member 6 is welded to the combined column cover plate 16 on the bottom surface of the steel sleeve 17 , The outer side of the steel sleeve 17 is provided with a colu...

specific Embodiment approach 3

[0032] Specific implementation mode three: as figure 1 , 2 , 7, in this embodiment, the span of the bottom spherical shell 3 is greater than that of the upper spherical frame 15, and the height of the edge is close to or reaches the ground surface, and a limit ring 4 is arranged on the edge of the arc-shaped spherical surface 13, and the uppermost portion of the arc-shaped spherical surface 13 A wind-resistant ring 11 is provided outside the balance position of the outer slide block 5 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com