Filling type shear wall welded in staggered mode

A shear wall and infill technology, applied in the direction of walls, building components, buildings, etc., can solve the problems of mismatching characteristics of residential apartments, difficult modular production, consumption of large wood, etc., to achieve convenient module division and less impact on welding quality , Reduce the effect of construction links

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Specific embodiments of the present invention will be further described in detail below.

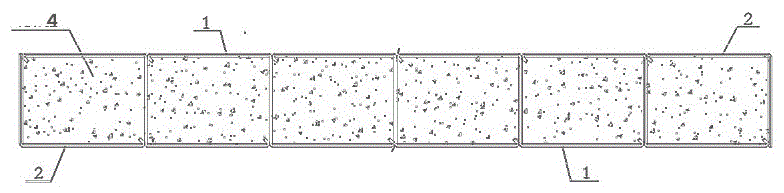

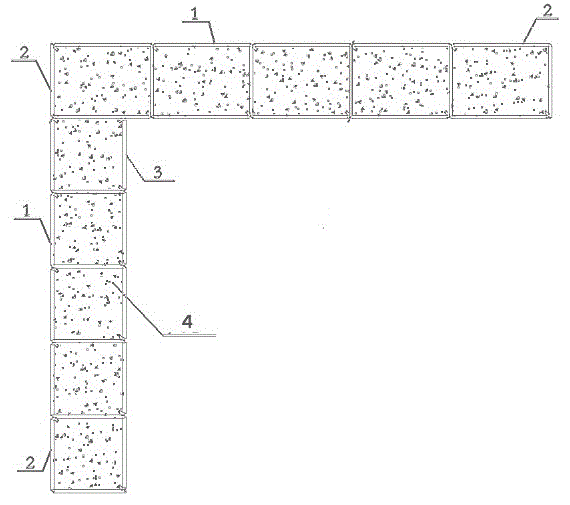

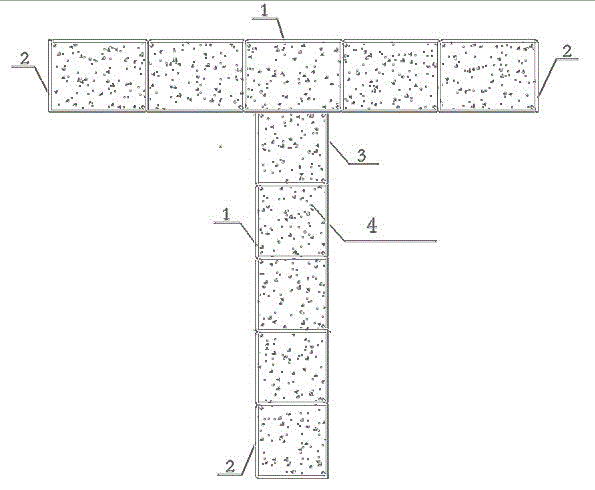

[0029] Figure 1 to Figure 8 As shown, a staggered welded filled shear wall of the present invention is formed by splicing a plurality of Z-shaped steel profiles 1 sequentially in the same direction, wherein the Z-shaped steel profiles 1 include an upper flange 101 , a web 102 and a lower flange 103 . The web 102 and lower flange 103 of the previous Z-shaped steel section 1 and the upper flange 101 and web 102 of the latter Z-shaped steel section 1 together form a square cavity 4, and concrete is poured in the cavity 4. The Z-shaped steel profile 1 at the front end and the rear end are connected with the L-shaped steel profile 2 or the straight steel plate 3 to form a cavity 4 . The Z-shaped steel profile 1, the L-shaped steel profile 2 or the straight steel plate 3 are connected by welding. When the Z-shaped steel profiles 1 are spliced, the welds are not in the same section, b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com